Headlamp and rearview mirror wiper blade structure for automobile

A wiper structure and rearview mirror technology, which is applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve the problems of small installation space, large installation space, complex structure, etc., and achieve simple structure, Small installation space and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

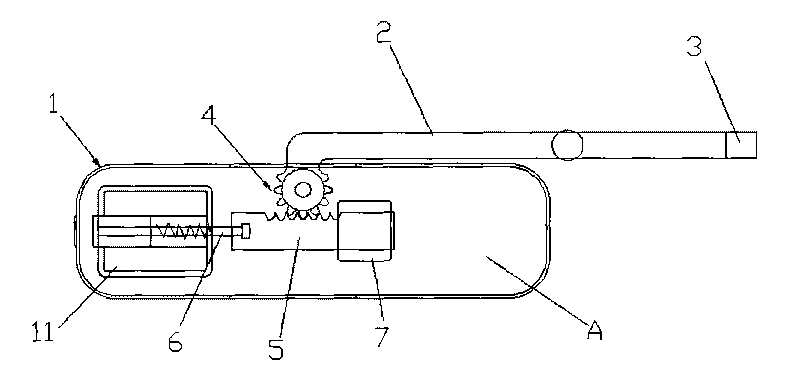

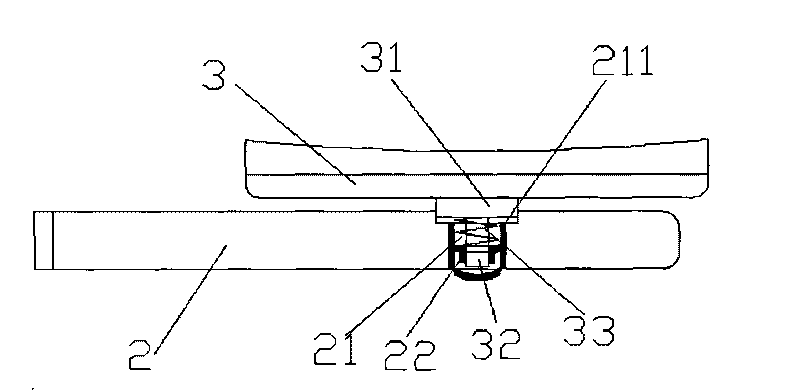

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, the automobile headlight of the present invention and rearview mirror wiper structure comprise transmission device 1, swing arm 2 and wiper blade 3, transmission device 1 is the dynamic mechanism that is made up of a magnetic transmission device 11, in swing arm 2 The lower end is set into a gear shape 4, and a connecting block 5 with a toothed surface is arranged corresponding to the gear shape. The connecting block 5 is provided with a guide fixing block 7 with a groove, and the connecting block 5 is connected to the magnetic driver through a connecting rod 6. 11. Make the magnetic actuator 11 horizontally move left and right along the groove of the fixed block 7 through the connecting block 5 and form a gear-type transmission connection with the tooth shape at the lower end of the swing arm 2, so that the drive 1 drives the swing arm 2 to form left and right swings Function. A screw rod 32...

Embodiment 2

[0025] Such as Image 6 As shown, the driver 1 of the car headlight and rearview mirror wiper structure of the present invention is a power mechanism composed of two magnetic drivers 11, and the power directions of the two magnetic drivers 11 are reversed. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com