Four-way mix-proof double-seat valve

A double-seat valve, mix-proof technology, applied in multi-port valves, valve details, valve devices, etc., can solve problems such as liquid pollution and reaction, and achieve the effect of ensuring product quality and production, and simplifying the action process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

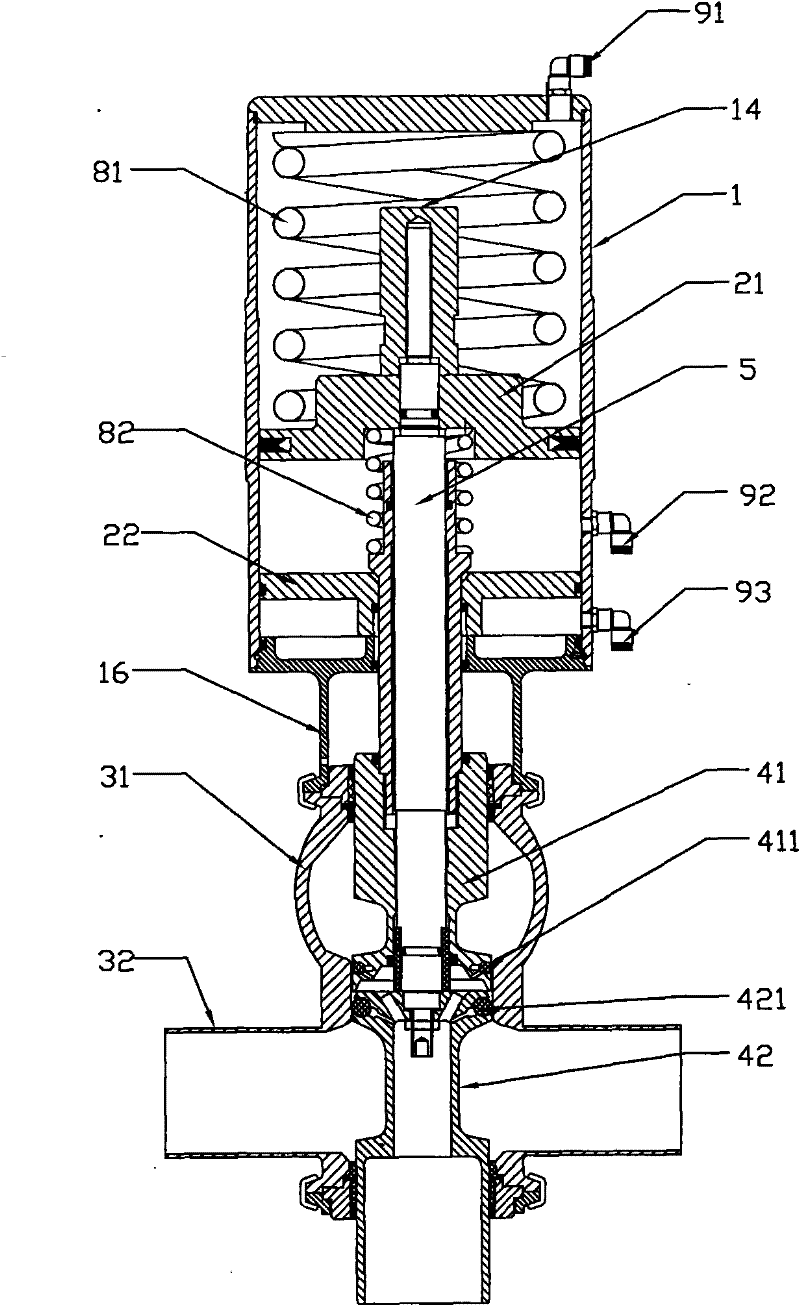

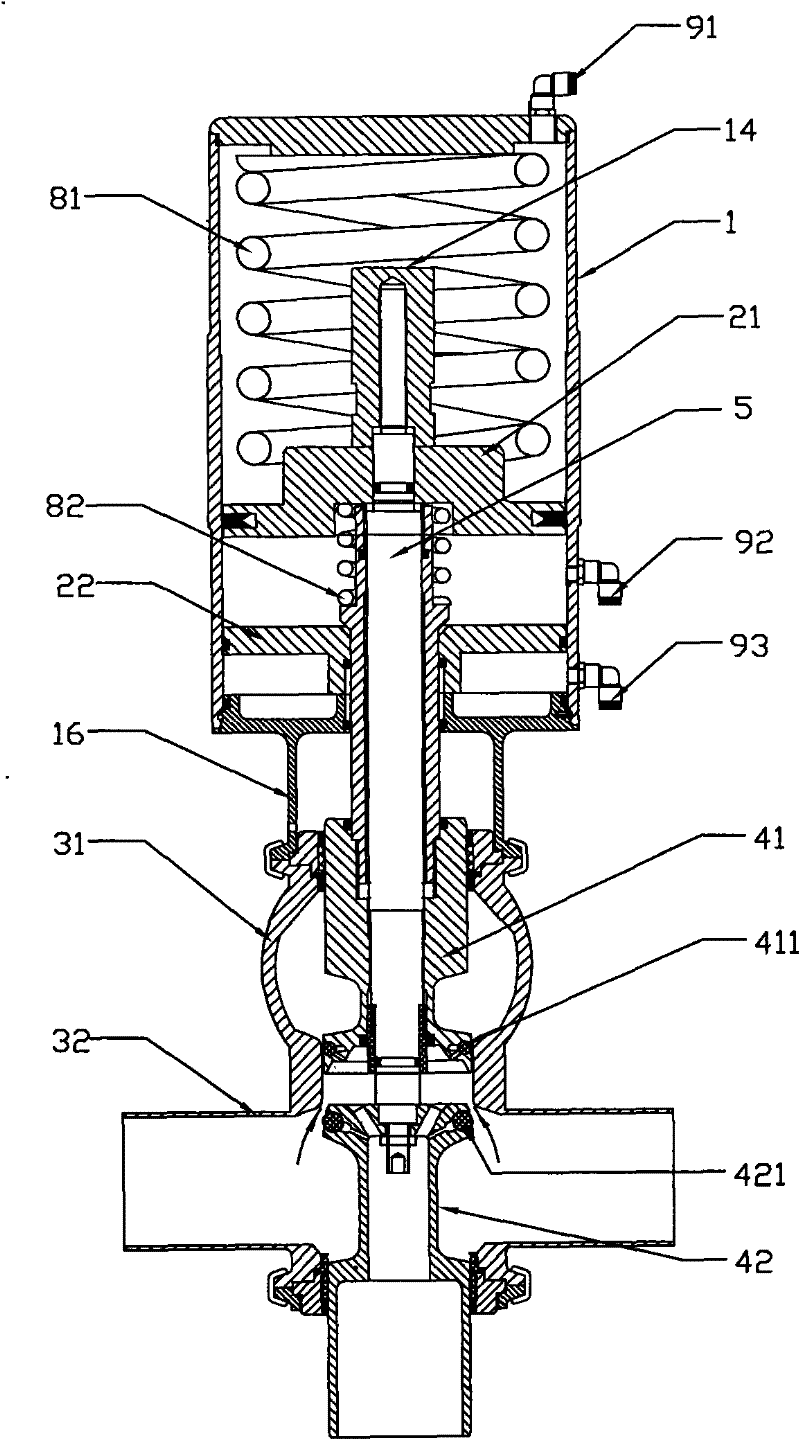

[0046] The four-way anti-mixing double-seat valve of the present invention includes a cylinder body 1 and an upper piston 21 provided with a limit end 14 in the cylinder body 1 for resetting the first biasing component of the upper piston 21; The top end of the cylinder 1 above the upper piston 21 is provided with a first power medium inlet and outlet, and the cylinder 1 below the upper piston 21 is provided with a second power medium inlet and outlet; a valve located at the lower part of the cylinder 1 The valve body is divided into an upper valve body 31 and a lower valve body 32; one end is connected to the upper piston 21, and the other end penetrates the bottom end of the cylinder 1 and extends to the shaft core 5 in the valve body;

[0047] It also includes an upper valve core 41 that seals the upper valve body 31 and a lower valve core 42 that seals the lower valve body 32; in the cylinder 1 located on the lower side of the upper piston 21, there is a contact with the shaft...

Embodiment 2

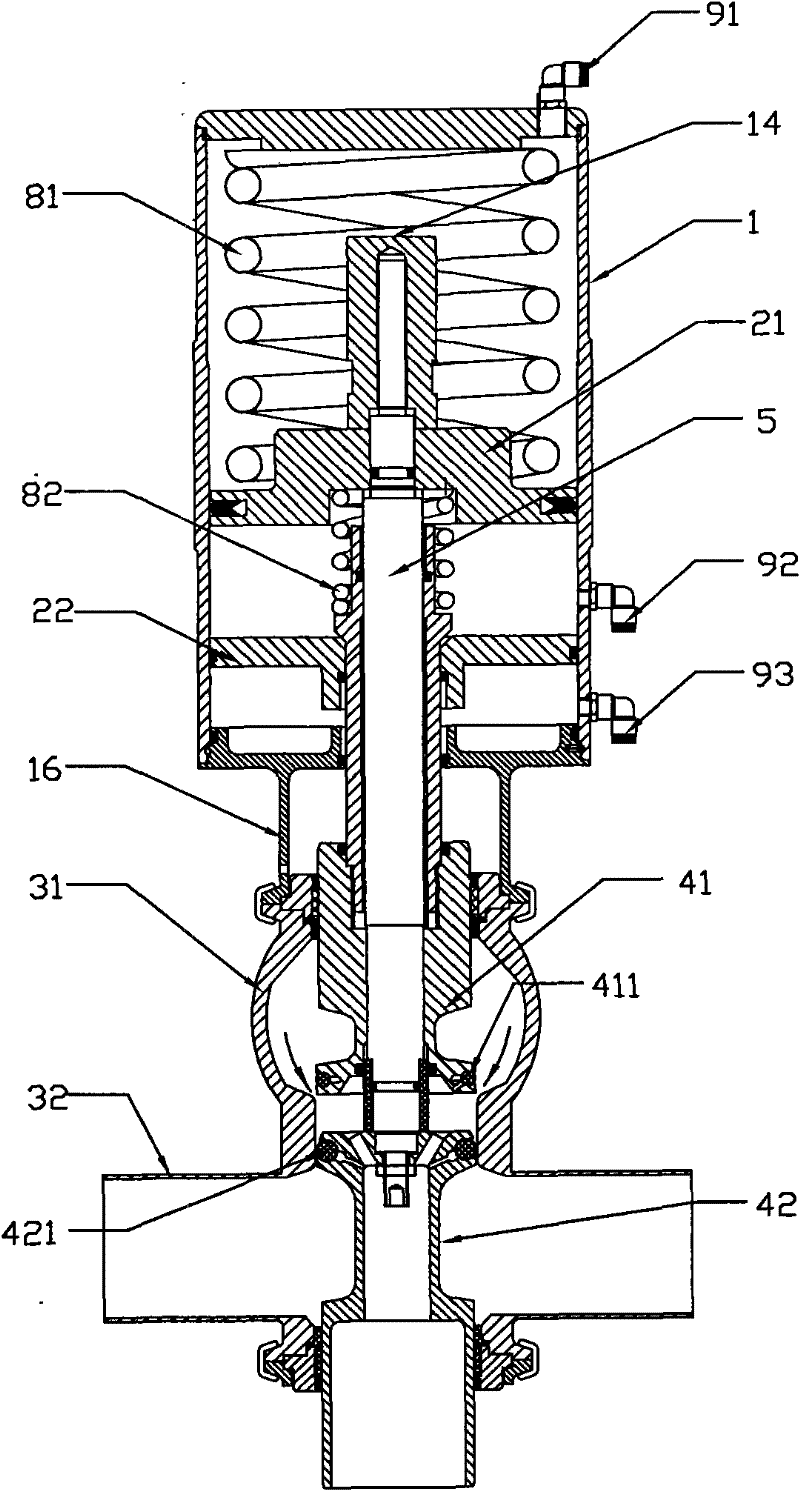

[0061] The four-way anti-mixing double-seat valve described in this embodiment includes a cylinder block 1 and an upper piston 21 with a limit end 14 in the cylinder block 1 for resetting the first biasing component of the upper piston 21 Between the first biasing component and the upper piston 21 is provided with a spring limit device hooked on the cylinder 1, the spring limit device in this embodiment is set as a limit plate 7, the The cylinder 1 is provided with a protrusion for hooking the spring limit device;

[0062] A first power medium inlet and outlet are provided on the top of the cylinder 1 above the upper piston 21, and a second power medium inlet and outlet are provided on the cylinder 1 below the upper piston 21; The valve body is divided into an upper valve body 31 and a lower valve body 32; one end is connected to the upper piston 21, and the other end penetrates the bottom end of the cylinder 1 and extends to the shaft core 5 in the valve body; It includes an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com