Cane harvester

A harvester and sugarcane technology, applied in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of U-turn restriction, increase the length of the sugarcane harvester, and easily block the sugarcane outlet, and reduce intermediate links, Improve the efficiency of mechanized harvesting, easy to turn around and walk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

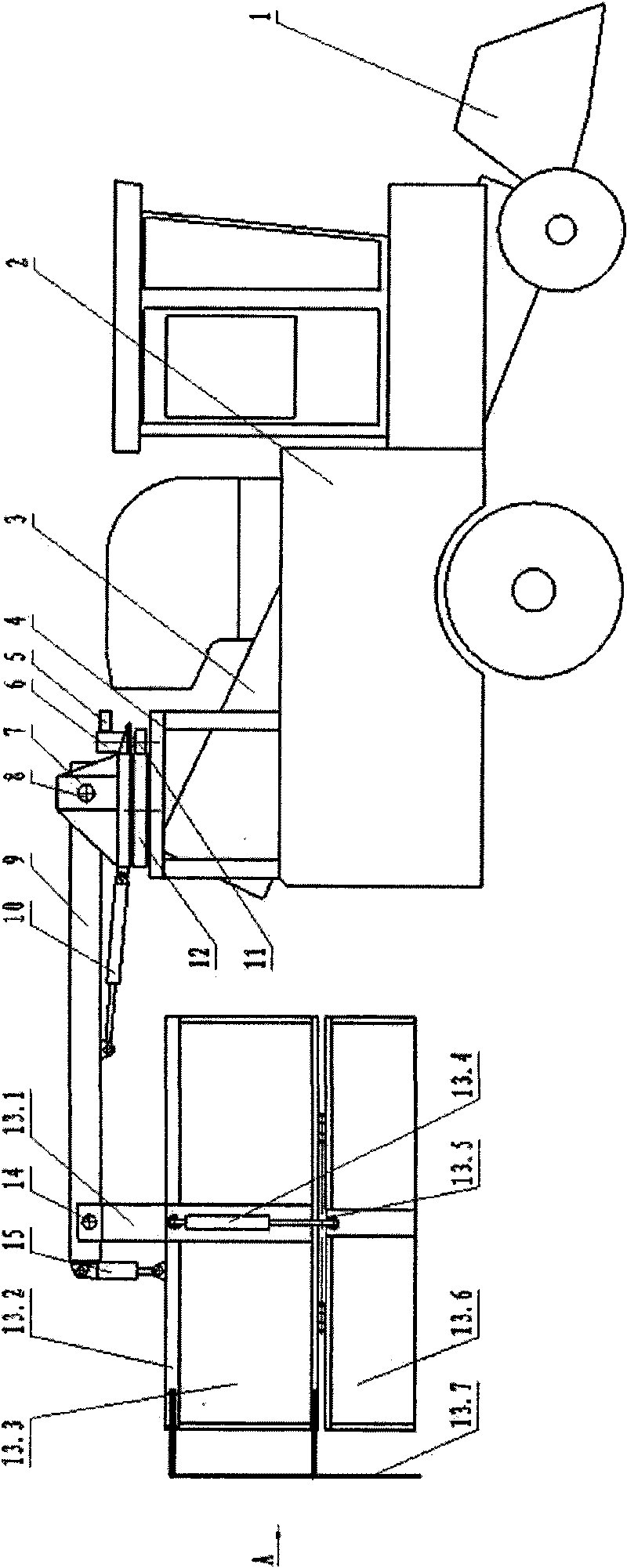

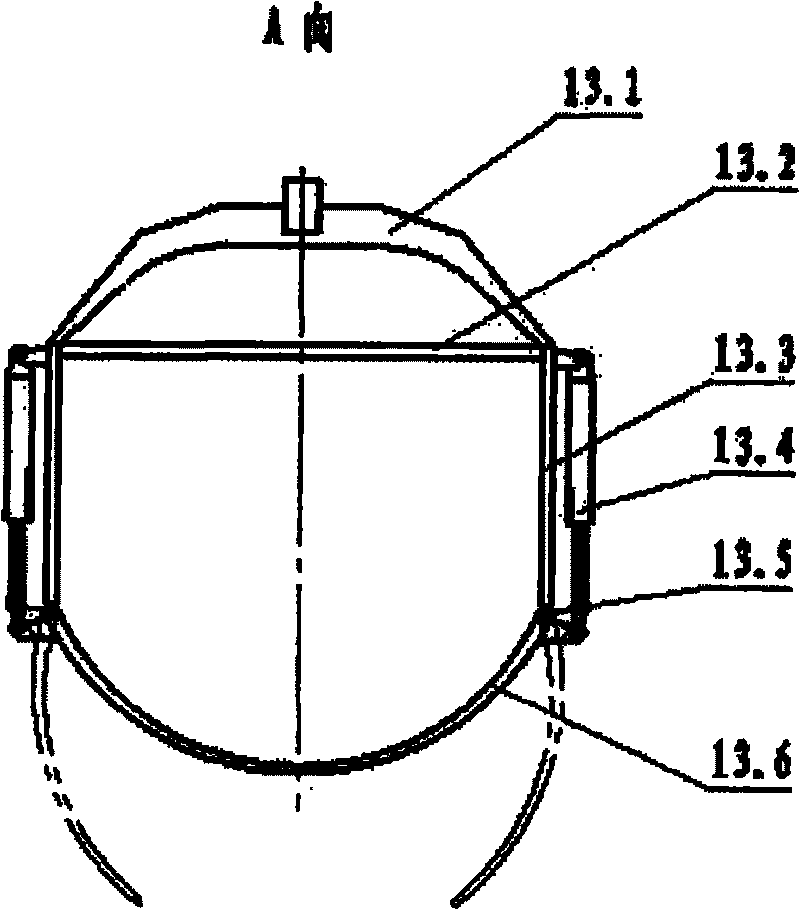

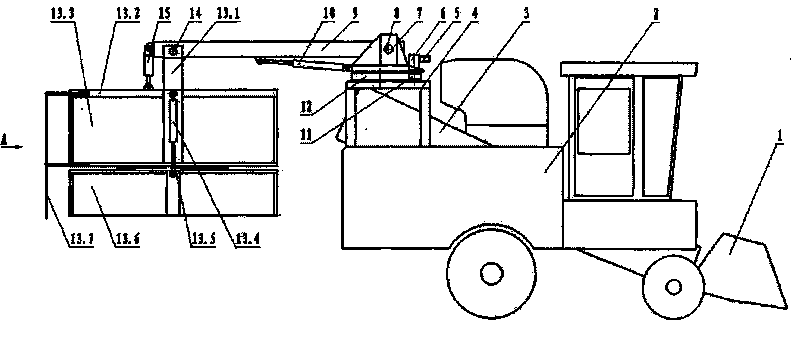

[0015] Below in conjunction with accompanying drawing example, structure of the present invention is described in further detail:

[0016] figure 1 , figure 2 The shown sugarcane harvester has a trolley 2, and a header 1 that is used to lift up and cut off the root of the sugarcane is installed on the front end of the trolley 2, and a device for stripping and transporting the cut sugarcane is housed in the trolley 2. Sugarcane delivery channel 3, these parts all are existing parts on the existing sugarcane harvester. In addition, there is a support 4 installed on the trolley 2 above the sugarcane delivery channel 3, the support 4 is equipped with the same movable base 7 as the current rotary crane, and the movable base 7 is equipped with a motor driven by a hydraulic motor 5 through a reduction box 6. Drive gear 11, drive gear 11 meshes with ring gear 12 fixedly mounted on the bracket 4, forward rotation or reverse rotation of hydraulic motor 5 can correspondingly drive mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com