Process for manufacturing high-strength hot-rolled steel sheet

A technology of hot-rolled steel sheet and manufacturing method, which is applied in the field of manufacturing high-strength hot-rolled steel sheet, can solve problems such as difficulty in applying the coiling process, achieve excellent stretch flangeability, and suppress the generation of local low-temperature parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

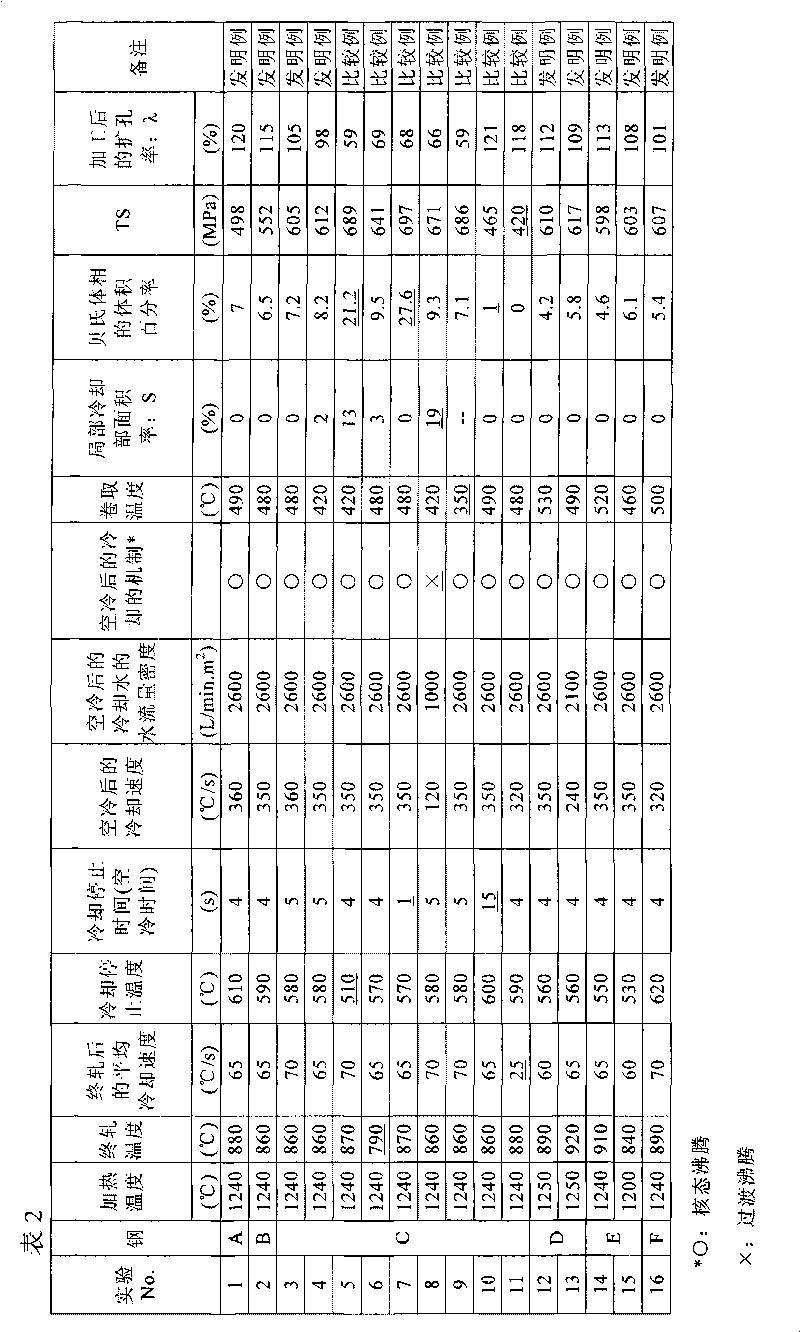

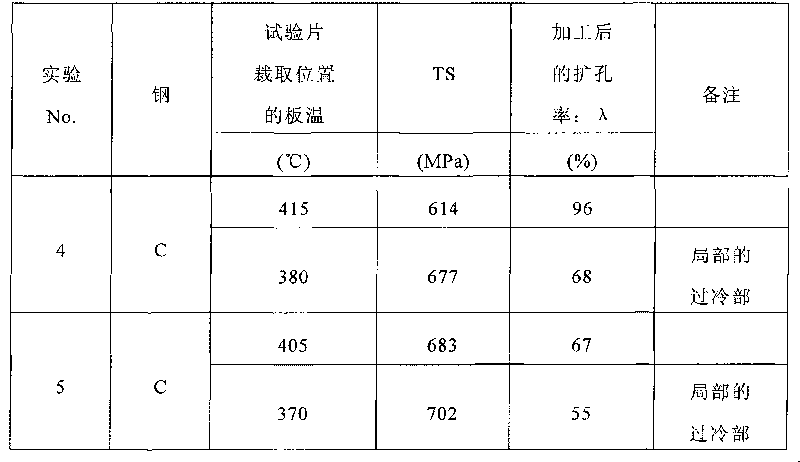

[0062] The steel slabs with the chemical compositions shown in Table 1 were hot-rolled under the hot rolling and cooling conditions shown in Table 2 to produce hot-rolled sheets with a thickness of 3.2 mm. Here, air cooling is performed during the cooling stop period after the cooling after finish rolling. Then, the above-mentioned hot-rolled sheet is subjected to a usual pickling treatment. In addition, a radiation thermometer (manufactured by NEC Sanei Co., Ltd., model: TH7800) capable of two-dimensionally measuring the surface temperature of the steel plate was installed in front of the coiling device to measure the presence or absence of local temperature deviation of the steel plate. A usual pickling treatment is performed on the above-mentioned hot-rolled sheet.

[0063] In addition, regarding the cooling after air cooling shown in Table 1, an experiment was conducted separately, and it was confirmed that it passed 2000 L / min·m 2 Above the water flux density nucleate b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com