Cable stripping machine

A stripper and cable technology, which is applied in the direction of circuits, circuit/collector components, equipment for dismantling/armoring cables, etc., can solve the problems of increasing the safety of manual operations, inconvenient artificial intelligence operations, etc., and achieve the convenience of intelligent Operation, reduce labor intensity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

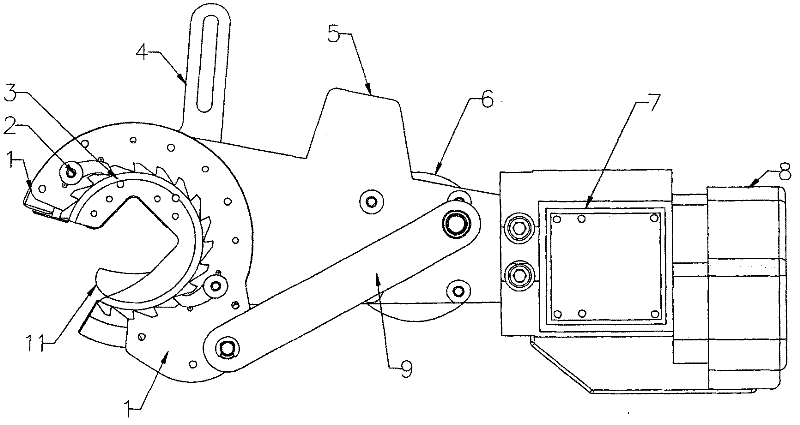

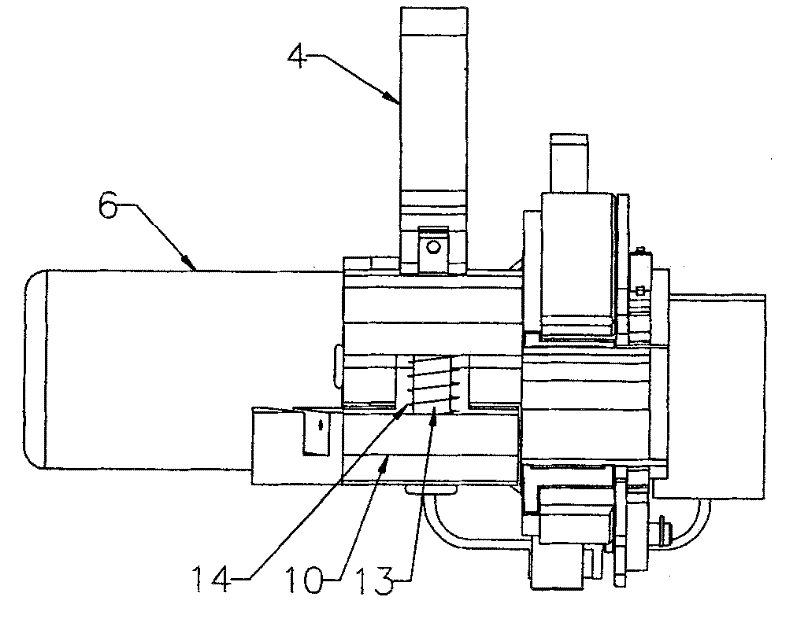

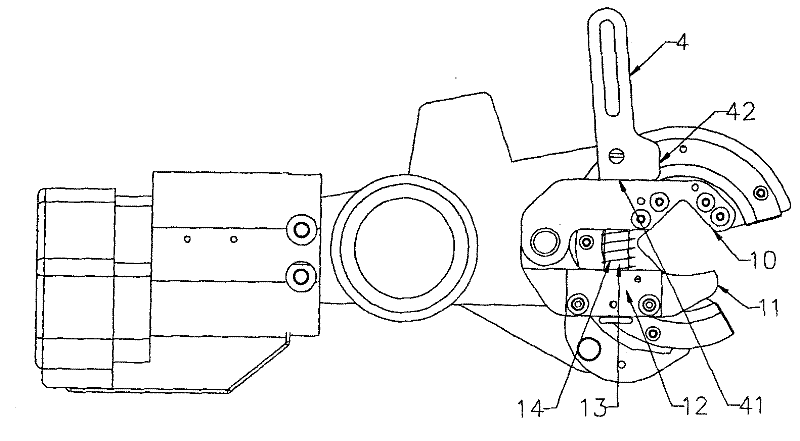

[0028] like figure 1 As shown, the cable stripper includes a blade, and also includes a fixed bracket 5, a geared motor 6, a crank linkage mechanism, a ratchet pawl mechanism, a cable clamping device, a tool mounting frame 12, an electronic control device 7 and a battery 8.

[0029] The reduction motor 6 is fixedly installed in the middle part of the fixed bracket 5, and the output end of the reduction motor 6 is connected with the crank in the crank linkage mechanism.

[0030] The ratchet and pawl mechanism is arranged at the front end of the fixed bracket 5 and includes a ratchet 3 , a ratchet 2 and a swing plate 1 . Wherein, two pawls 2 are provided to ensure its working reliability. The two pawls 2 are arranged on the oscillating plate 1, and the oscillating plate 1 and the ratchet 3 are arranged coaxially and can rotate around the axis. The swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com