Cold-rolling mill

A technology of cold-rolled pipe mills and racks, which is applied in metal rolling and other directions, and can solve the problems of poor work reliability, reduced quality of rolled pipes, and short service life, so as to achieve improved reliability, extended service life, and guaranteed deployment position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

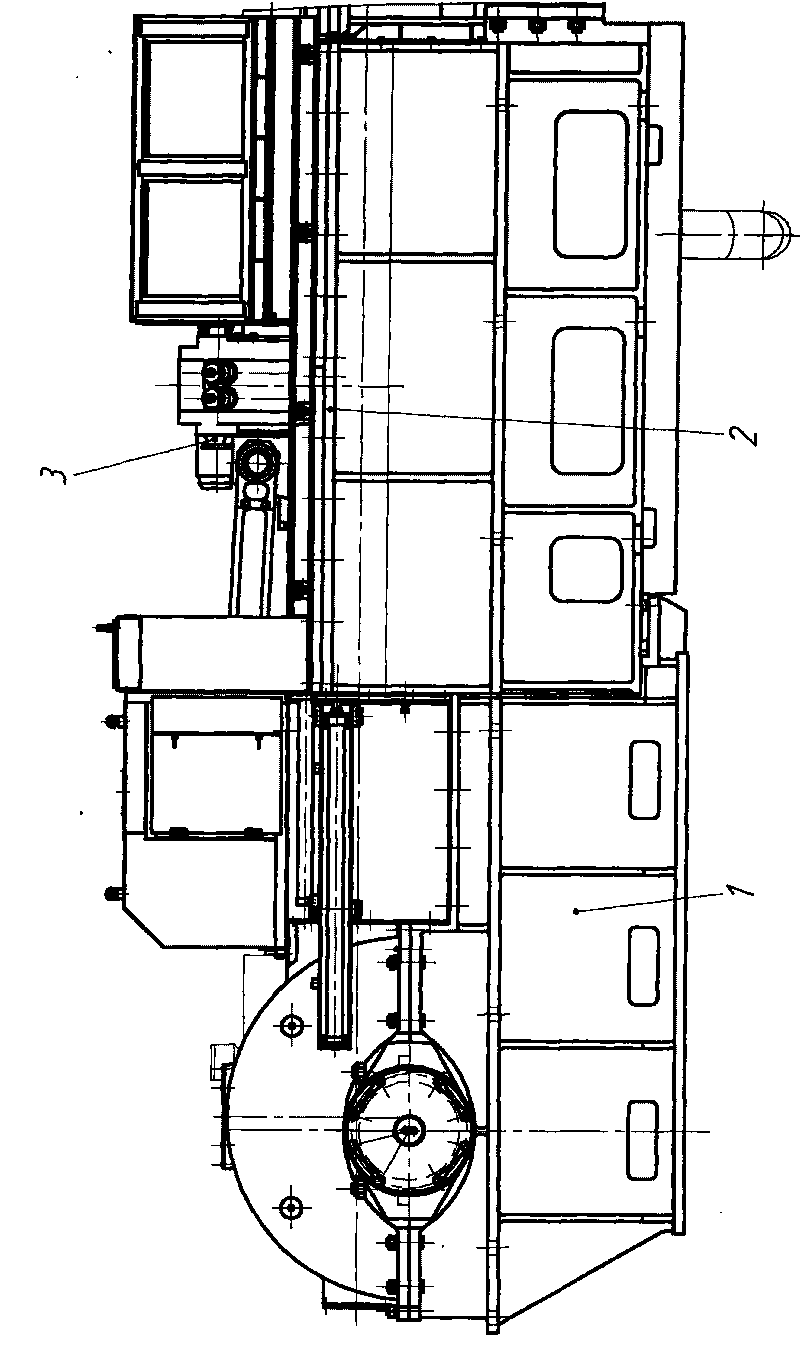

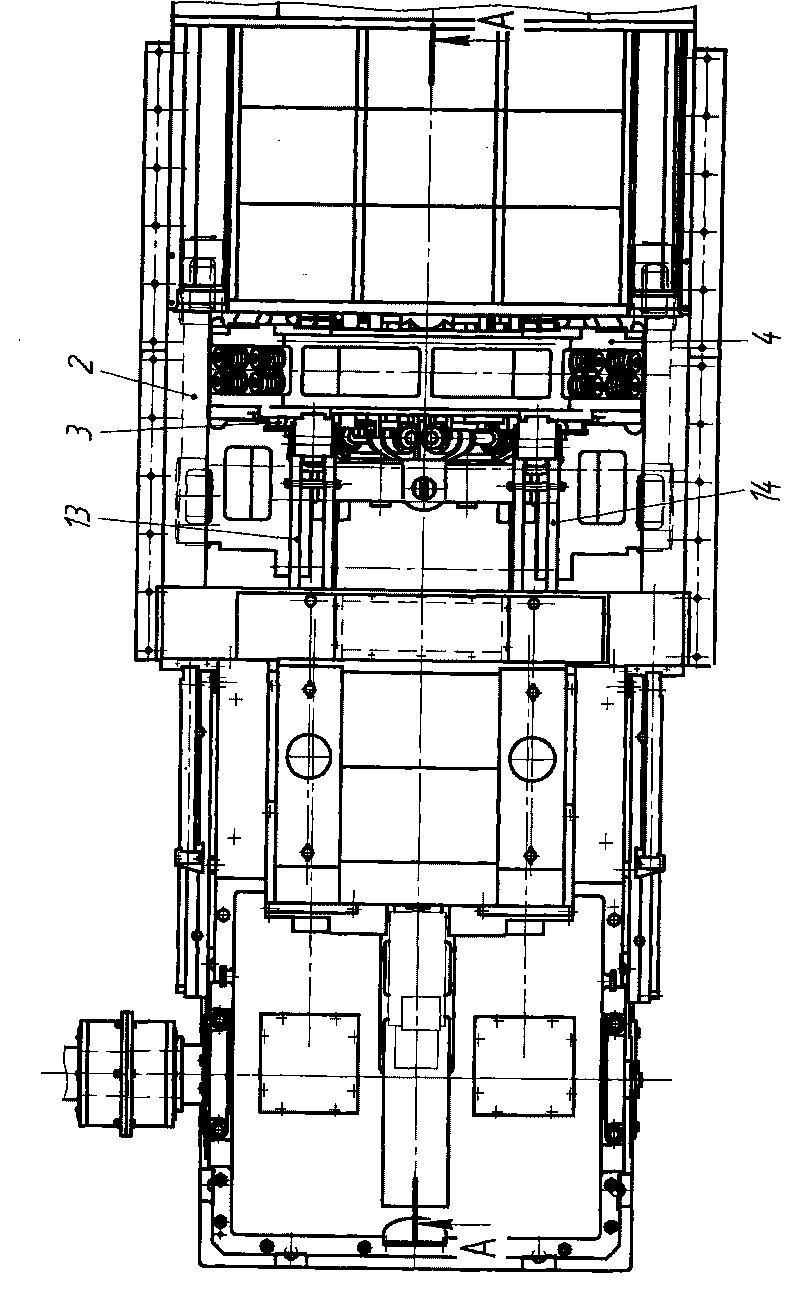

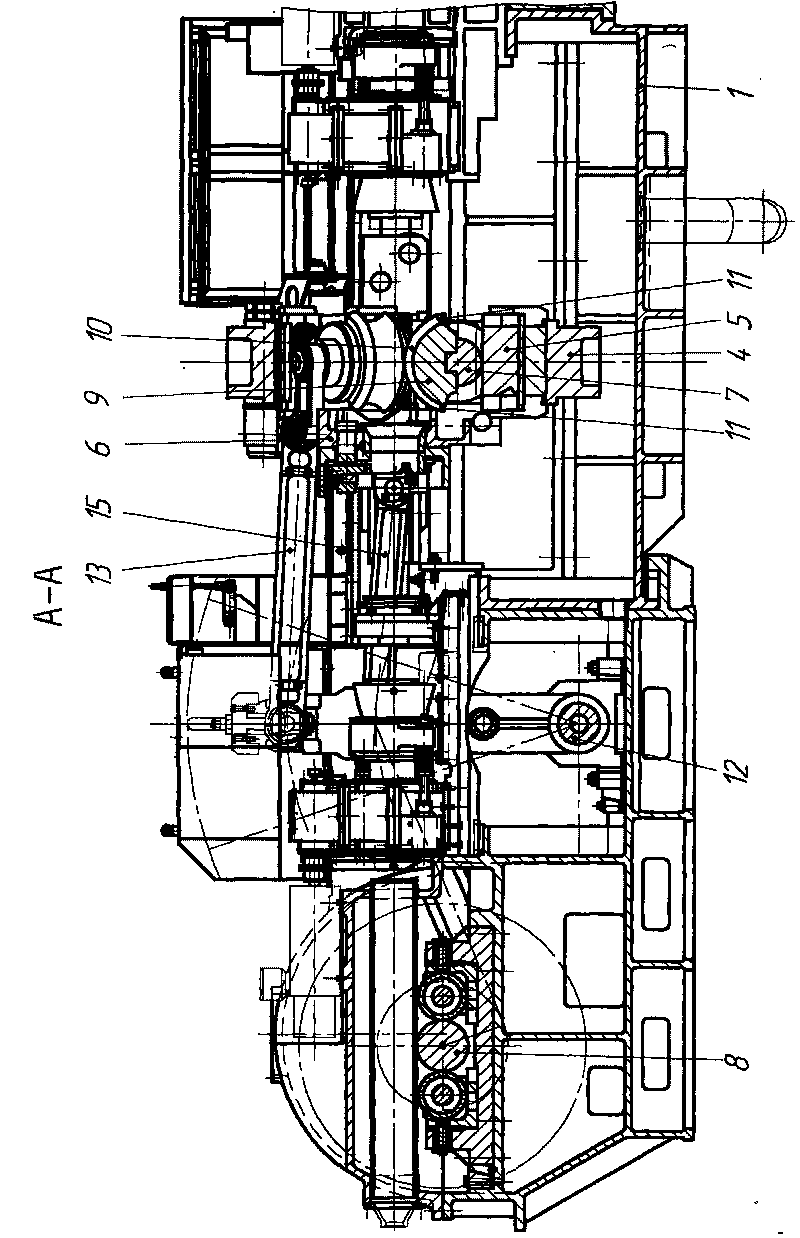

[0016] The frame 1 included in the cold rolling mill has a guide device 2 and a driving device 8 for moving the work frame 3 forward and backward. The work frame 3 is installed on the guide device 2. The work frame 3 has a movable power base Track 5, mobile roll box 6 and work roll 7 installed inside. The movable roll box 6 has a replaceable die 9, and the die 9 is provided with a rolling groove 10 with a gradually changing circumferential section, and feeding and turning openings 11 are provided at both ends of the rolling groove 10 having a gradually changing circumferential section. The rolling groove 10 with gradually changing circumferential section is connected to the base surface a of the die 9 at a certain angle α, the angle α is adjustable, in order to roll steel pipes with different diameters, it can move within the length range of the roll box 6 Guarantee the expanded state of the rolling groove 10 with feeding and turning openings 11 at both ends.

[0017] In orde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap