Colored coating and electronic product using same

A technology of color coating and electronic products, applied in the direction of layered products, layered product processing, coating, etc., can solve problems such as weak adhesion, damage to health, ugly appearance of electronic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The color coating provided by this technical solution and its manufacturing method will be further described below in conjunction with the drawings and embodiments.

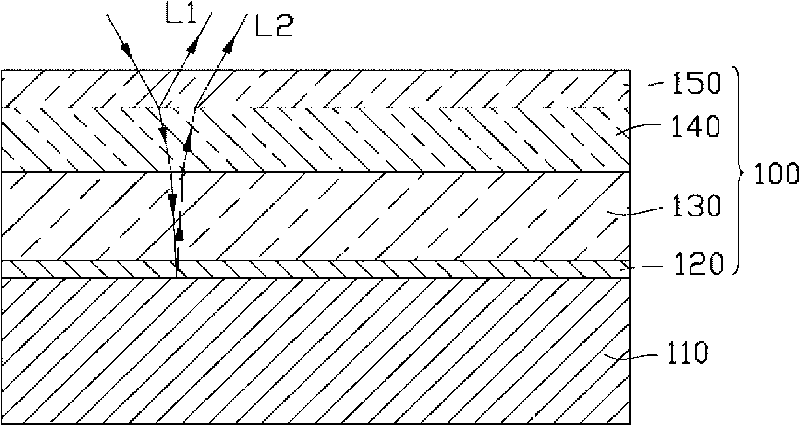

[0013] See figure 1 , The color coating 100 provided in the first embodiment of the technical solution includes an adhesion layer 120, a color control layer 130, a reflective layer 140, and a corrosion-resistant layer 150 stacked in sequence.

[0014] The color coating 100 is formed on the outer surface 111 of the substrate 110. The base 110 may be a variety of products whose outer surface is to be colored, such as the housing of various electronic products. The base 110 may be made of various materials, such as glass, metal, ceramic, alloy, glass ceramic, and plastic. The plastic may be polycarbonate or polymethyl methacrylate or the like.

[0015] The material of the adhesion layer 120 is metallic chromium, and the thickness of the adhesion layer 120 is 0.3 to 10 nanometers, preferably 0.3 to 1.0 nanometers. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com