A method for directly preparing high-temperature superconducting flat calcined target blanks by isostatic pressing

A high-temperature superconducting and isostatic pressing technology, used in manufacturing tools, ceramic molding machines, etc., can solve the problems of difficulty in stable control of yield and quality, restricting the engineering preparation of superconducting targets, and high cost, and achieves less processing. , The effect of improving quality and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

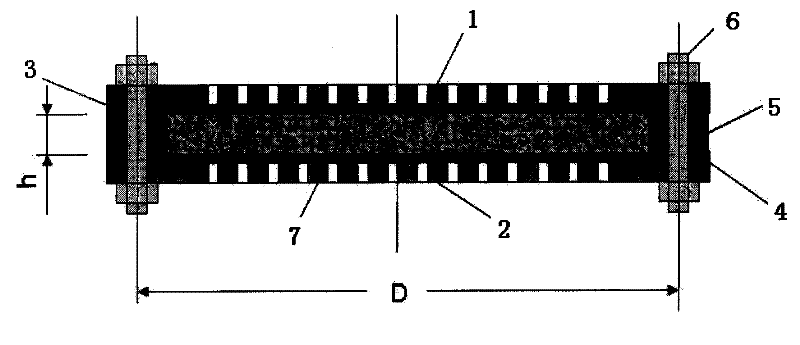

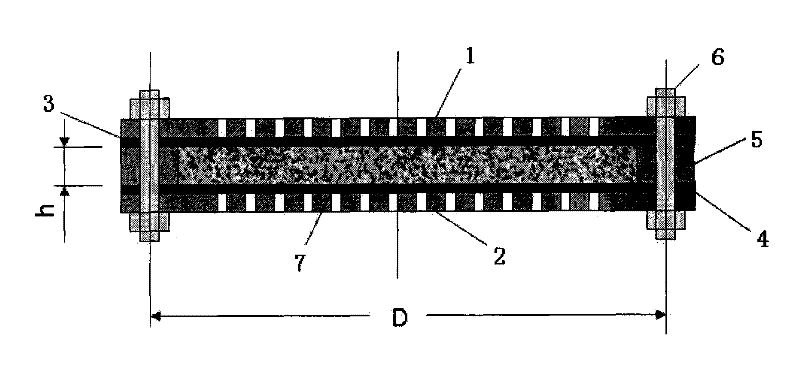

[0027] Below in conjunction with accompanying drawing, a kind of implementation mode of invention mold is described in detail:

[0028] Such as figure 1 As shown, the mold of the present invention is a simple sandwich structure. It consists of upper sieve plate 1, lower sieve plate 2, upper rubber isolation plate 3, lower rubber isolation plate 4, die ring 5 and fastening bolts 6;

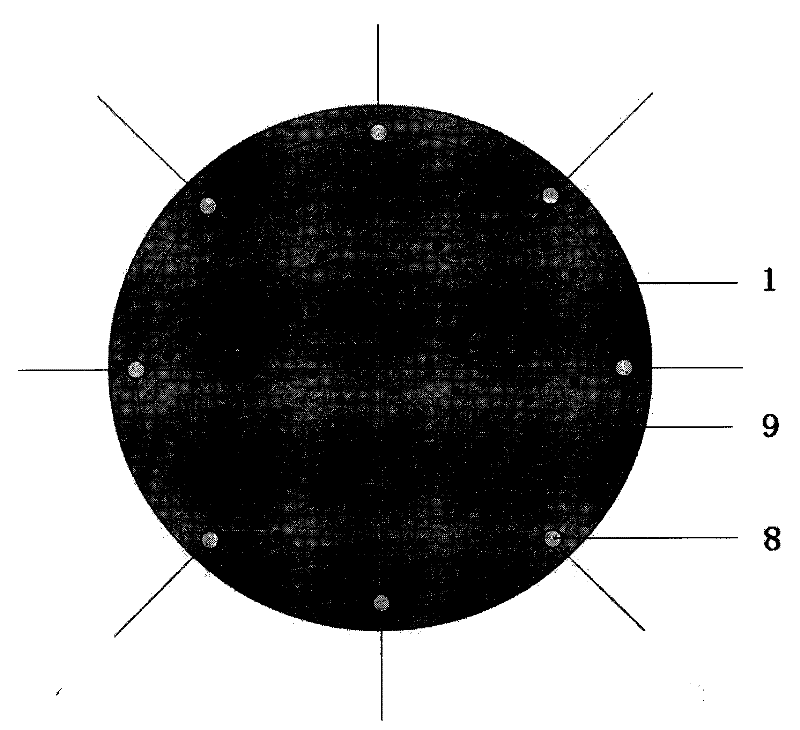

[0029] Such as figure 2 As shown, the upper sieve plate 1 and the lower sieve plate 2 are circular plates with the same shape, with sieve holes 9 evenly distributed on the surface, and eight bolt holes 8 are arranged symmetrically on the peripheral edge;

[0030] The upper rubber isolation plate 3 is placed under the upper sieve plate 1, the lower rubber isolation plate 4 is placed above the lower sieve plate 2, the mold ring 5 is cylindrical, and it is placed between the two upper and lower rubber isolation plates. 6 Fix the upper and lower sieve plates;

[0031] The pre-installed powder 7 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com