High-utilization-ratio and high-uniformity LED illumination system used in direct-write photoetching machine

A technology of LED lighting and utilization rate, applied in the field of LED lighting system, can solve problems such as low light source utilization rate, difficult debugging and maintenance, complex structure, etc., achieve good light uniformity, reduce complexity, design difficulty, and high luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and specific embodiments.

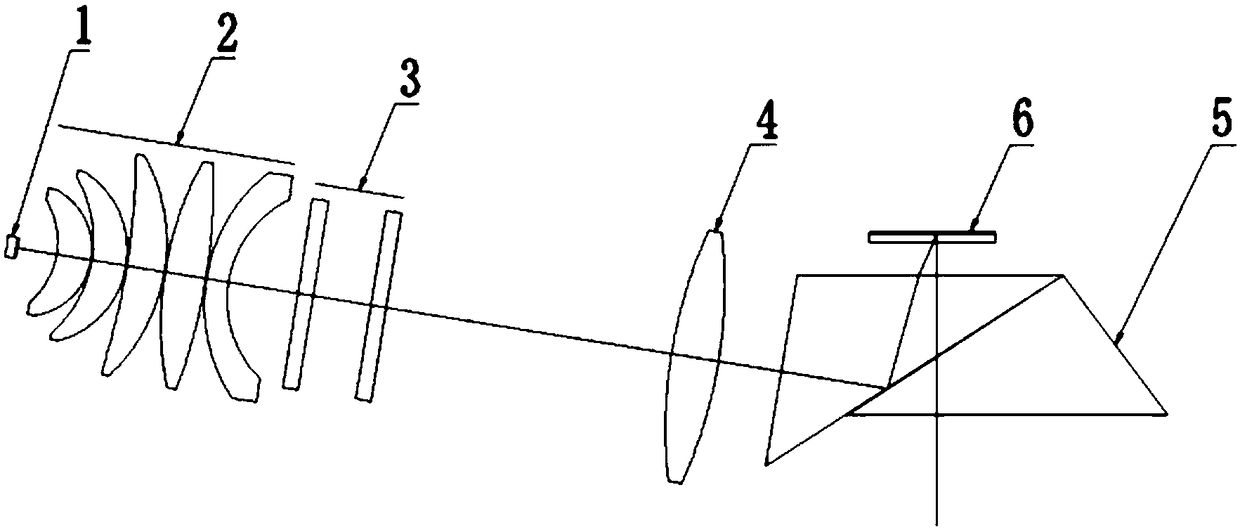

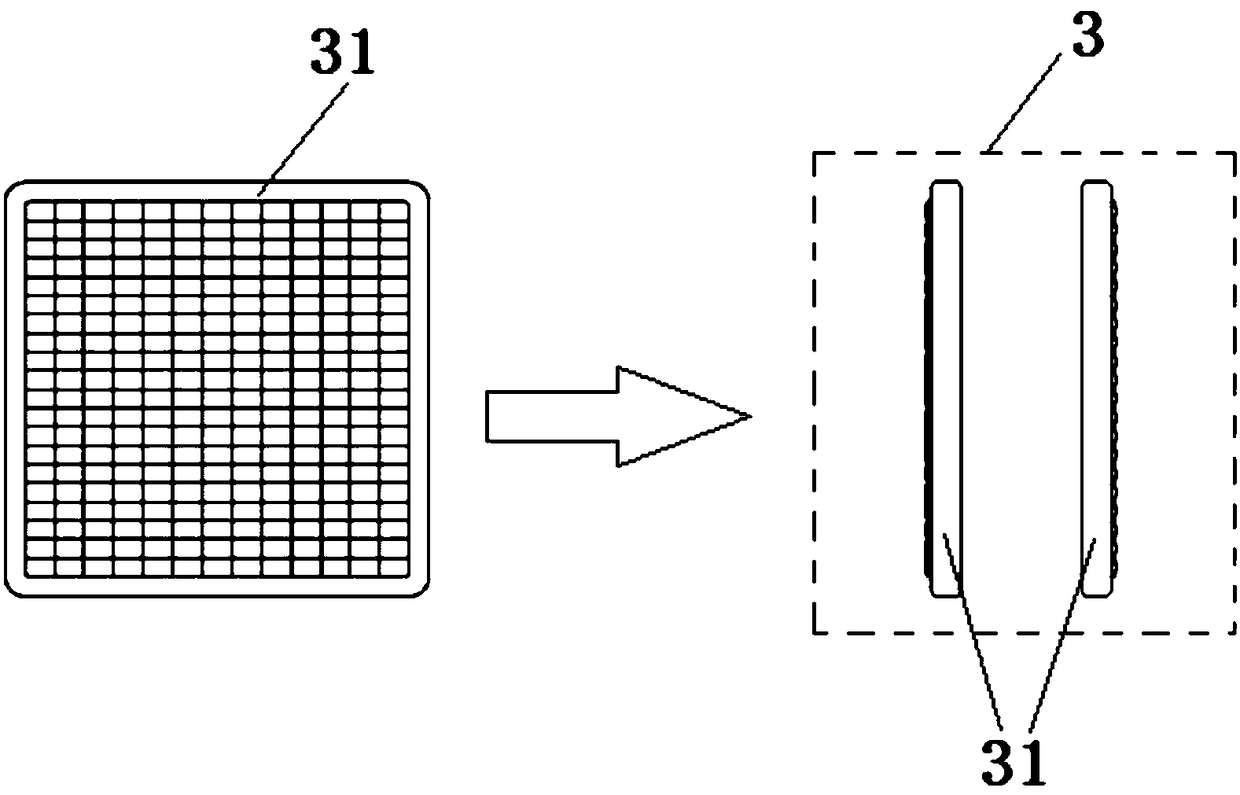

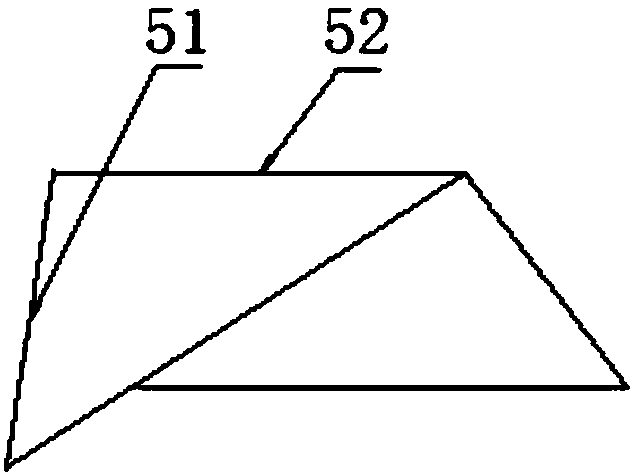

[0027] Such as figure 1 As shown, an LED lighting system with high utilization and high uniformity in a direct writing lithography machine includes an LED light source 1, a collimator lens group 2, a homogenizing lens group 3, a condenser lens 4, and a turning prism 5. The centers of the LED light source 1, the collimator lens group 2, the homogenizing lens group 3 and the condenser lens 4 are all located on the same axis, and the turning prism 5 is located under the DMD digital mask 6. The numerical aperture corresponding to the divergence angle of the emitted light of the LED light source 1 is NA 0.85, and this super large numerical aperture is adopted to achieve high utilization of the illumination system. The LED light source 1 can be a single LED lamp bead or an array of multiple LED lamp beads. Such as figure 2 As shown, the homogenization lens group 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com