Rotary braiding machine

A technology for knitting machines and yarn carrying discs, which is applied in the field of knitting machines, can solve problems such as reduced work efficiency, high cost, and complex control systems, and achieve the effects of improving work efficiency and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

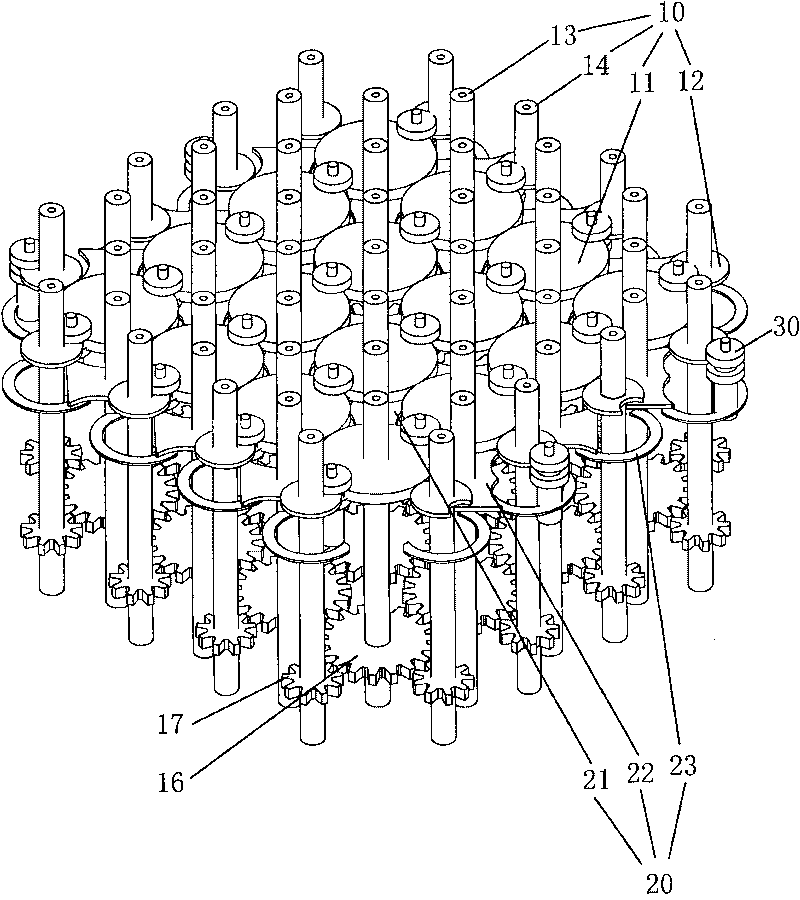

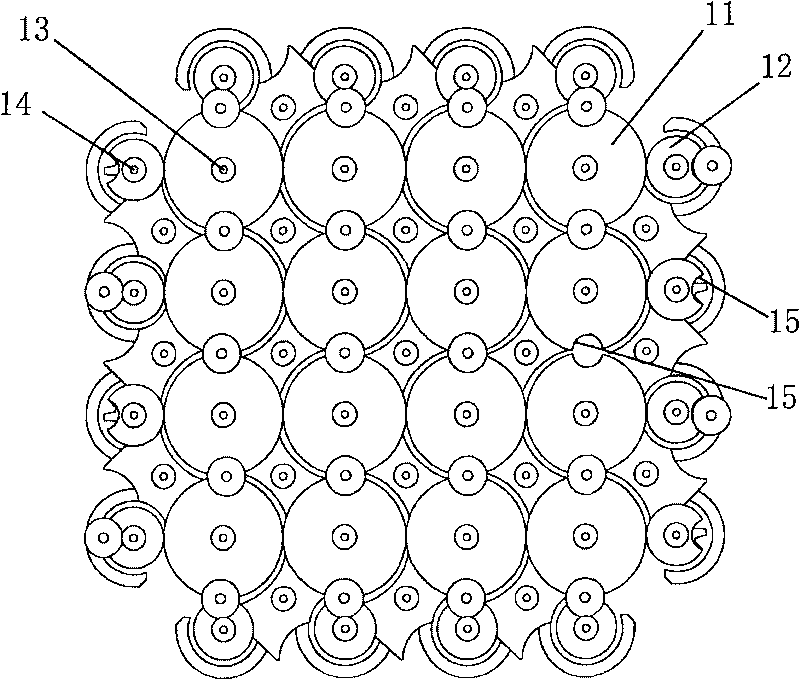

[0050] Such as figure 2 Shown is a schematic perspective view of a preferred embodiment of the rotary knitting machine. It can be seen from the figure that it includes a drive assembly 10, a reversing assembly 20, and a yarn carrying seat 30. The drive assembly 10 includes a determinant arrangement And the yarn carrying discs 11 and 12 that rotate synchronously, the center of the yarn carrying disc 11 can be used for axial yarn (not shown in the figure) to pass through, and the yarn carrying seat 30 is connected with the spindle (not shown in the figure) of the weaving yarn, And it advances under the drive of the yarn-carrying discs 11, 12, and the reversing assembly 20 is arranged on the advancing path of the yarn-carrying seat 30, and continuously adjusts the advancing direction of the yarn-carrying seat 30. The structure of each part will be discussed in detail below.

[0051] combine figure 2 , image 3 As shown, the drive assembly 10 includes an inner yarn-carrying d...

Embodiment 2

[0058] In this embodiment, the knitting path of the yarn-carrying seat 30 is designed as a straight line, which basically adopts all the components and movement methods in Embodiment 1, the difference is that the movable baffle includes an inner baffle 41 and an outer baffle Plate 42, at least two track edges formed on the inner baffle 41 and the outer baffle 42 are linear track grooves, and the combination of the linear track grooves forms the linear motion track of the yarn carrying seat, and the fixed baffle is The fixed track is an arc-shaped track groove formed on the fixed baffle. Specifically:

[0059] Such as Figure 11A , Figure 11B , Figure 11C As shown, the two concave arcs 24 of the inner baffle 41 are changed into the form of two linear track grooves 44, and in order to prevent each inner baffle 41 from interfering when rotating, two opposite sides of the inner baffle 41 are Designed with slope 411 (attached Figure 11C shown). In addition, in order to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com