Adjustable rotary electrical-discharge machining frock clamp

A tooling, electrical discharge machining technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve problems affecting machining accuracy, axial error, machine tool machining error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

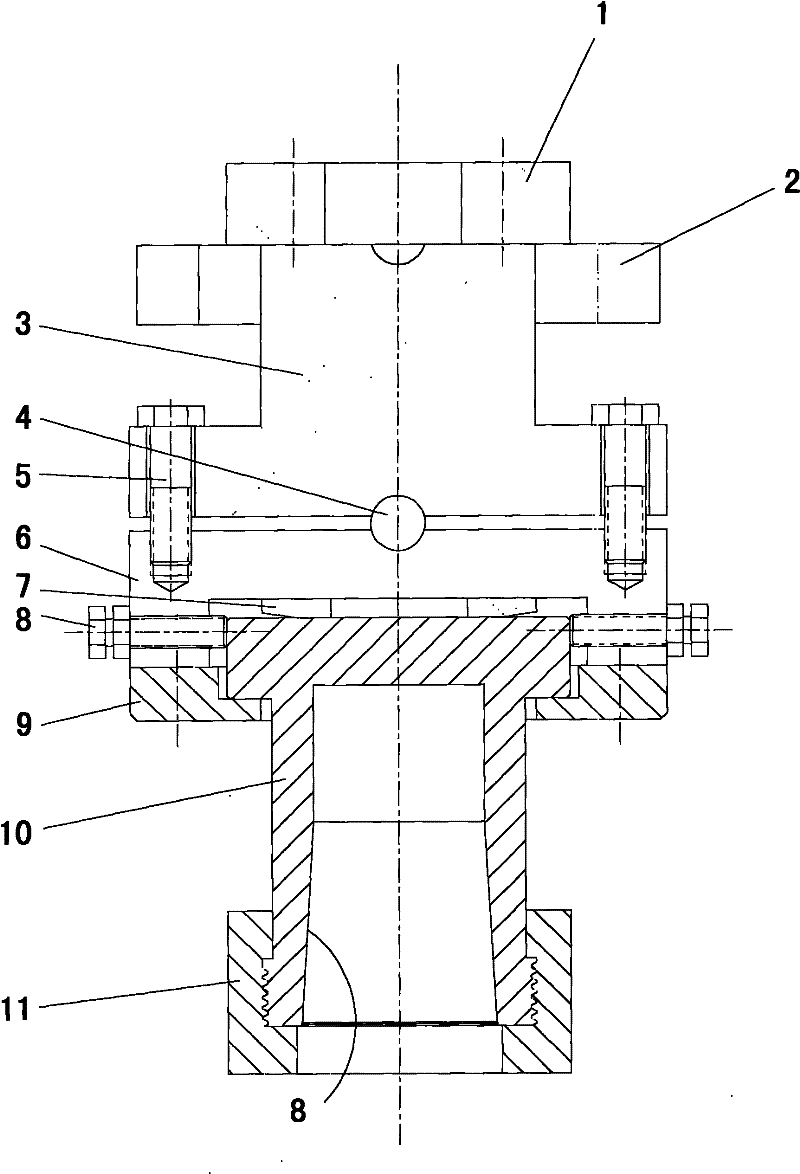

[0008] like figure 1 As shown: 3 is the upper connecting body, 6 is the lower connecting body, a relative pit is processed at the center between the upper connecting body 3 and the lower connecting body 6, and a steel ball 4 is clamped in the opposite pit, and the upper connecting body At least three (four in this embodiment) adjusting bolts 5 are evenly distributed around the connecting body 3 and the lower connecting body 6 .

[0009] There is a boss on the outside of the upper end of the electrode mounting sleeve 10 and is clamped on the inside of the lower connecting body 6. The position is limited by the gland 9, and the gland 9 and the lower connecting body 6 are fixedly connected by bolts. Around the sides of the lower connecting body 6 are provided with adjusting top wires 8 against the electrode mounting sleeve 10 , there are four adjusting top wires 8 and they are evenly distributed on the side of the lower connecting body 6 . The lower end of the electrode mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com