Robot for punching positioning holes on circuit board

A technology for positioning holes and robots, applied in printed circuits, boring/drilling, printed circuit manufacturing, etc., can solve the problems of monotonous manual operation process, high labor cost, high labor intensity, etc. Production efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

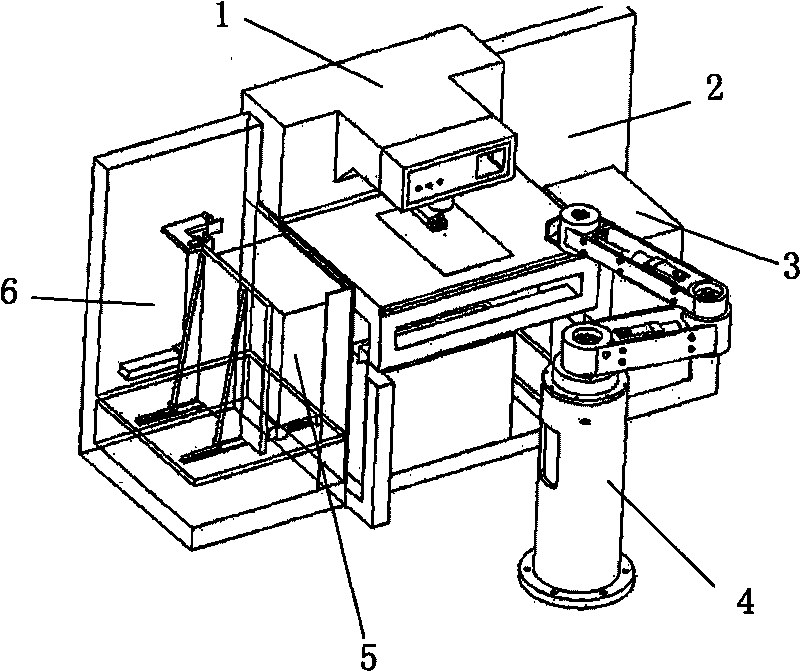

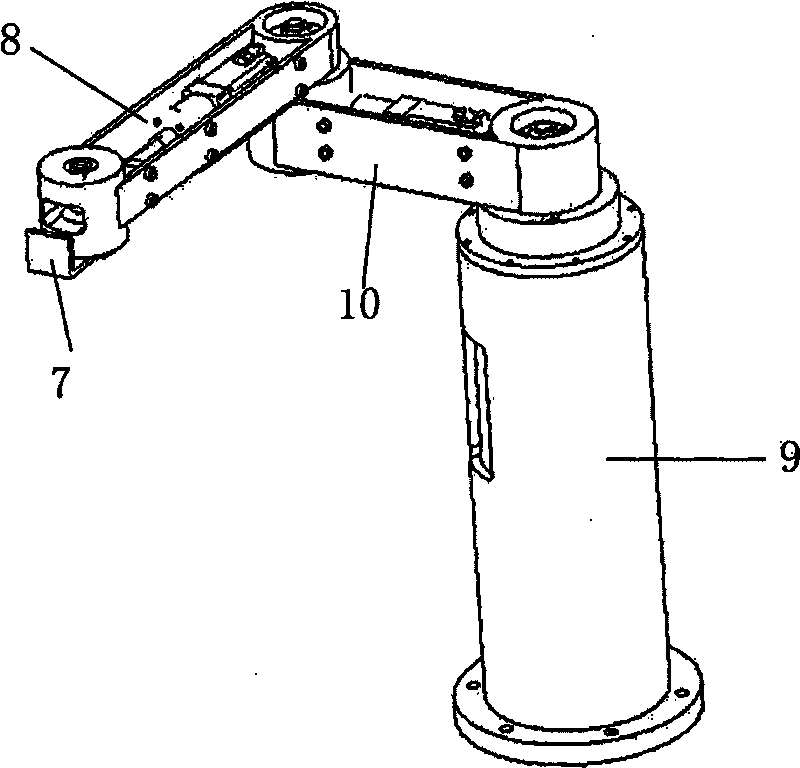

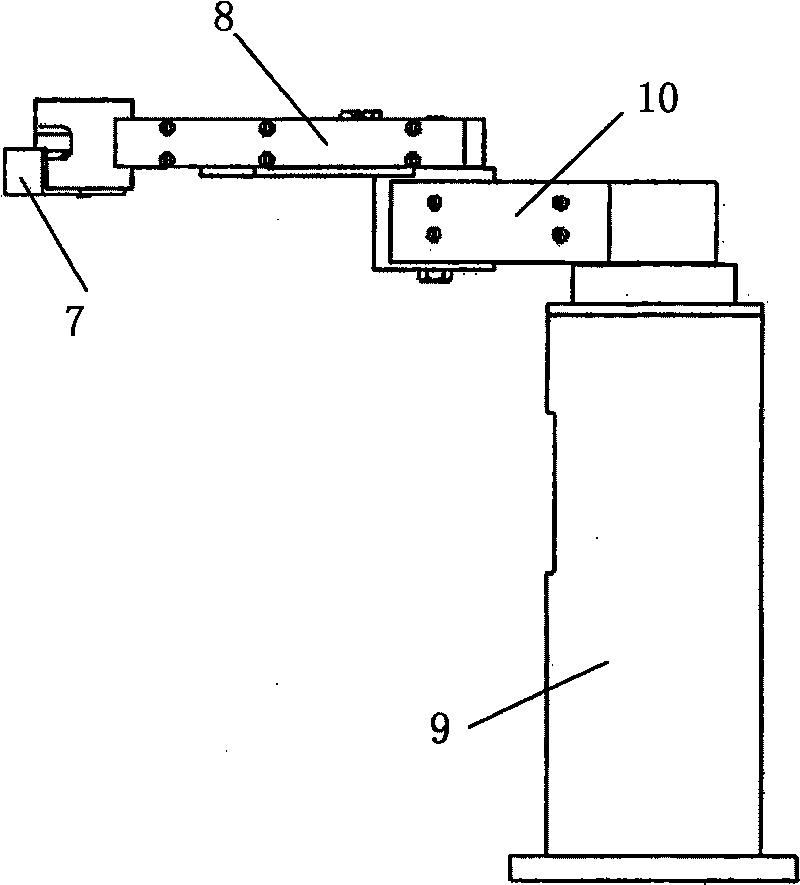

[0023] like figure 1 As shown, the robot body 4 of the present invention is arranged around the punching machine 1 (fixed on the position designed before the punching machine 1), by taking the positioning hole circuit board 5 to be processed from the feed bin 6 to the punching hole The processing station of machine 1 carries out punching processing, becomes and completes the positioning hole circuit board 3, then takes the completed positioning hole circuit board 3 to the receiving bin 2 for storage. In the feeding bin 6, the positioning end of the unpunched circuit board to be processed with positioning holes 5 abuts against the right-angle stopper on the feeding bin 6, so that each circuit board is positioned. There is a lifting mechanism in the feeding bin 6, which can make the circuit board positioned with the right angle stopper vertically lift up and down, and the lifting mechanism makes the circuit board on the top reach a preset fixed height. Then the circuit board po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap