Method for vertical grounding down leading on inner side of composite material tower and tower

A technology of composite materials and grounding down conductors, which is applied in the configuration of grounding wires, towers, building types, etc., can solve problems such as lightning protection that have not been considered, and achieve the effect of enhancing the insulation strength against lightning impact, simple structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

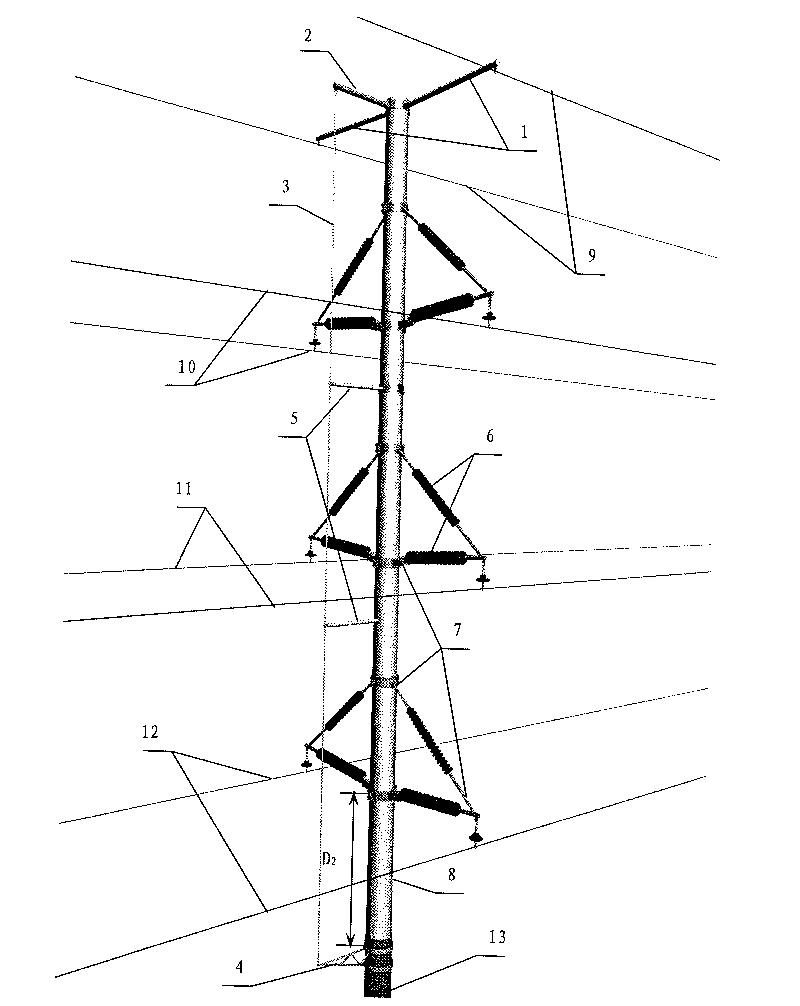

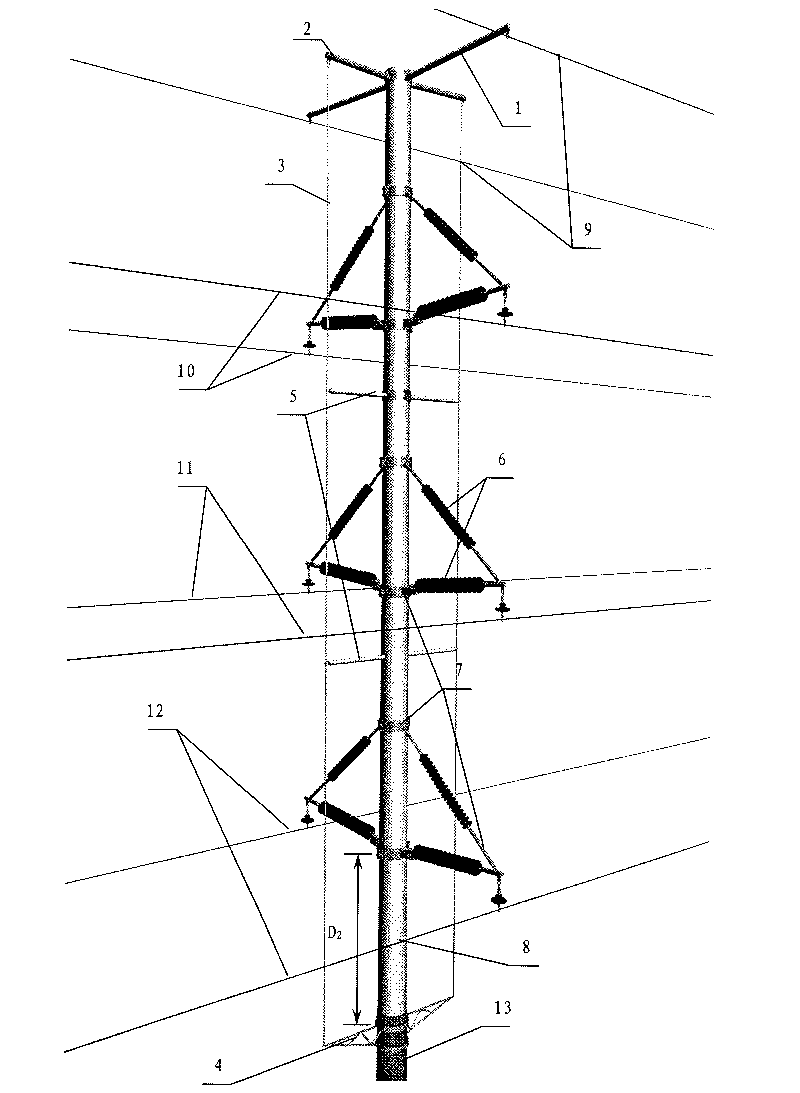

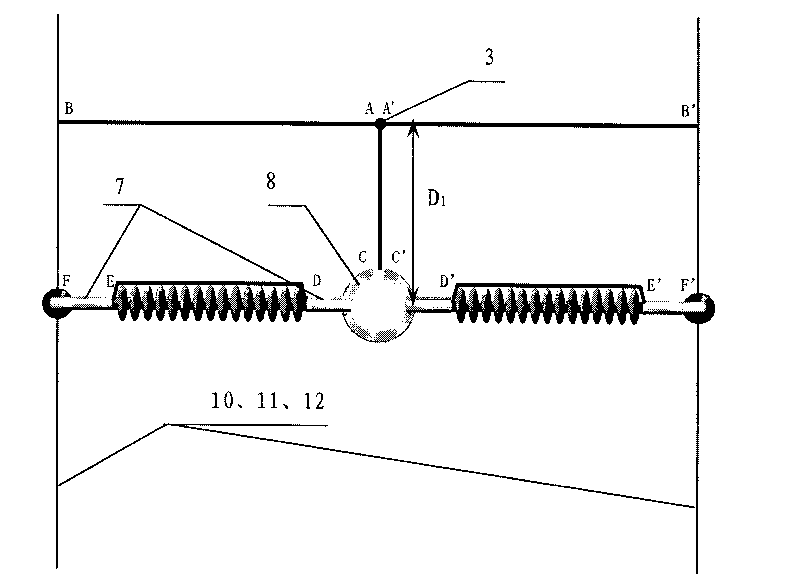

[0026] figure 1 Middle mark description: 1-ground wire cross arm, 2-ground down conductor metal cross arm, 3-ground down conductor, 4-ground down conductor metal cross arm, 5-support insulating rod, 6-composite insulator , 7-horizontal arm fittings, 8-the tower body part of the tower head, 9-ground wire, 10-upper phase wire, 11-middle phase wire, 12-lower phase wire, 13-the lower part of the tower body.

[0027] The ground wire cross arm 1 in the present invention is made of metal material, and a certain length D is drawn from the center of the ground wire cross arm 1. 1 The metal cross-arm 2 on the grounding down-conductor along the wire direction, the end of the metal cross-arm 2 on the grounding down-conducting line vertically leads down the grounding down-conductor 3, and the grounding down-conductor 3 must be below the lower phase conductor 12 distance D 2 The metal cross arm 4 is connected to the tower through another grounding down conductor. Adding the metal cross a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com