Hoisting system of overhead crane

A crane and telescopic boom technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve problems such as unbearable load, achieve large hoisting capacity, increase the scope of application, and reduce storage costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

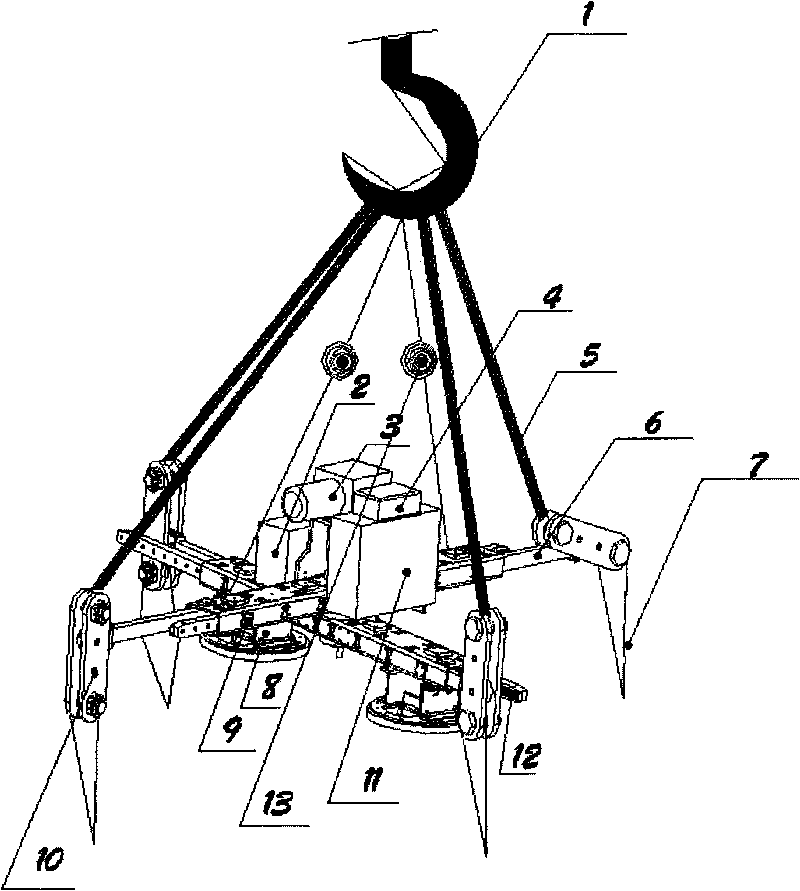

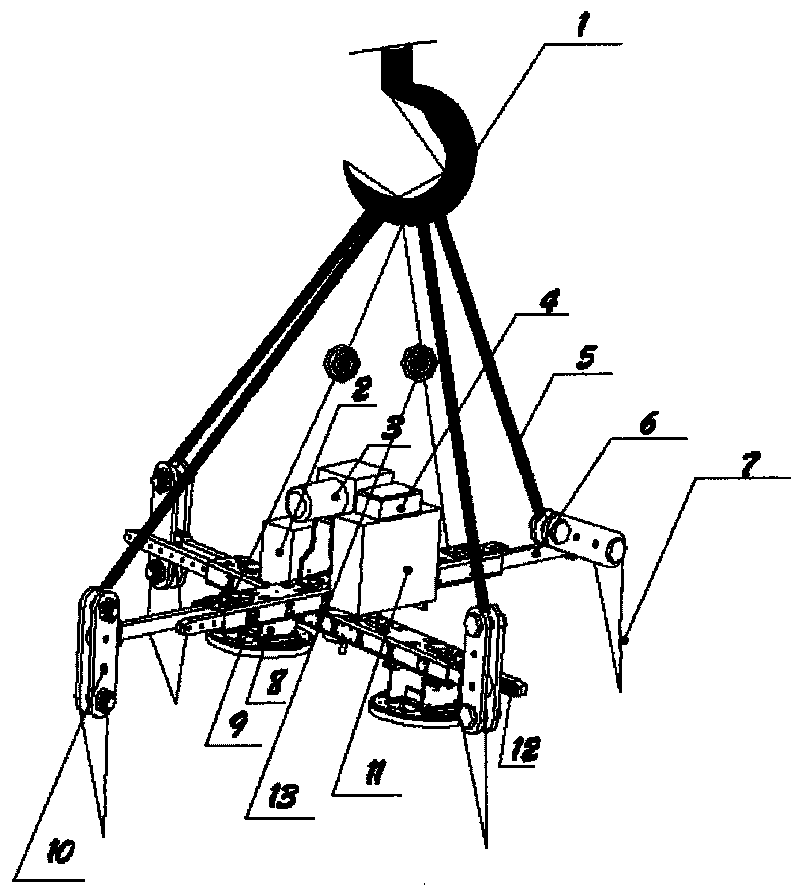

[0022] see figure 1 As shown, the present invention relates to a crane hoisting system for storing large stamping dies of automobiles, which includes a power supply 2, a motor 3, an inverter 4, an upper wire rope 5, a telescopic arm assembly 6, a lower wire rope 7, a support Disc 8 , rolling bearing 9 , connecting plate 10 , electric box 11 , rack 12 and balancer 13 .

[0023] Wherein each telescopic arm assembly 6 all comprises two telescopic arms, wherein one telescopic arm is accommodated in the other telescopic arm, and can carry out telescopic back-and-forth movement relative thereto to adjust the length of the entire telescopic arm assembly 6 . In this embodiment, there are 4 telescopic arm assemblies 6 arranged symmetrically in a cross. A power supply 2 , a motor 3 , an inverter 4 and an electric box 11 electrically connected are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com