Self-cleaning device of air-conditioning filter net

A filter and self-cleaning technology, which is applied in the direction of filter separation, filter regeneration, chemical/physical/physicochemical processes of energy application, etc., can solve problems such as poor ventilation, complicated piping lines, and cannot be cleaned, etc., to achieve Simple and reliable effect of motion structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

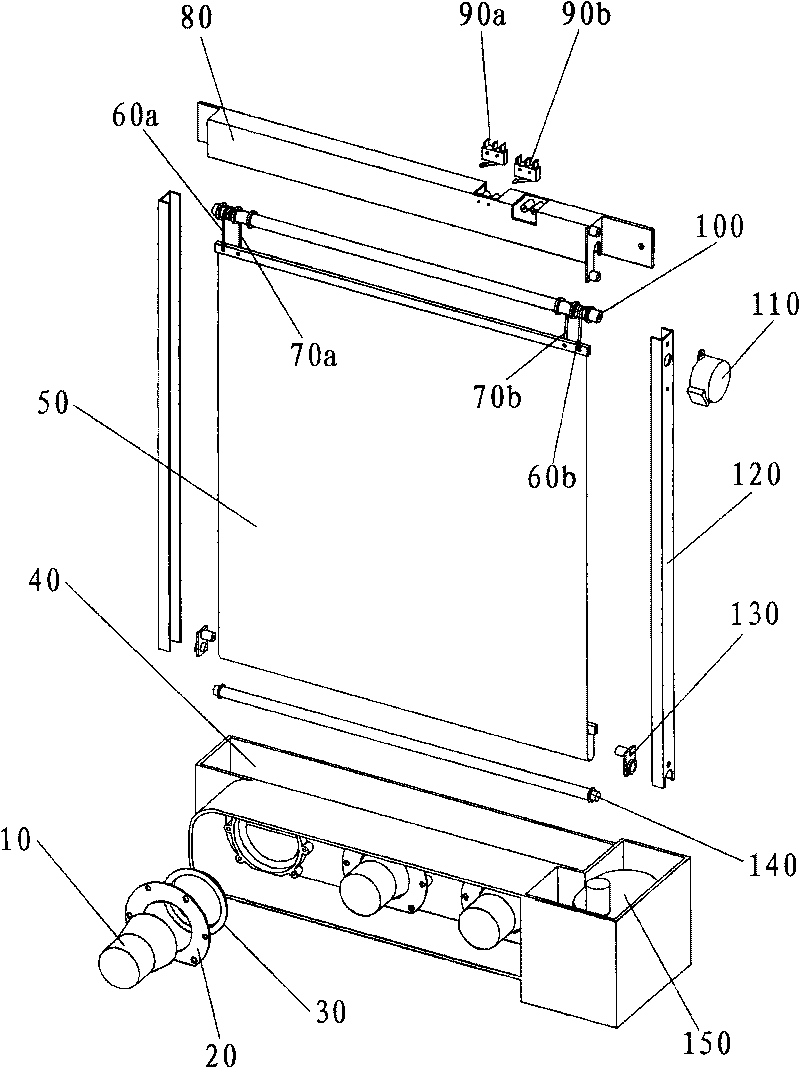

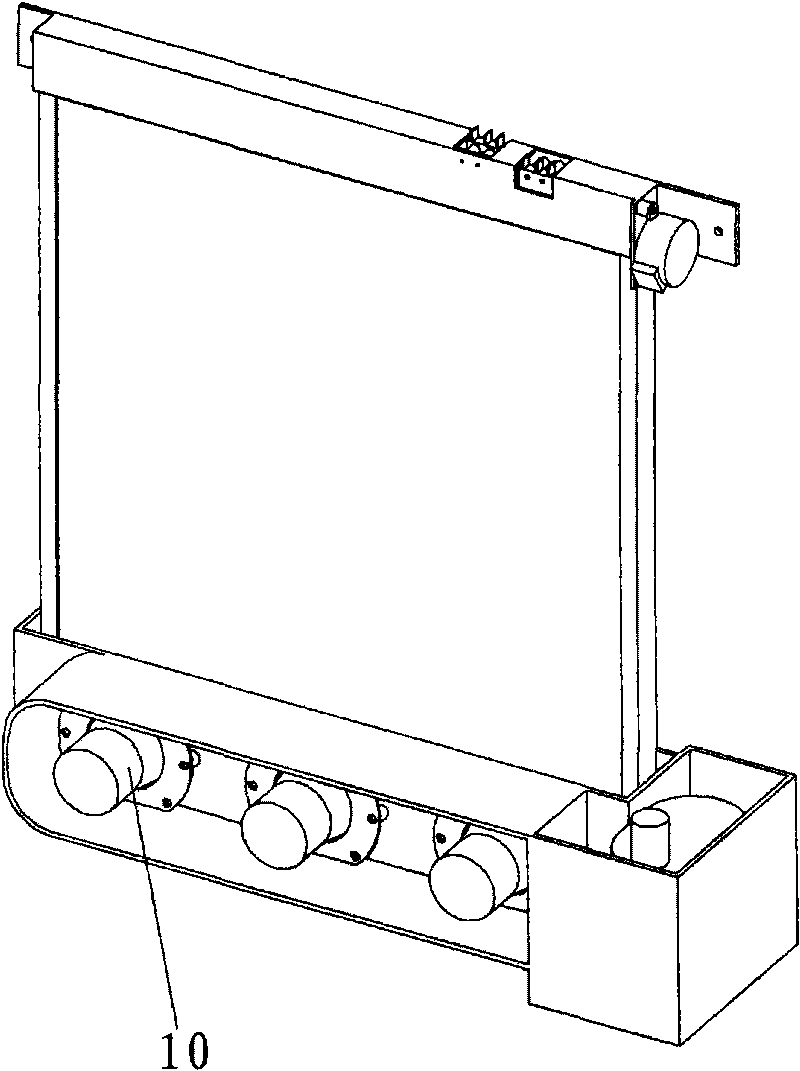

[0017] Such as figure 1 As shown, the air conditioner filter screen self-cleaning device of the present invention is installed inside the casing of the air conditioner indoor unit, and is located in front of the air conditioner suction system. refer to figure 2 The self-cleaning device for the air conditioner filter includes an ultrasonic vibrator assembly, a cleaning tank 40, a filter assembly, soft ropes 60a, 60b, 70a, 70b, an upper cover 80, travel switches 90a, 90b, an upper roller 100, a drive motor 110, The chute 120, the lower roller 140 and the water pump 150. Wherein, the ultrasonic vibrator assembly includes an ultrasonic vibrator 10 , a vibrator cover 20 and a vibrating cap 30 ; the filter screen assembly includes a soft filter screen 50 and upper and lower filter screen clamps 50 a and 50 b.

[0018] Also refer to Figure 3 to Figure 5 , the cleaning tank 40 is located at the bottom of the self-cleaning device for the air conditioner filter screen. In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com