Light-emitting diode

A technology of light-emitting diodes and light-emitting surfaces, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problem of uneven light output of light-emitting diodes, and achieve the effect of reducing the total reflection effect and increasing the light extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

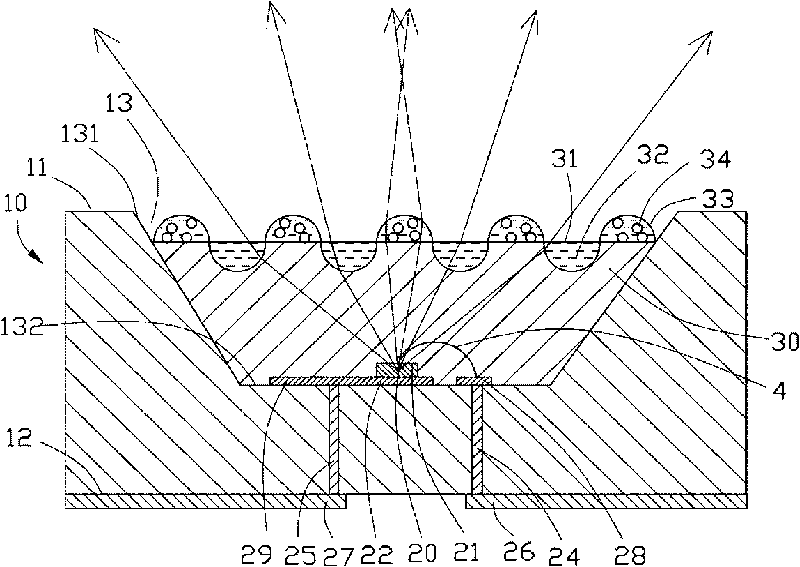

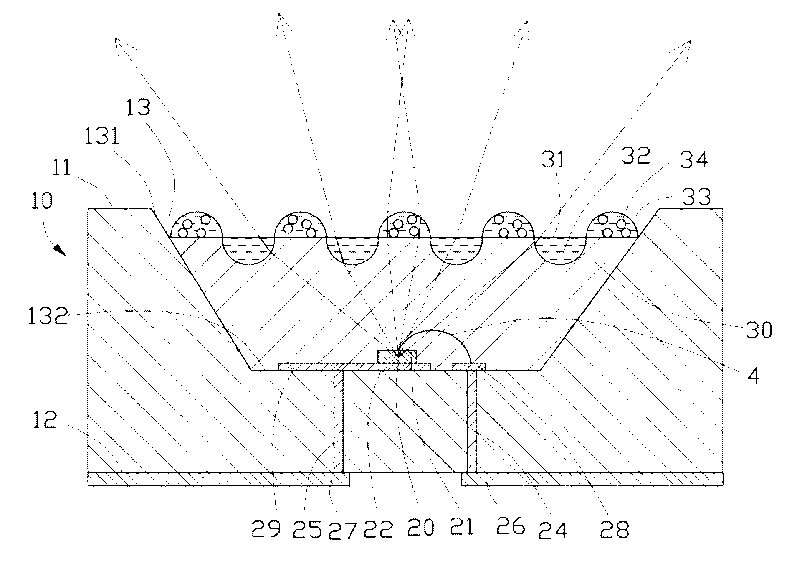

[0007] Such as figure 1 As shown, the light emitting diode includes a base 10 , a light emitting diode die 20 and a first package body 30 . The base 10 includes an upper surface 11 and a lower surface 12 opposite to each other. A blind hole 13 is defined in the center of the base 10 , an inner wall 131 is formed around the periphery of the blind hole 13 , and a bottom surface 132 is formed at the bottom of the blind hole 13 . The blind hole 13 provides accommodating space for the light-emitting diode die 20 and the first package body 30, which is wide at the top and narrow at the bottom. The inner wall surface 131 of the base 10 is inclined radially inward from the upper surface 11 to the bottom surface 132, The first conductive column 24 and the second conductive column 25 spaced apart from each other are opened downwards from the bottom surface 132 of the base 10 and penetrate the base 10, that is, the first conductive column 24 and the second conductive column 25 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com