Transmission line self-sealing wire pulley

A transmission line and self-sealing technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of aging and poor sealing effects of components, and achieve the effect of improving the safety factor of operations, improving work efficiency, and improving the anti-off rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

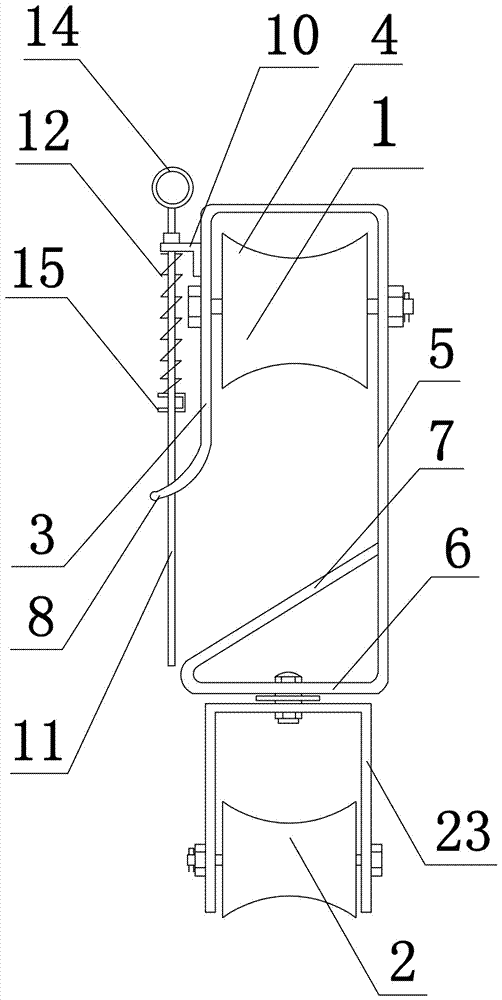

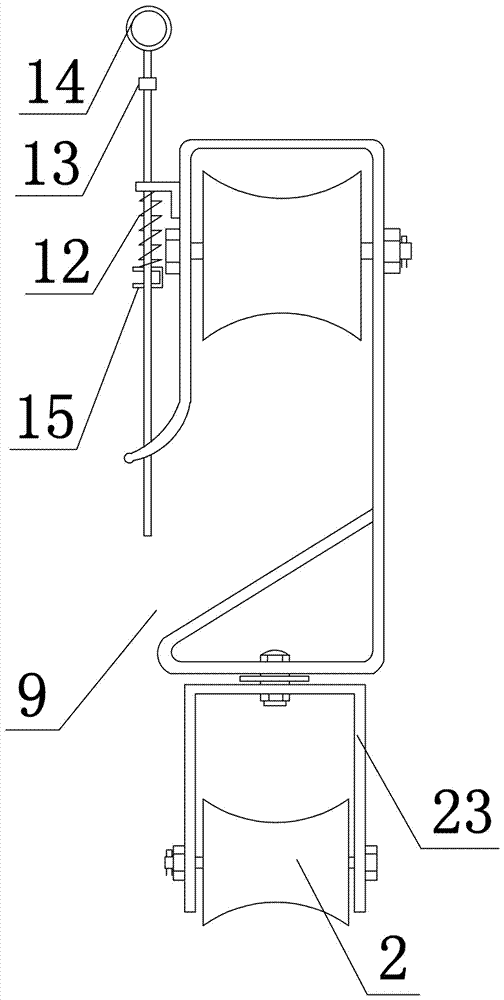

[0028] Such as figure 1 and figure 2 As shown, the present invention comprises a tackle body and a self-sealing device. The tackle body includes a hook and a base 23. A wire pulley 1 is installed in the hook, and a transfer pulley 2 is installed in the base. The hook includes a vertical plate-3 and a horizontal plate-connected in sequence 4, vertical plate two 5, horizontal plate two 6 and inclined plate 7, the length of vertical plate one 3 is less than the length of vertical plate two 5, vertical plate one 3 lower ends are provided with arc plate 8, arc plate 8 and The gap between the horizontal plate two 6 is the opening 9 of the hook, and the vertical plate one 3 outsides are provided with a spacer plate 10, and the spacer plate 10 offers a vertical through hole; the self-sealing device includes a pull bar 11, a spring 12 and Pull rod limit block 13, pull ring 14 is set on the top of pull rod 11, limit pin 15 is set on pull rod 11, spring 12 is sleeved on the outer surfa...

Embodiment 2

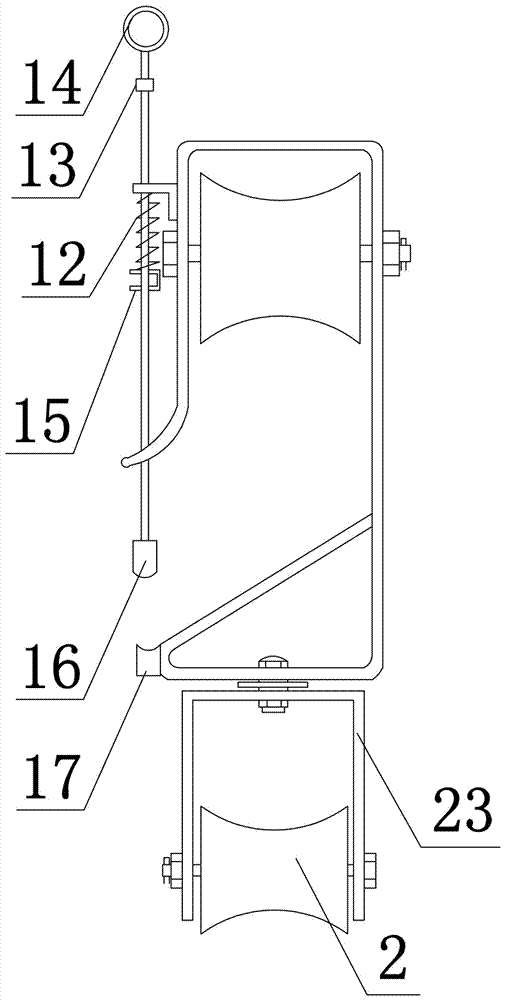

[0031] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as image 3As shown, a magnet one 17 is arranged between the inclined plate 7 and the horizontal plate two 6, and the lower end of the pull rod 11 is fixedly connected to the magnet two 16 which is attracted to each other by the magnet one 16. The lower end of the magnet one 17 is an arc groove structure, and the upper end of the magnet two 16 is It is an arc-shaped convex structure cooperating with magnet one 17. The suction force F1 when magnet one 17 and magnet two 16 are in contact is greater than the maximum elastic force F2 of spring 12, and the suction force F1 when magnet one 17 and magnet two 16 are in contact is smaller than this. Invent the self-weight G of the whole.

[0032] In this embodiment, the mutual attraction between the magnet one 17 set between the inclined plate 7 and the horizontal plate two 6 and the magnet two 16 set at the lower end of the pull r...

Embodiment 3

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 4 As shown, the transmission pulley 2 includes a transmission pulley one 18 and a transmission pulley two 19 arranged up and down, the two side edges of the transmission pulley one 18 are provided with a tooth one 20, and the two side edges of the transmission pulley two 19 are provided with teeth matched with the tooth one 20. Two 21.

[0035] In this implementation, the lower end of the first transmission pulley 18 is geared with the upper end of the second transmission pulley 19. Through the principle of synchronous rotation of the double pulleys, the traction rope that pulls the transmission pulley 2 is clamped between the first transmission pulley 18 and the second transmission pulley 19 during use. In between, the side slipping problem of the traction rope can be effectively prevented, that is, the first transmission pulley 18 and the second transmission p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com