Method and device for endurance bending test of composite insulator

A technology of composite insulator and test method, which is applied in the field of electric power transmission component manufacturing machinery, can solve problems such as strong wind galloping of composite insulator, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with example accompanying drawing.

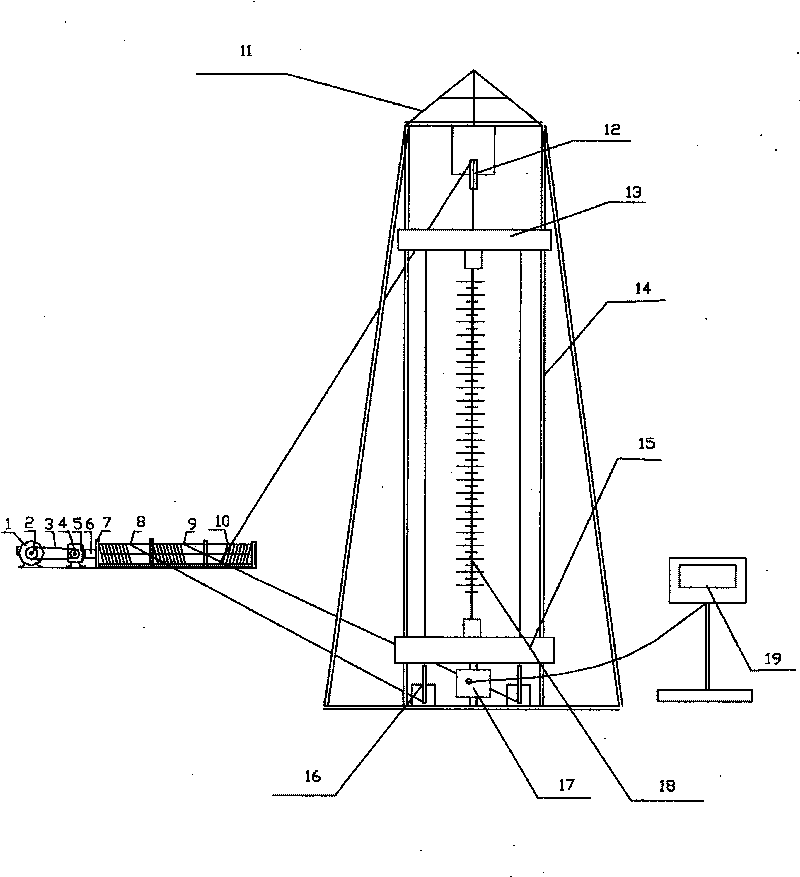

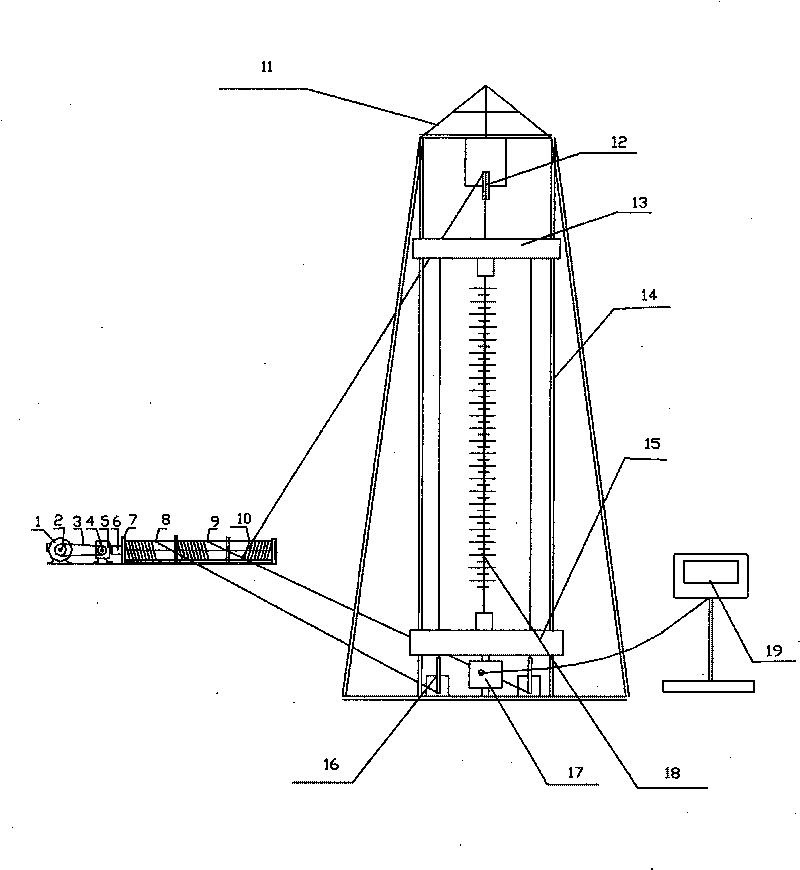

[0008] A composite insulator bending fatigue test method and device components of the present invention: 1. Motor, 2. Pulley, 3. Belt, 4. Pulley, 5. Reducer, 6. Coupling, 7. Roller, 8. Falling wire rope , 9, descending wire rope, 10, rising wire rope, 11, iron tower, 12, upper fixed pulley, 13, upper block, 14, slide rail, 15, lower block, 16, lower fixed pulley, 17, pressure sensor, 18, composite Insulator, 19, digital display meter.

[0009] The realization process of the present invention: start the motor 1 to rotate forward, drive the reducer 5 to rotate through the pulley 2, the belt 3, and the pulley 4, drive the roller 7 to rotate through the coupling 6, and drive the descending wire ropes 8 and 9 to pull the upper block 13 through the lower pulley 16 Moving downwards, a compressive load is applied to the composite insulator 18, causing the composite insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com