Let-off device of loom using positive easing mechanism

A technology of loose warp mechanism and loom, which is applied in the direction of loom, weaving, textile and papermaking, etc., and can solve the problems of detection value change and change increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

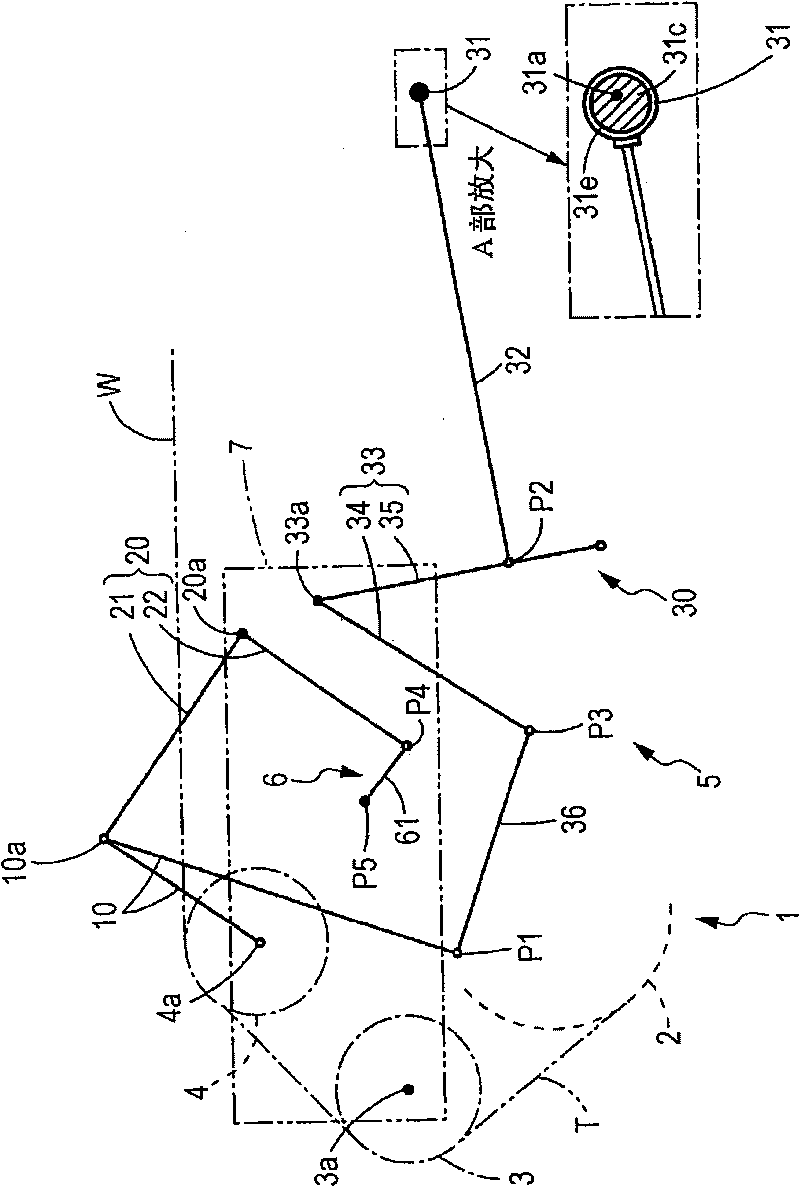

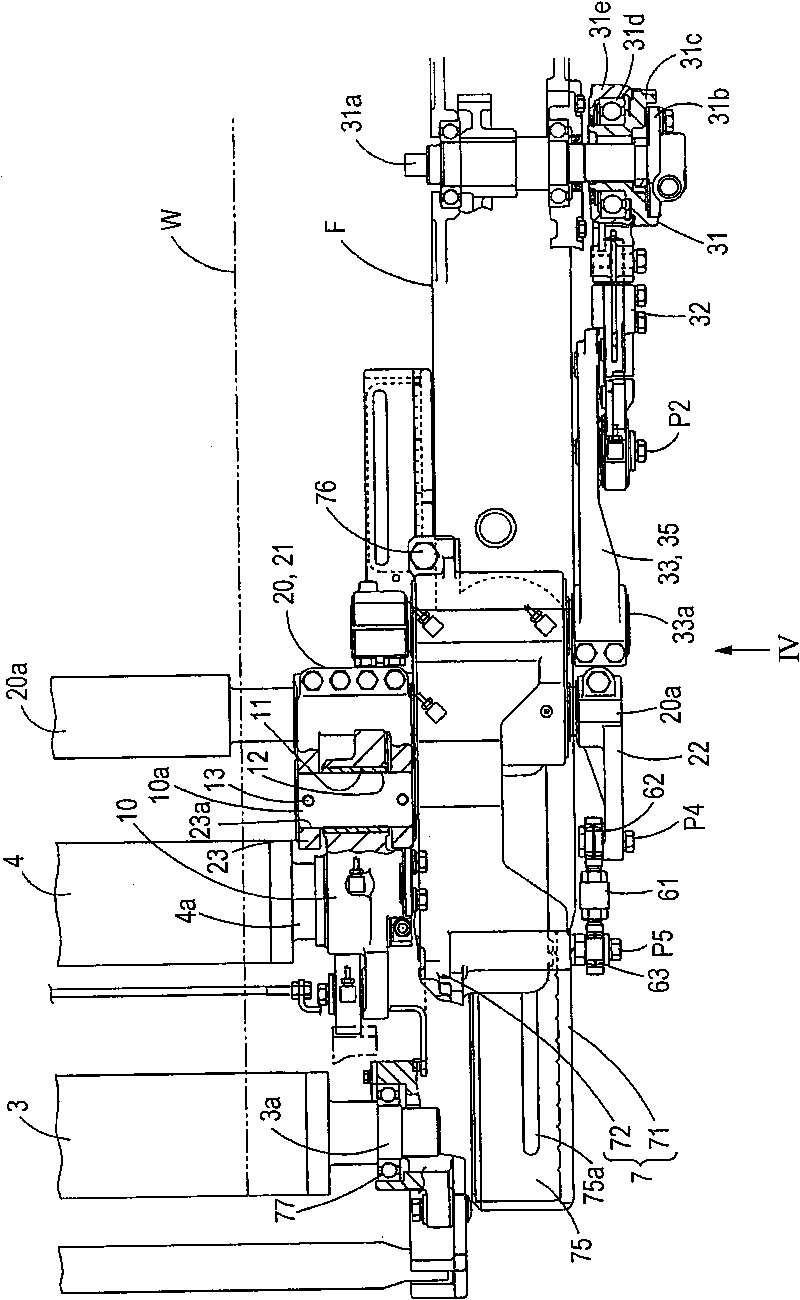

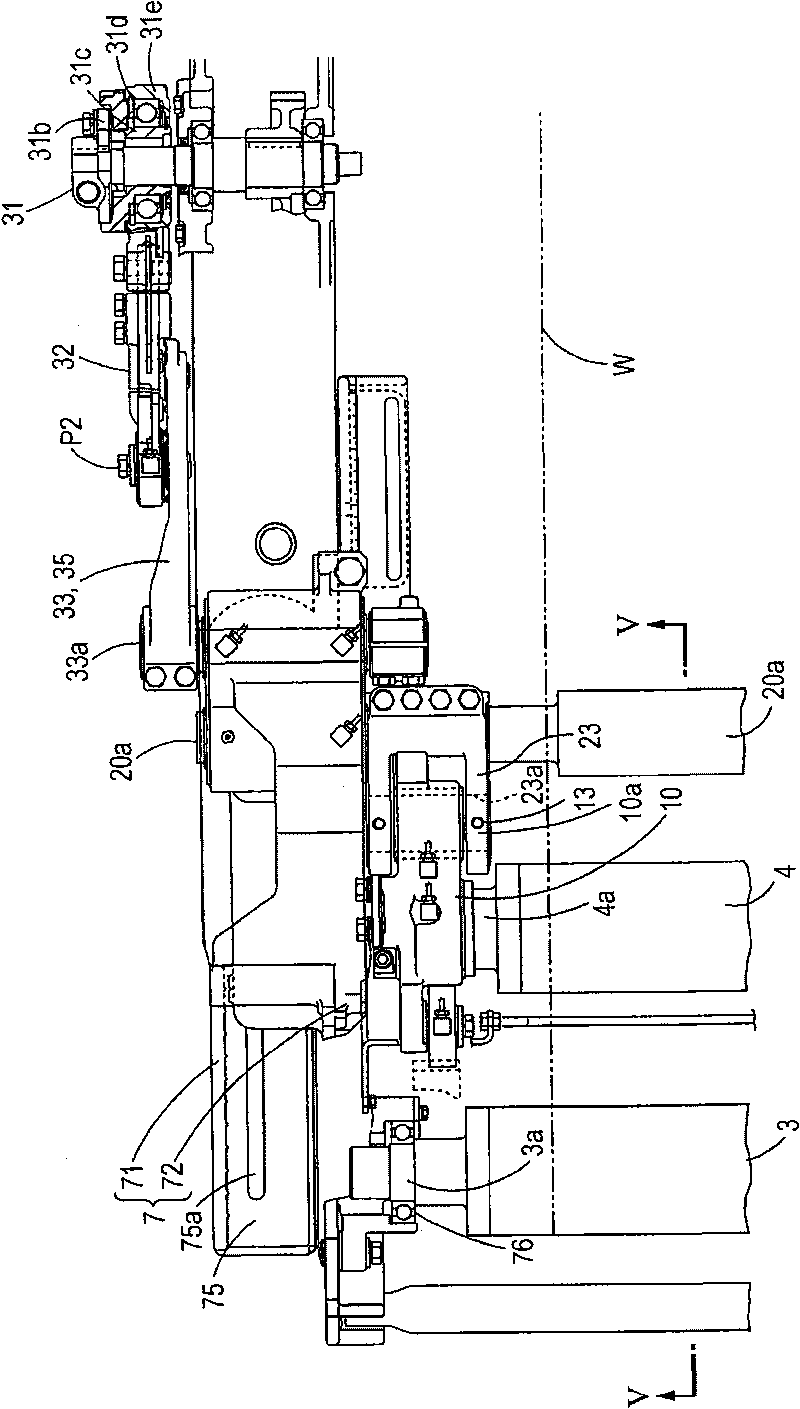

[0046] according to Figure 1 to Figure 5 An example of the let-off device 1 of the loom using the positive easing mechanism 5 will be described. In the following description, the "front-rear direction" refers to the moving direction of the warp yarn according to feeding of the warp yarn. In addition, the take-up device side in the warp direction of the loom is referred to as "front side", and the let-off device 1 side is referred to as "rear side". figure 1 It is an explanatory diagram of the active easing mechanism 5 in the let-off device 1 of the above-mentioned loom. The black dots in the figure are the fulcrums directly or indirectly fixed on the rack. The white dots in the diagram are pivots that are not fixed to the rack. figure 2 It is a plan view of the warp let-off device 1 of the loom, and shows the right side part seen from the rear side. image 3 It is a plan view of the let-off device 1 of the loom, and shows the left side part seen from the rear side. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com