Method and device for producing a printed product with a double-sided cover

A printed matter, double-sided technology, applied in the field of printed matter equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

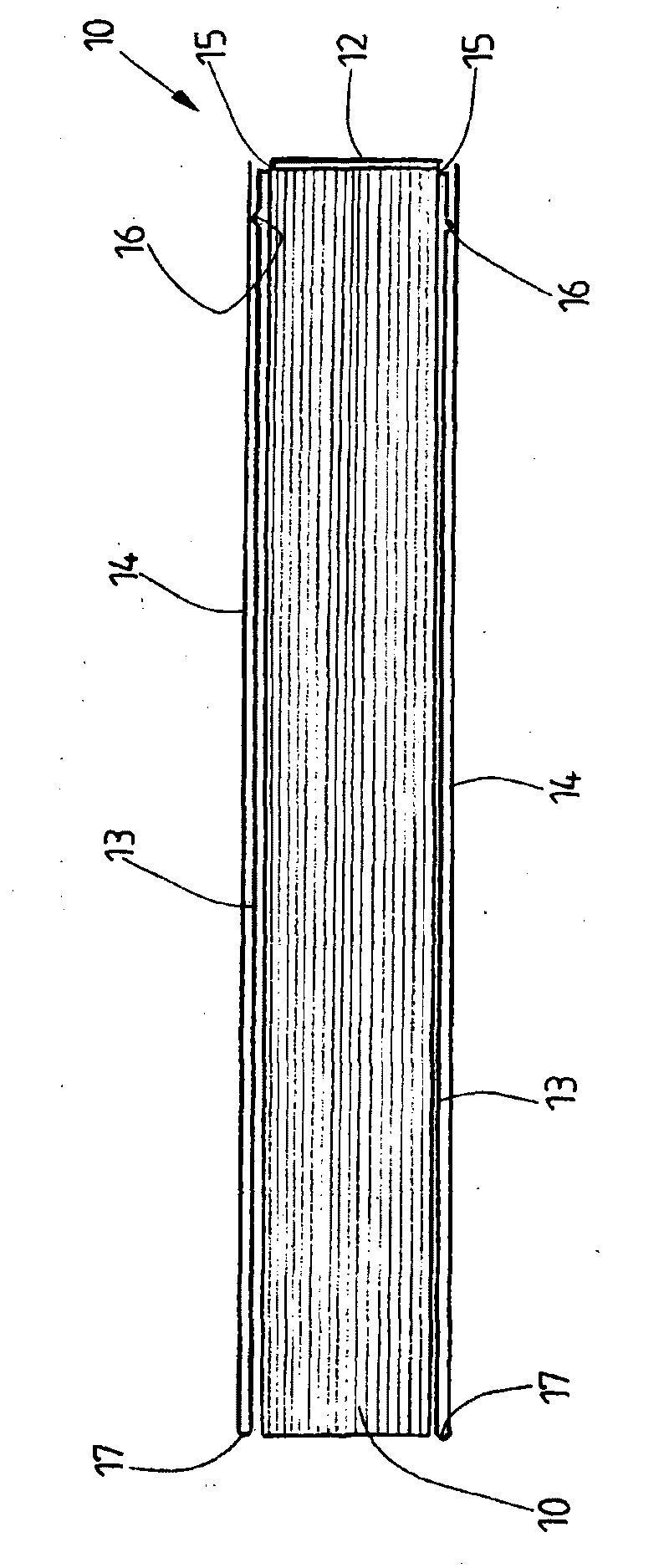

[0023] The invention relates to the production of a special printed matter. this is in figure 1 The printed matter shown in has a book block 10 and a double-sided cover 11. The cover 11 has a central spine 12 which is connected to the spine of the book block 10, preferably glued together. Both longitudinal sides of the spine 12 are each connected to a cover leaf 13 of the same size in the illustrated exemplary embodiment. A flap 14 adjoins the outside of each longitudinal edge of the cover leaf 13 . In the exemplary embodiment shown, the flaps 14 are of the same size and completely cover the respective cover leaf 13 . It is also conceivable that the flap leaf 14 is slightly shorter or longer than the cover leaf 13 . The flip page 14 is turned over from the outside relative to the cover page 13 . Thus, the individual cover pages 13 are directly attached to a flat side of the book block 10, while the corresponding flap 14 is folded relative to the respective cover page 13 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com