Composite material sheet cutting machine

A composite material and cutting machine technology, applied in the field of mechanical processing, can solve problems such as surface stress and corner burrs, and achieve the effects of low cost, improved processing accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

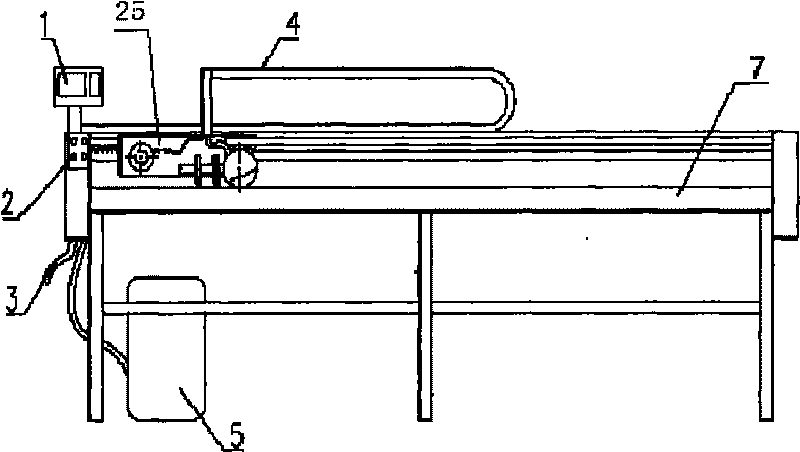

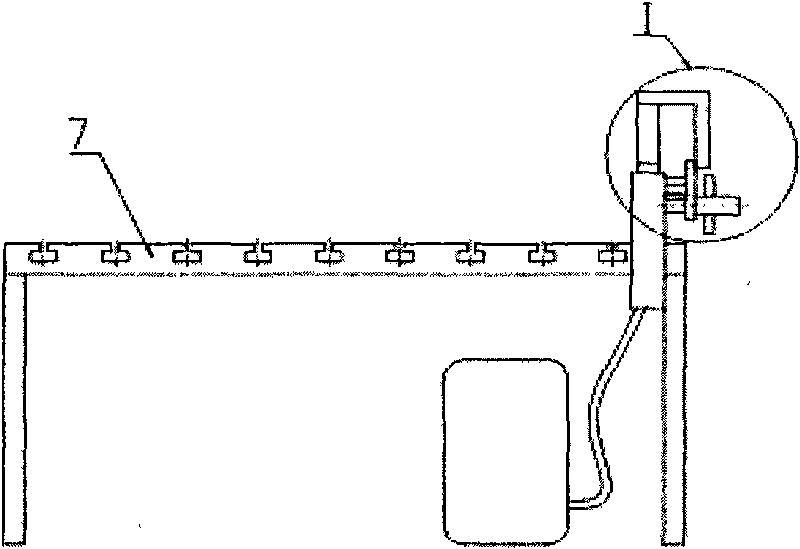

[0021] This embodiment is a composite material plate cutting machine with a processable thickness of 20mm, including a digital display 1, a pneumatic control unit 2, a workbench 7, a vacuum cleaner 5, a scale 8, a moving bracket 10, a cutting saw 12 and a pneumatic motor 13.

[0022] The cutting saw adopts imported pneumatic high-speed cutting tools and adopts pneumatic control. The moving working stroke of the cutting saw is 4.5m; the feed speed is 0.5-5m / min and adjustable, and the straightness is ≤0.30 / full length; the rotating speed of the cutting saw is 15000rpm; the size of the disc cutter is d=100mm, and the linear speed is 78.5 m / s, cutting depth 26mm. The linear feed of the cutting saw along the length of the table is realized by the transmission system.

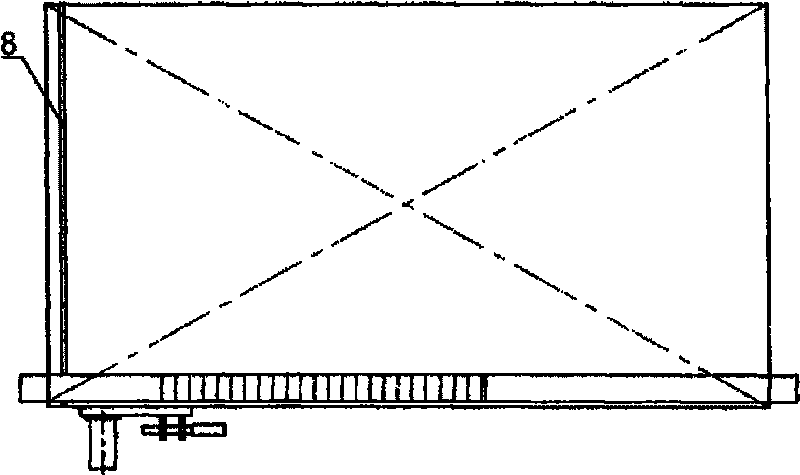

[0023] figure 1 As shown, the upper surface of the workbench 7 is processed with several T-shaped grooves for fixing the plates; the beam 9 is fixed above the side edge of the workbench 7 through a column; the di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap