Hang-up mechanism for hang-up table

A yoke and guide shaft technology, used in measuring devices, instruments, measuring instrument components, etc., can solve the problems of low sudden stop dynamic index, sudden stop start time lag, etc., and achieve short damping oscillation period and low adjacent amplitude ratio. , the effect of fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

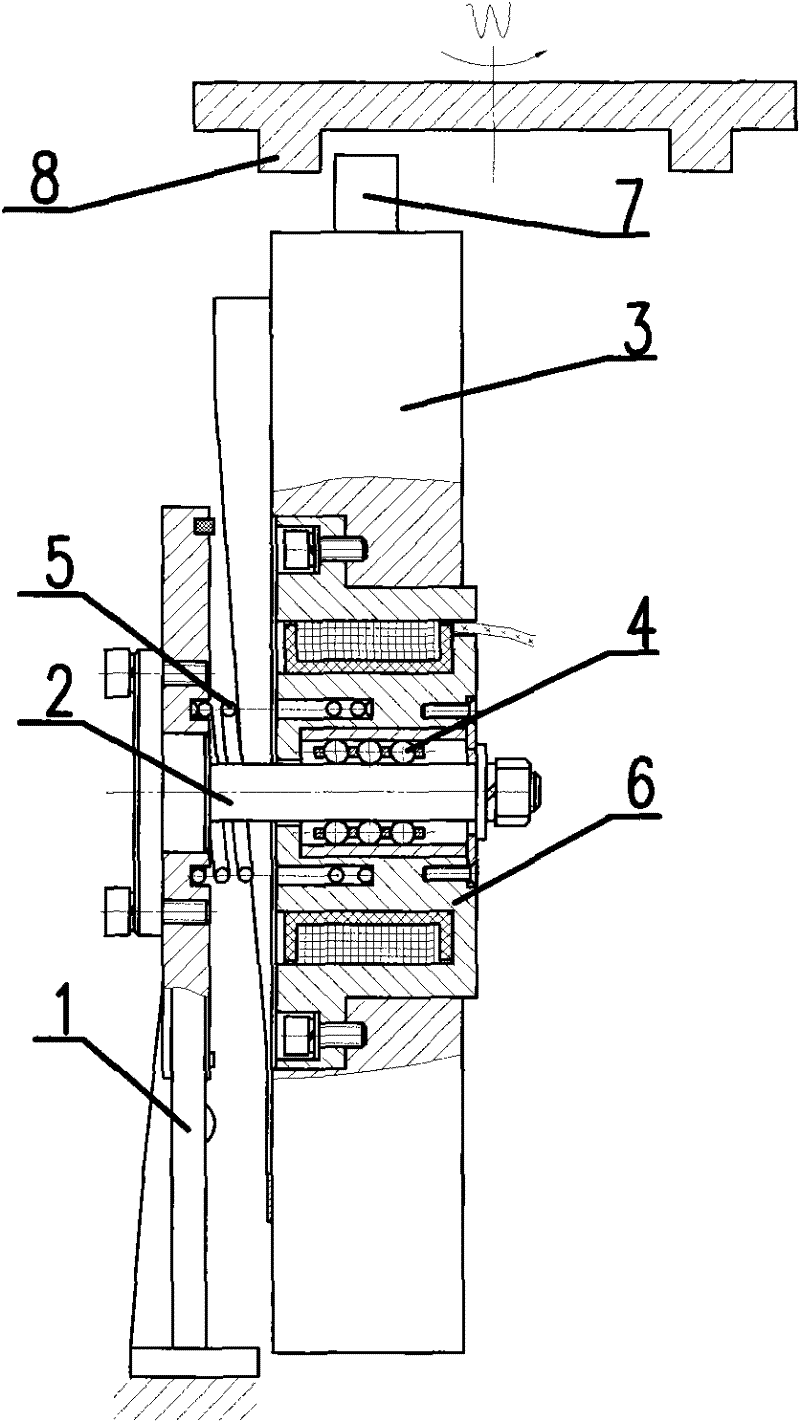

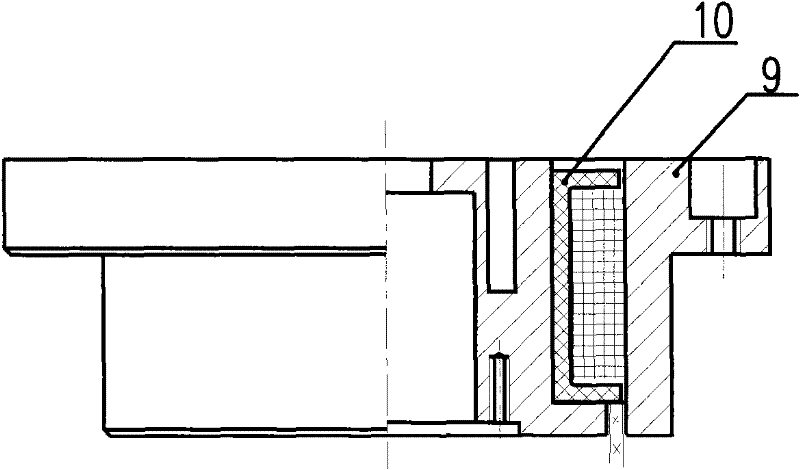

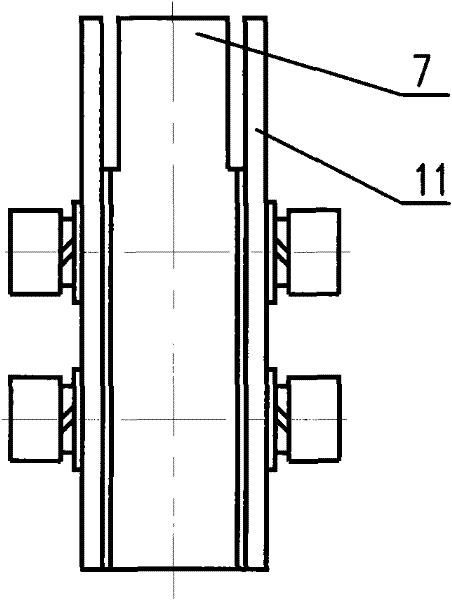

[0012] like figure 1 Shown is the sudden stop mechanism of the present invention, i.e. the basic form of the present invention, consisting of a support 1, a guide shaft 2, an inertia ring 3, a bearing 4, a cylindrical spring 5, a yoke 6, and a retaining pin 7. The bracket 1 equipped with the armature is fixed on the base of the sudden stop platform, the guide shaft 2 is installed on the bracket 1, the inertia ring 3 is installed on the outside of the yoke 6, the yoke 6 is installed on the guide shaft 2 through the bearing 4, and the bracket 1 Both the armature and the yoke 6 have grooves for installing the cylindrical spring 5, and the cylindrical spring 5 keeps the yoke 6 at a certain distance from the armature on the bracket 1 in a free state, that is, the inertia ring 3 keeps a certain distance from the bracket 1 , the stop pin 7 is installed on the inertia ring 3. When the sudden stop platform needs to stop suddenly, the yoke iron 6 is energized while the sudden stop platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com