Four-point contact ball bearing

A four-point contact and ball bearing technology, applied in the field of bearings, can solve problems such as inability to bear axial loads, reduced service life of bearings, and large load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

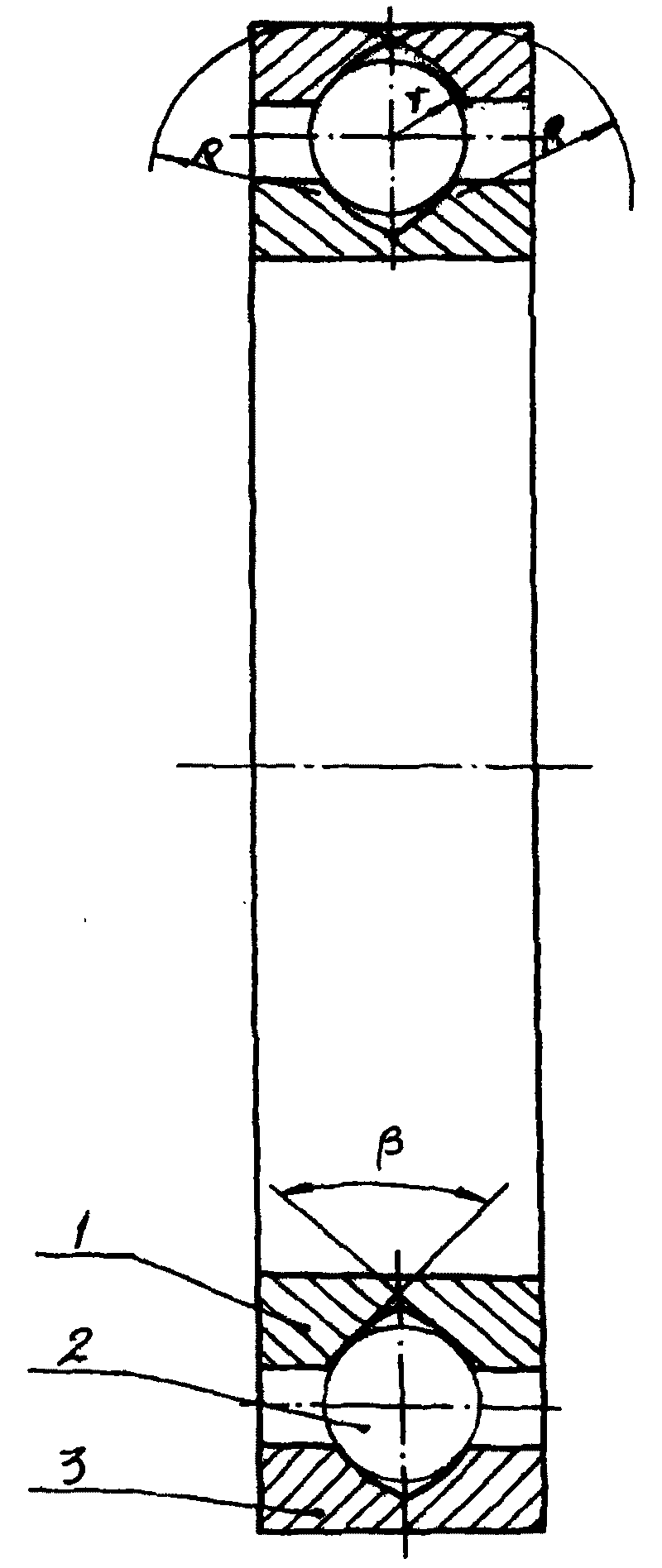

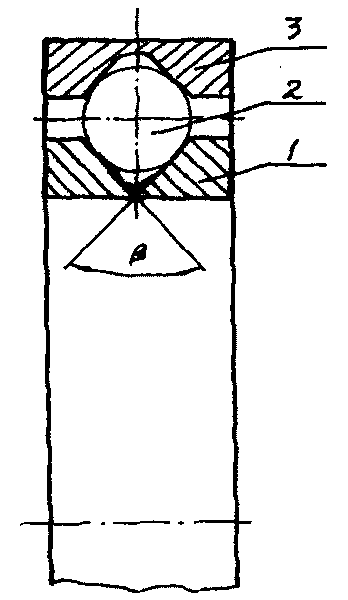

[0013] The four-point contact ball bearing of the present invention comprises a bearing inner ring 1, a ball 2 and a bearing outer ring 3, the ball 2 is arranged between the bearing inner ring 1 and the bearing outer ring 3, and between the bearing inner ring 1 and the bearing outer ring 3 There are ring-shaped raceways on both sides. The cross-sectional shape of the ring-shaped raceway on the inner ring of the bearing is symmetrical to that of the ring-shaped raceway on the outer ring of the bearing. Each raceway has two points of contact with each ball. And the angle β between the two contact points and the connecting line of the center of the ball is any value in 30°-120°. In this example, β is 90°. The cross-sectional shape of the annular raceway is symmetrical to the ball For the two arcs of the axis, the relationship between the radius R of the arc and the radius r of the ball is R=2.1r.

[0014] Of course, the cross-sectional shape of the annular raceway can also be des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com