Vehicle front suspension control arm

A control arm and front suspension technology, which is applied in the field of automobile front suspension system, can solve the problems that the lateral stiffness of the front suspension cannot be effectively improved, the handling and comfort of the vehicle are affected, and the operation stability of the whole vehicle is affected. , to achieve the effects of easy installation, improved lateral rigidity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

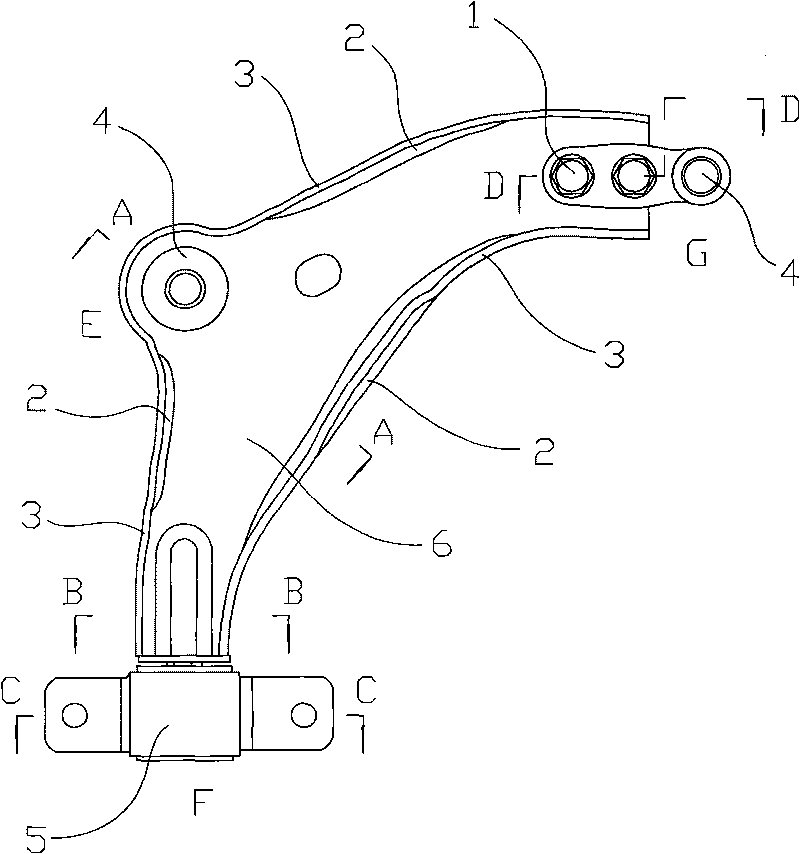

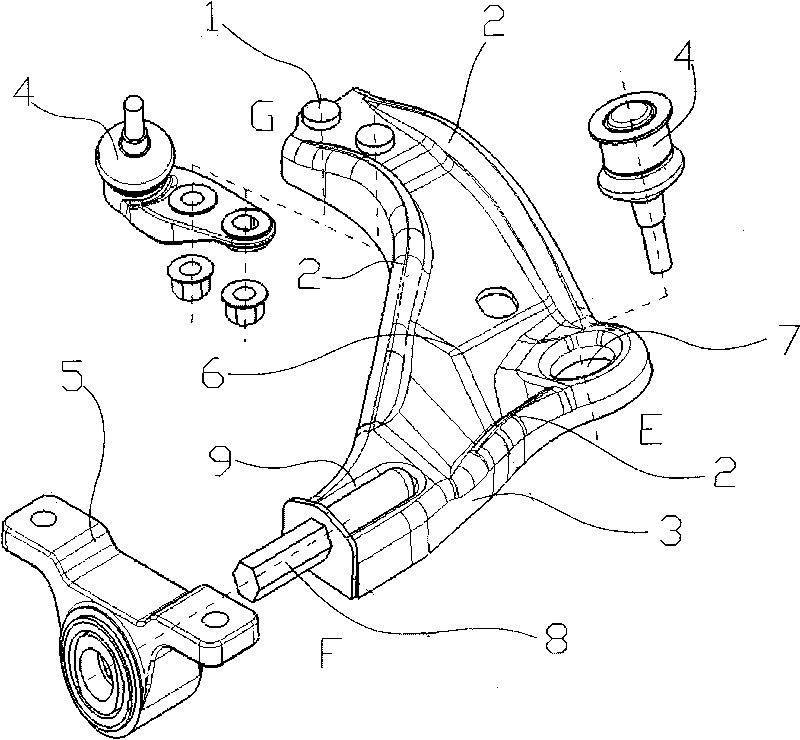

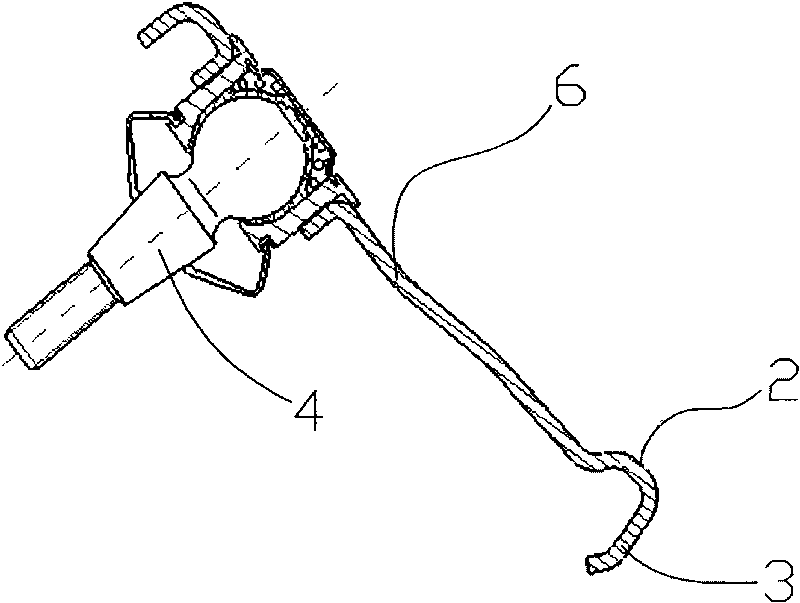

[0021] Such as Figure 1 to Figure 6 As shown, the front suspension control arm of the automobile is a sheet metal part stamped and formed from a sheet metal, and includes a control arm main body 6. At the rear connection end F of the frame, a flange 3 is arranged at the edge between each two ends, and a ball stud assembly 4 is fixed with a bolt 1 on the connection end G of the control arm main body 6 and the steering knuckle; the control arm main body 6 is on its A flange hole 7 is opened on the front connection end E of the vehicle frame and a ball stud assembly 4 is fixed therein. The ball stud assembly 4 is located in the flange hole 7 and is interference fit with the control arm main body 6; A fixing groove 9 is arranged on the rear connection end F of the vehicle frame and a hydraulic bushing 5 is fixed therein. The hydraulic bushing 5 is welded in the fixing groove 9 through a fixing shaft 8 .

[0022] The control arm main body 6 is provided with a reinforcing rib 2 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com