Environmentally-friendly, energy-saving and emission-reducing power machine

An environmental protection, energy-saving, power machine technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve problems such as oil leakage, achieve good sealing, improve work efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

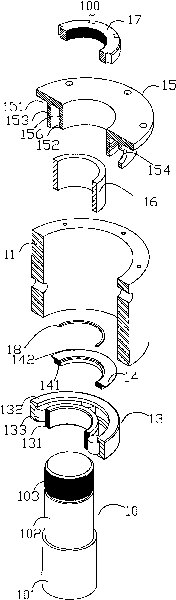

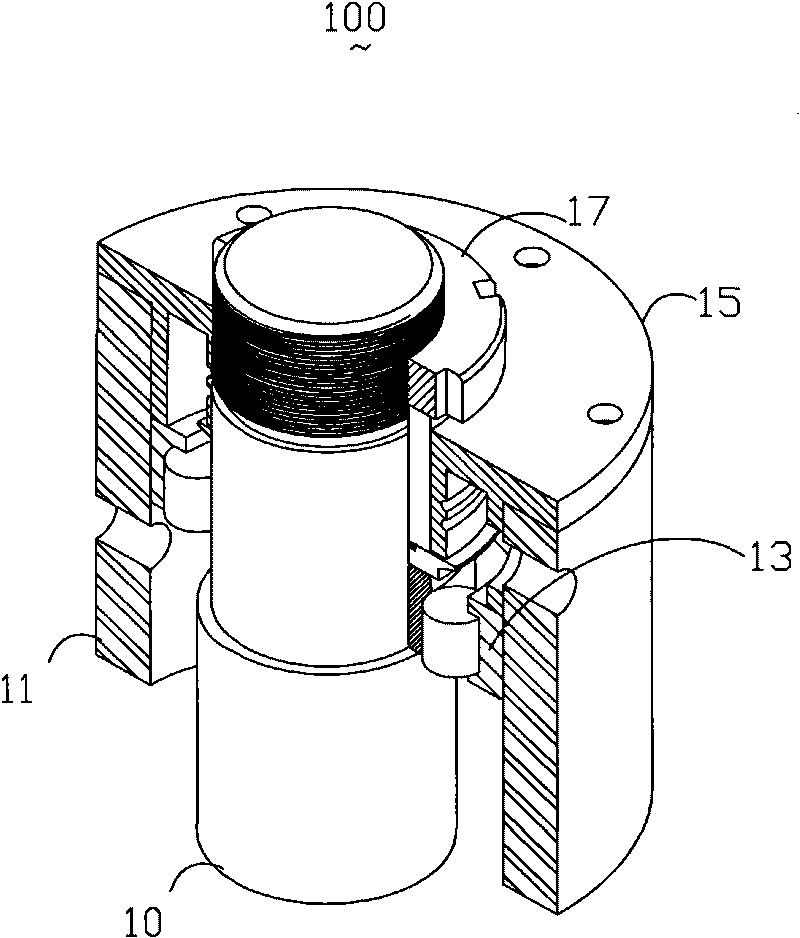

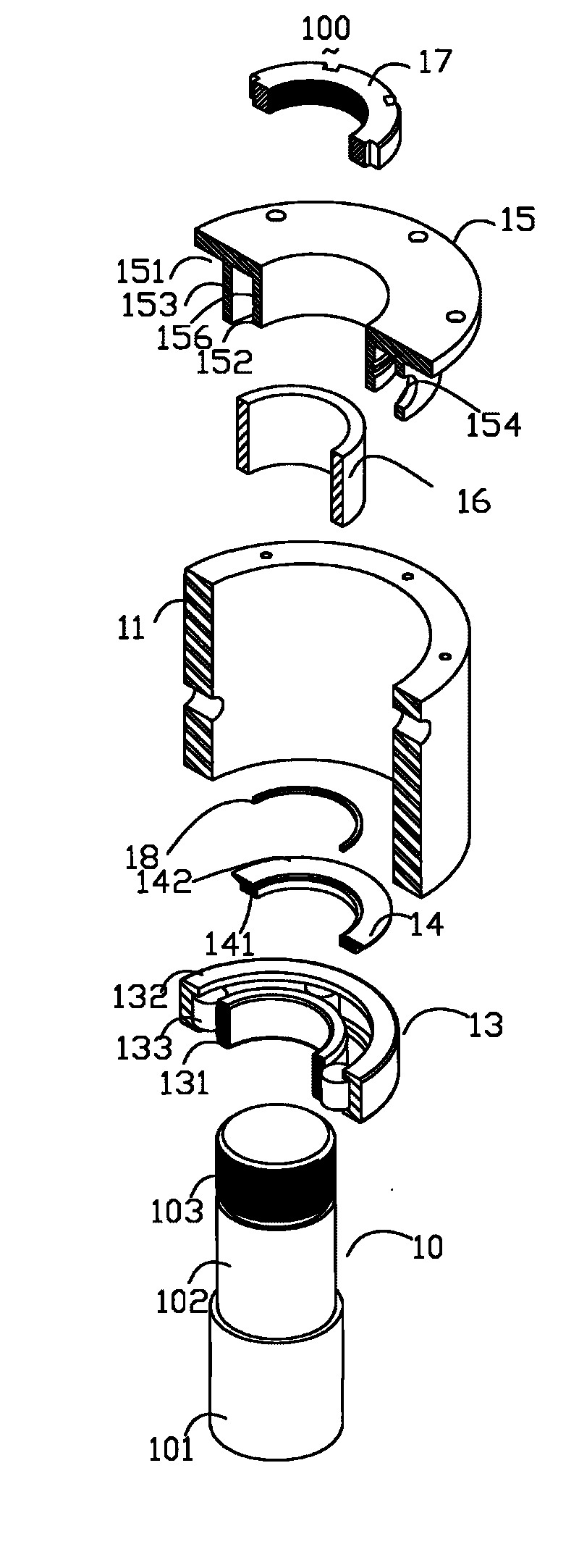

[0009] see figure 1 , figure 1 It is a three-dimensional exploded schematic diagram of an environment-friendly, energy-saving and emission-reducing power machine of the present invention. The environment-friendly, energy-saving and emission-reducing power machine 100 is an environment-friendly, energy-saving and emission-reducing power machine that converts heat sources such as industrial waste steam and waste liquid into power by using female and male screws. It includes a front shell (not shown), a bearing seat 11, a shaft 10, a bearing 13 and a non-contact sealing structure (not marked). The front shell accommodates the bearing seat 11 , the shaft 10 , the bearing 13 and the non-contact sealing structure. The bearing seat 11 is a hollow cylinder, which is rotatably connected with the shaft 10 via the bearing 13 . The non-contact sealing structure seals the shaft 10 to ensure that the shaft 10 does not leak oil when running at high speed.

[0010] The shaft 10 is a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com