Folding-type rotary aluminum-plastic chair

A folding, aluminum-plastic technology, applied to folding chairs, chairs, detachable chairs, etc., can solve the problems of inability to adjust the height and folding, take up a large space, and cannot be folded, so as to achieve convenient storage, transportation and portability. The effect of small packaging volume and convenient folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail by the following examples.

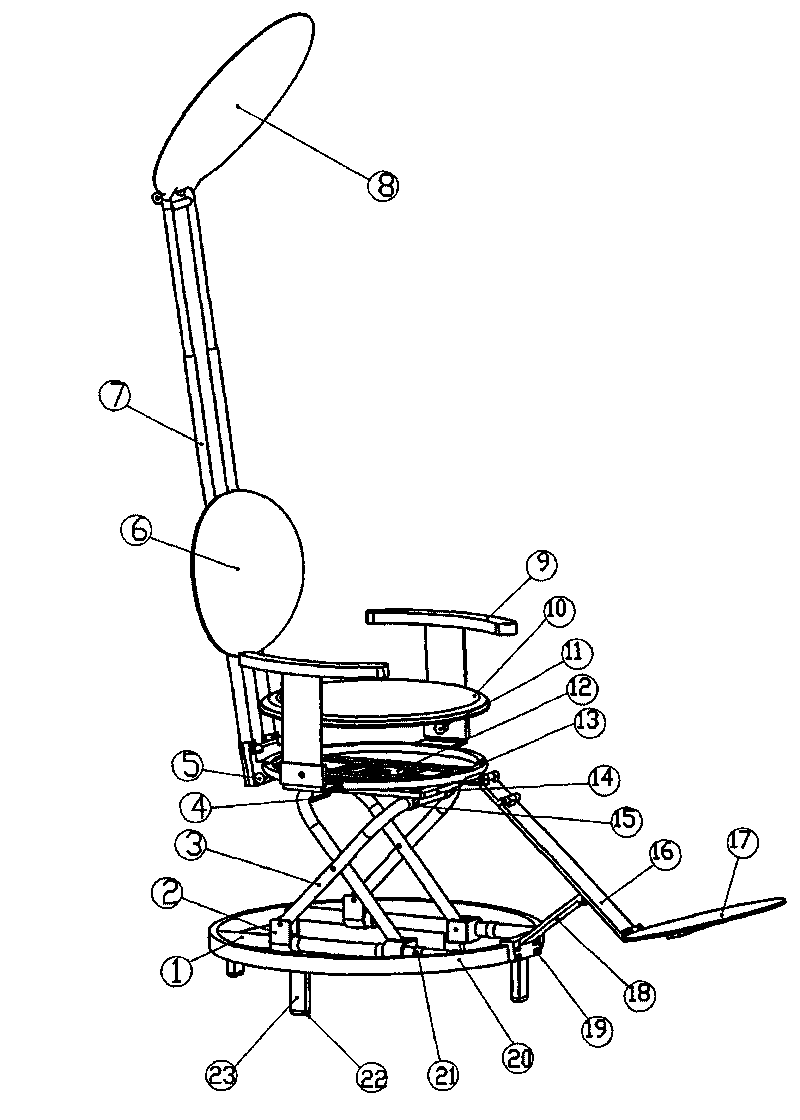

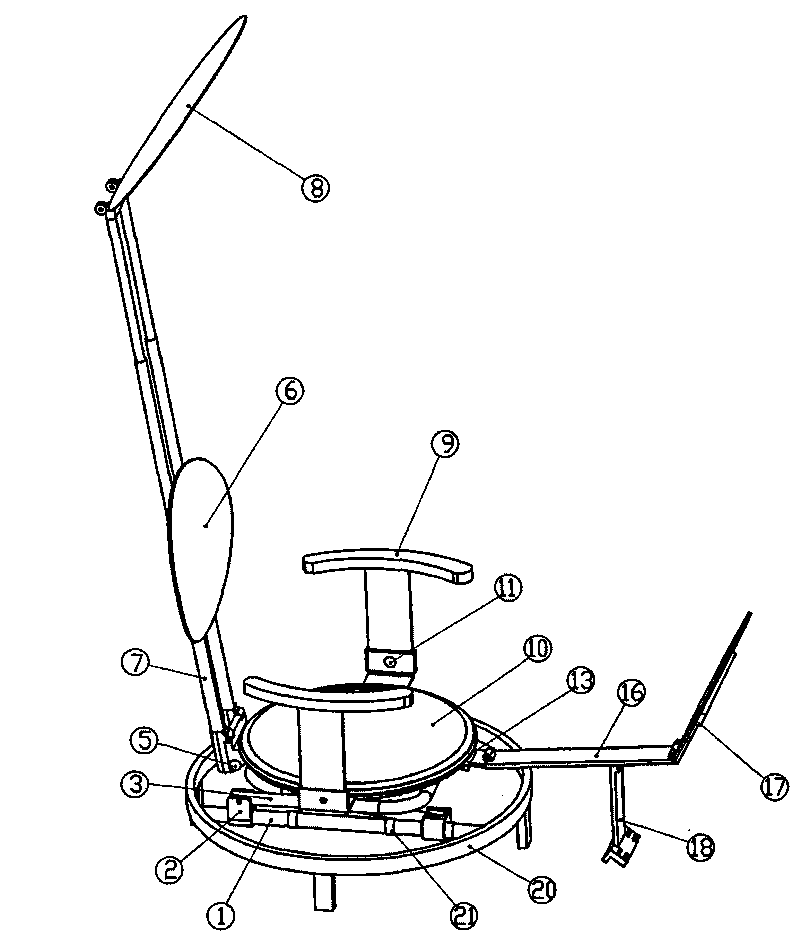

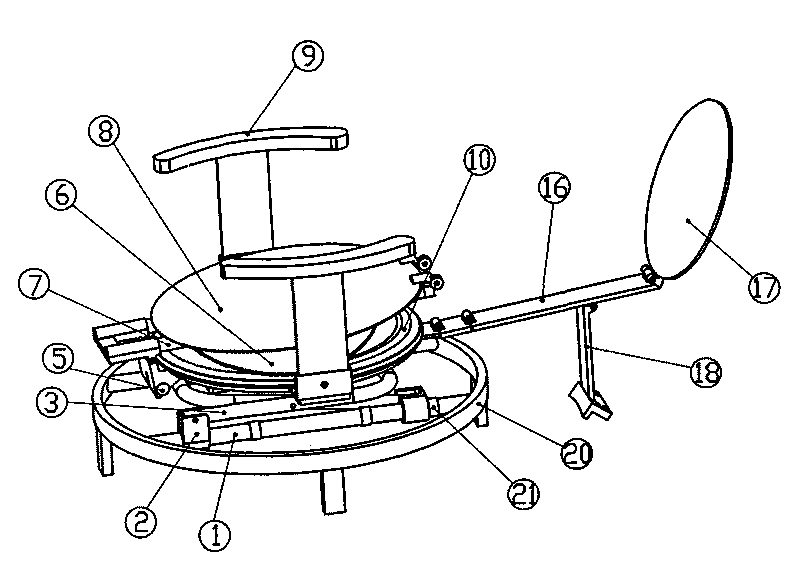

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a foldable rotating aluminum-plastic chair is mainly composed of a guide rail 1, a slider 2, a bracket 3, a seat positioning lock 4, a back positioning lock 5, a back plate 6, a back telescopic tube 7, a baffle plate 8, an armrest 9, a seat Plate 10, armrest positioning lock 11, rotating bearing 12, seat plate fixing ring 13, rotating bearing fixing plate 14, pressure block 15, pedal connecting plate 16, pedal 17, pedal supporting plate 18, bearing 19, base fixing Circle 20, slide block limit circle 21, foot plug 22, supporting pin 23 form. Swivel bearing 12, swivel bearing fixing plate 14, pressure block 15, seat positioning lock 4, bracket 3 of cross hinged rod structure, slider 2, slider limit ring 21, guide rail 1, base fixing ring 20, support feet 23. The foot plug 22 forms the base assembly; the seat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com