Piston for an internal combustion engine

A technology for internal combustion engines and pistons, which is applied to pistons, mechanical equipment, engine components, etc., and can solve problems such as loss of anti-corrosion effect, wear of the protective layer, and corrosiveness of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

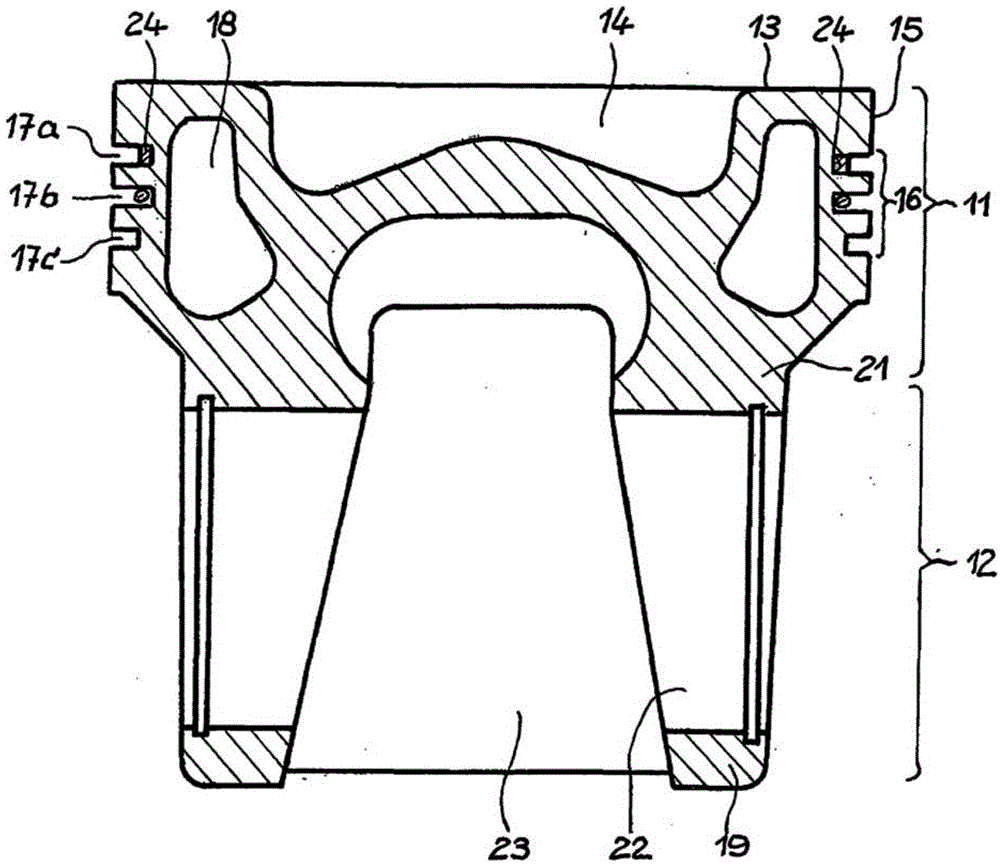

[0018] figure 1 An embodiment of the piston 10 of the invention is shown. In an embodiment, the piston 10 is a one-piece box piston and has a piston head 11 and a piston skirt 12 . The piston 10 can be produced, for example, from a material based on cast iron or steel. Of course, the piston according to the invention can also be configured as a compound piston.

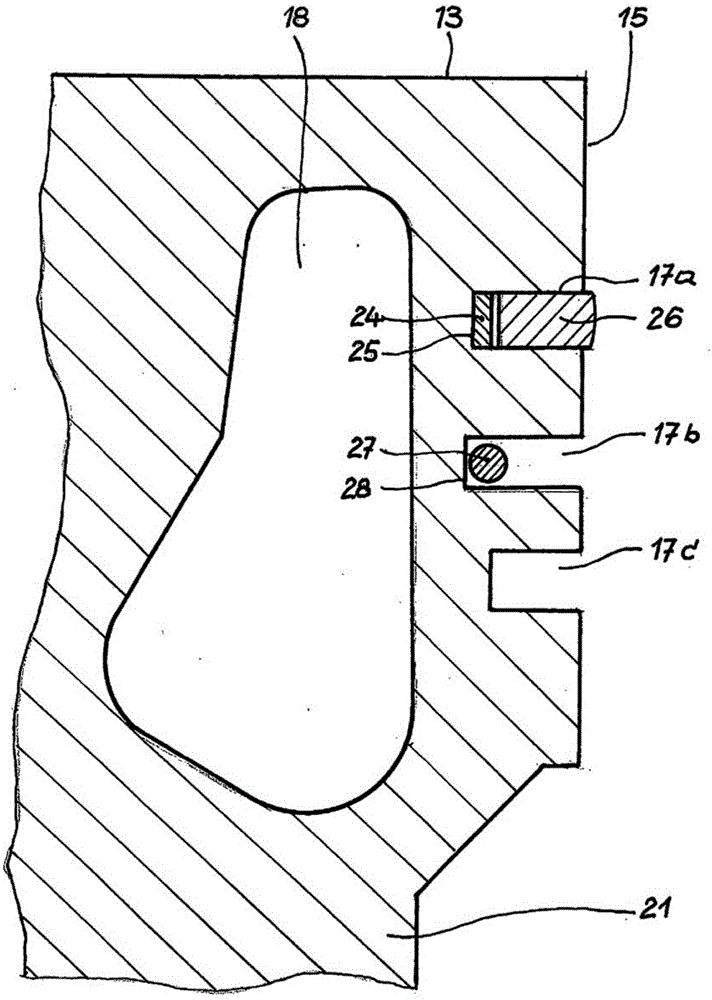

[0019] The piston head 11 has a piston crown 13 containing a combustion chamber 14, a surrounding land 15 and a surrounding ring groove portion 16 containing ring grooves 17a, 17b, 17c for receiving piston rings. Furthermore, a closed, circumferential cooling channel 18 is formed between the combustion chamber 14 and the annular groove part 16 .

[0020] The piston skirt 12 has hubs 19 in a known manner, which are connected to the underside of the piston head 11 by means of hub connections 21 . The hub 19 is provided with a hub hole 22 for receiving a piston pin (not shown). The hubs 18 are connected to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com