Variable flow rate intelligent sense filling valve

A filling valve and variable flow rate technology, which is applied in the field of variable flow rate intelligent induction filling valves, can solve the problems of wasting filling liquid, low production efficiency, and decreased filling accuracy, so as to improve filling speed and filling efficiency , Guarantee the effect of filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

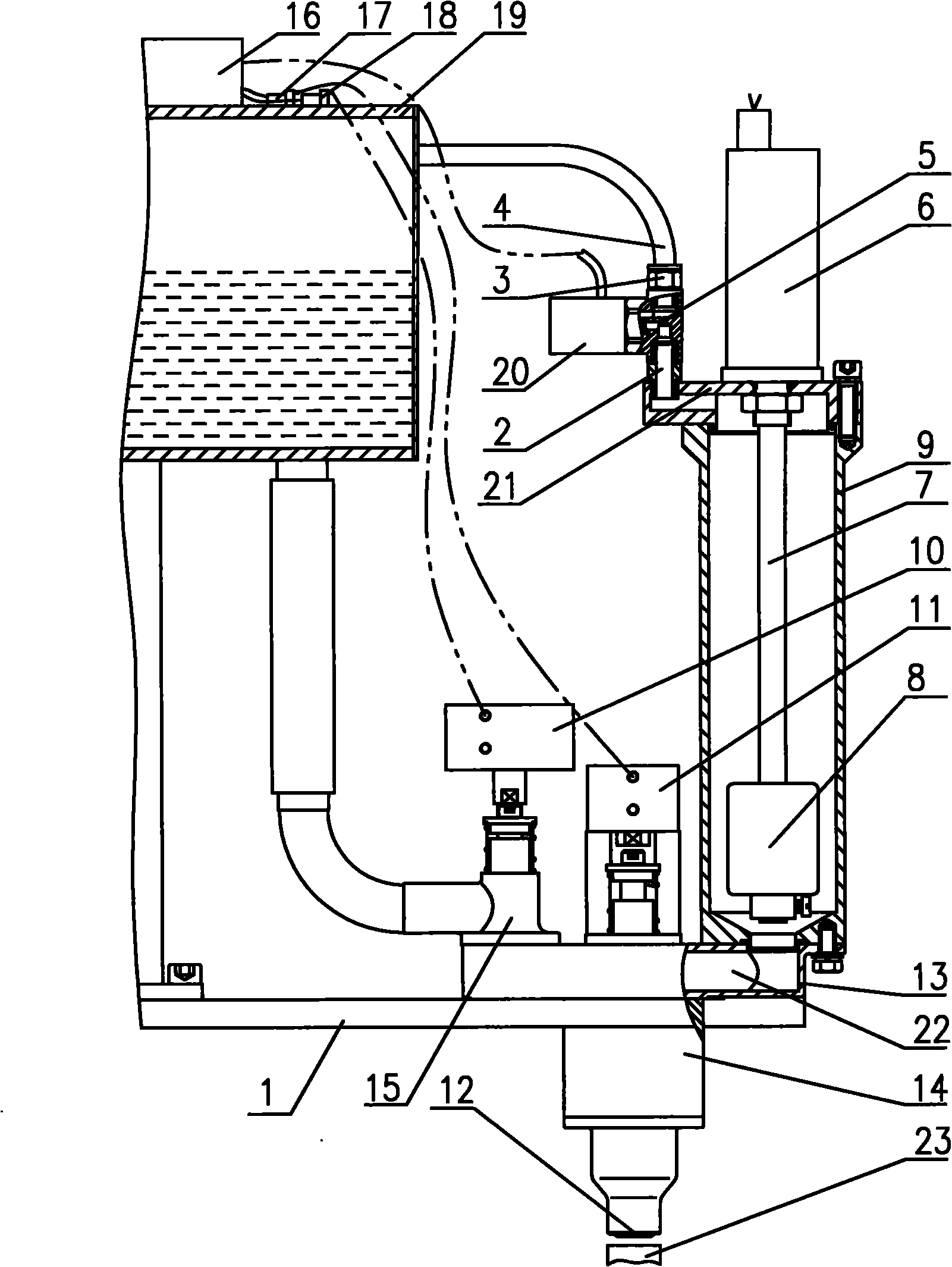

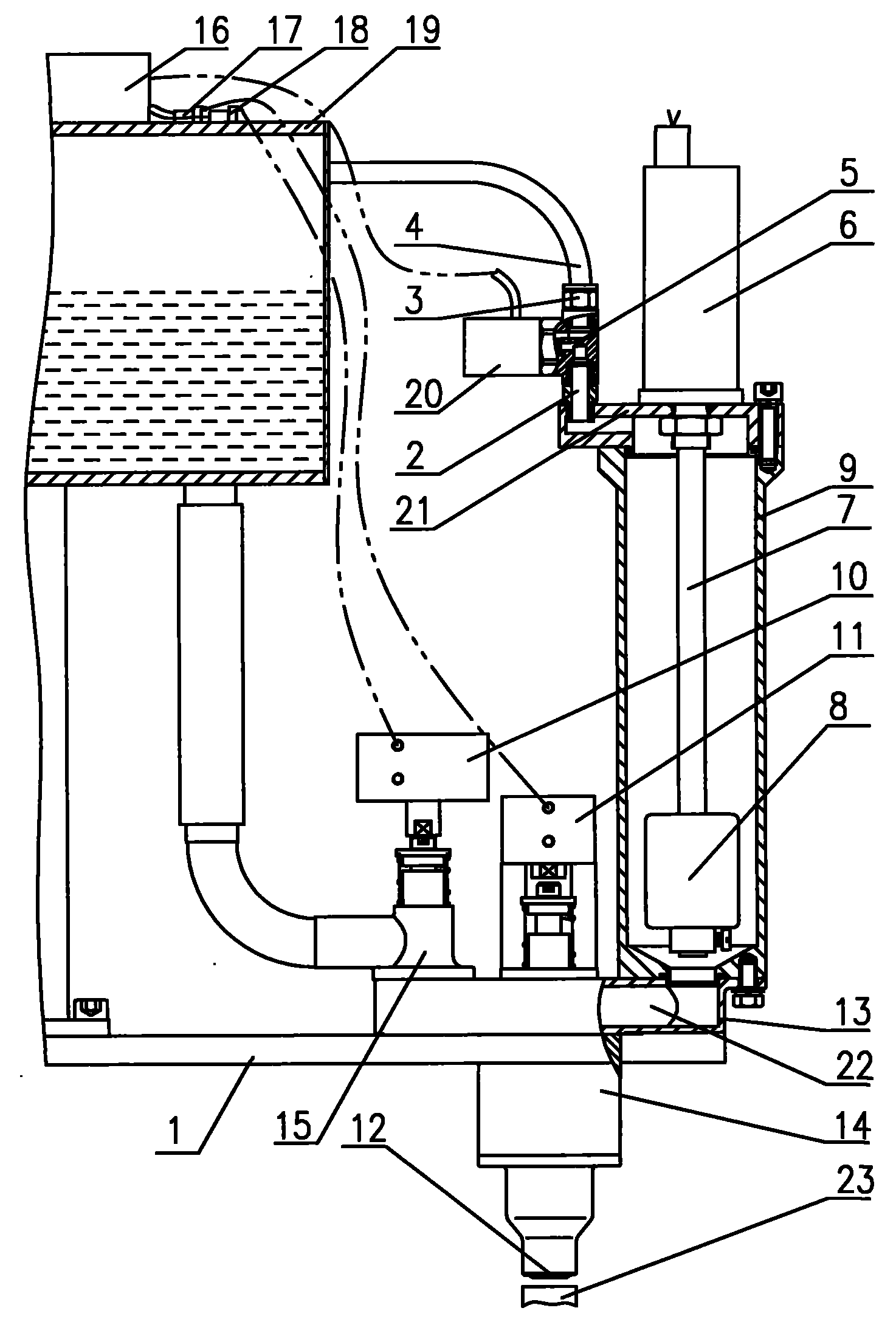

[0024] Embodiment, as shown in the figure, a variable flow rate intelligent induction filling valve includes a valve body 13, the valve body 13 is installed on a tray 1, a liquid inlet valve 15 is installed at one end of the valve body 13, and a liquid inlet valve 15 is installed at the other end. The valve cylinder 9 is equipped with a liquid outlet valve 14 in the middle, a filling nozzle 12 is installed on the liquid outlet valve 14, a liquid cylinder 19 filled with filling liquid is installed above the valve body 13, and an initial stage is arranged on the liquid cylinder 19. Filling scale and full scale, the volume of liquid contained in the liquid cylinder 19 is the same as the set volume of liquid contained in the bottle 23 when the scale is full, and the upper plane of the liquid cylinder 19 is equipped with an electric control box 16, a liquid outlet solenoid valve 17 and The liquid inlet solenoid valve 18, the liquid inlet valve 15 and the liquid outlet valve 14 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com