Camera module, electronic device including the same, and method for positioning lenses of camera module

A positioning method and camera technology, which is applied to the camera body, TV, camera, etc., can solve the problems of large thrust and spring deformation, and achieve high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

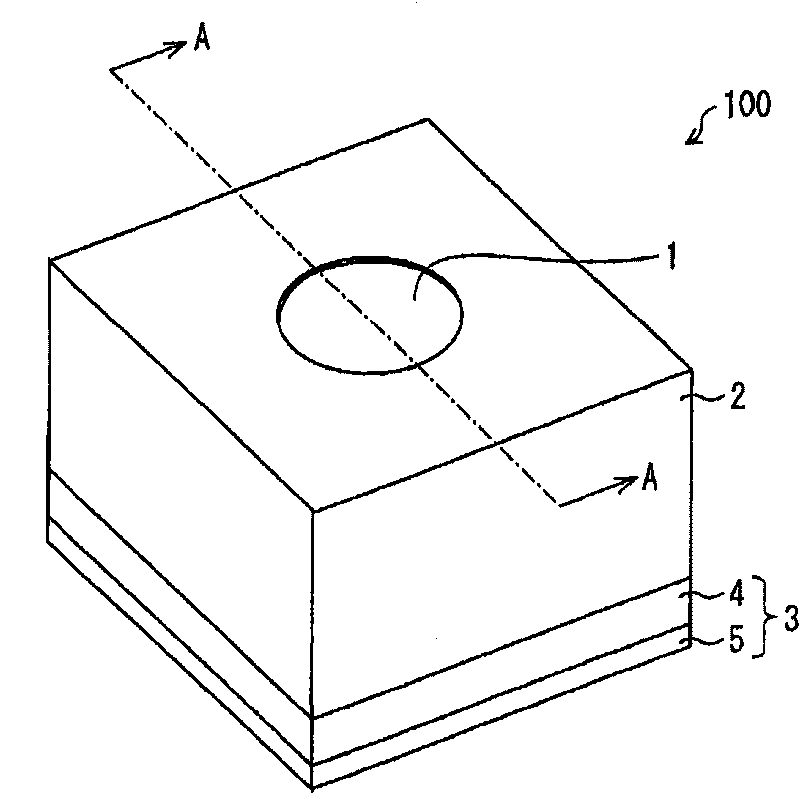

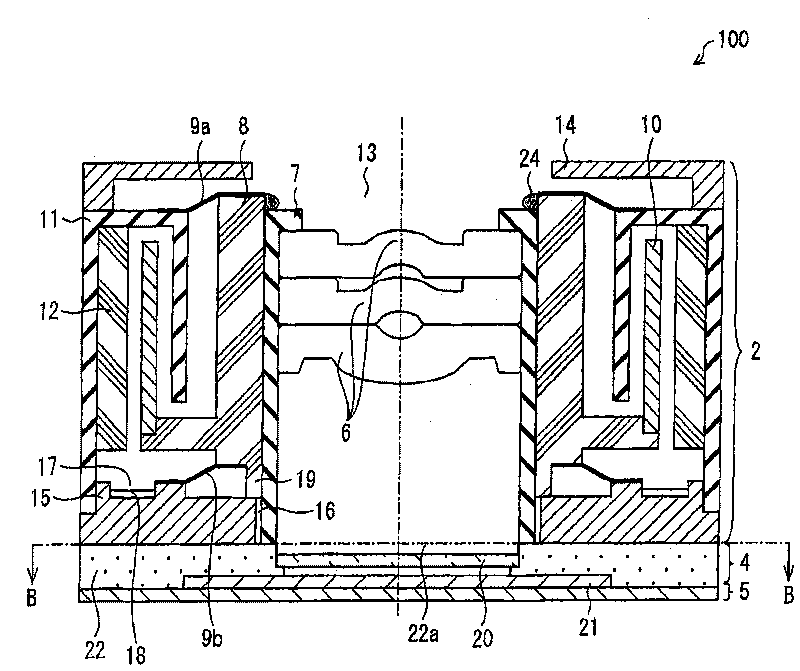

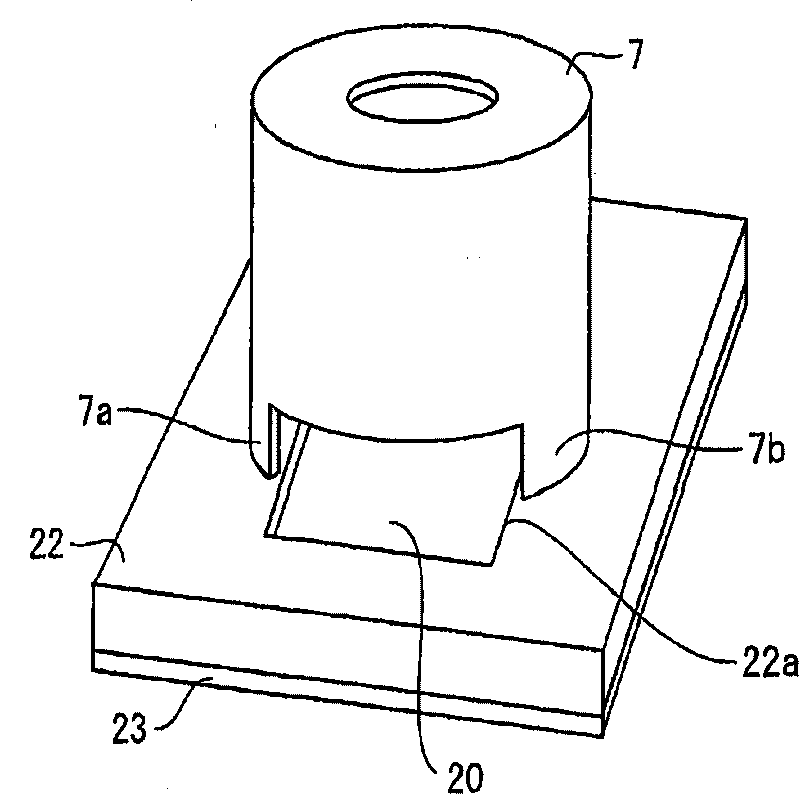

[0082] Below, based on Figure 1 to Figure 14 , Figure 16 ~ Figure 20 Embodiments of the present invention will be described.

[0083] figure 1 It is a perspective view of the camera module of this embodiment. The camera module 100 includes: an optical unit 1 as an imaging optical system; a lens driving device (lens driving unit) 2 that drives the optical unit 1 ; and an imaging unit 3 that photoelectrically converts light passing through the optical unit 1 . The optical unit 1 is held inside the lens driving device 2 . The imaging unit 3 is configured to include a sensor unit 4 and a substrate 5 on which the sensor unit 4 is mounted. The camera module 100 is configured by laminating the sensor unit 4 and the lens driving device 2 sequentially in the optical axis direction on the substrate 5 . In the following description, for convenience, the side of the optical unit 1 is referred to as the upper side, and the side of the imaging unit 3 is referred to as the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com