Preparation method of low-carbon alkane dehydrogenation catalyst

A technology for dehydrogenation catalysts and low-carbon alkanes, which is applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve problems such as interactions and positions that have not been clarified, so as to prolong the single-pass operation cycle and reduce operating costs , highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

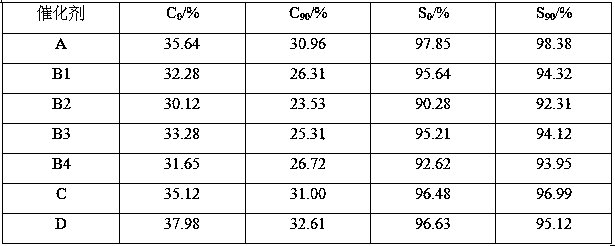

Examples

Embodiment 1

[0020] Preparation of Pt-Sn impregnation solution: Dissolve 0.68g of chloroplatinic acid in 100ml of deionized water, then add 0.74g of crystalline tin tetrachloride to the solution, and stir to dissolve it. Add 3g of EDTA to the solution and stir thoroughly to obtain a Pt-Sn impregnation solution.

[0021] Weigh 50g spherical γ-Al 2 o 3 The carrier was placed in a rotary evaporator and vacuumed for 60 min. The impregnating solution was sucked into the rotary evaporator, the vacuum pump was turned off, and the impregnation was carried out at room temperature and pressure for 6 hours.

[0022] Then, the temperature of the water bath was raised to 80° C., the catalyst was vacuum-dried, then transferred into a beaker, and dried in an oven at 110° C. for 15 hours. The catalyst was then transferred to a muffle furnace and calcined at 500°C for 5 hours. The above catalyst is impregnated with an aqueous solution of potassium nitrate, dried and calcined to obtain the final catalys...

Embodiment 2

[0042] Preparation of Pt-Sn impregnation solution: Dissolve 0.41g of chloroplatinic acid in 100ml of deionized water, then add 1.5g of crystalline tin tetrachloride to the solution, and stir to dissolve it. Then add 4g of EDTA to the solution and stir thoroughly to obtain a Pt-Sn impregnating solution.

[0043] Weigh 50g spherical θ-Al 2 o 3 The carrier was placed in a rotary evaporator and vacuumed for 50 min. The impregnating solution was sucked into the rotary evaporator, the vacuum pump was turned off, and the impregnation was carried out at room temperature and pressure for 5 hours.

[0044] Then the temperature of the water bath was raised to 70° C., the catalyst was vacuum-dried and then transferred into a beaker, and dried in an oven at 120° C. for 11 hours. The catalyst was then transferred to a muffle furnace and calcined at 510°C for 4 hours. The above catalyst is impregnated with an aqueous solution of zinc nitrate, dried and calcined to obtain the final cataly...

Embodiment 3

[0047] Preparation of Pt-Sn impregnation solution: Dissolve 0.82g of chloroplatinic acid in 100ml of deionized water, then add 0.44g of crystalline tin tetrachloride to the solution, and stir to dissolve it. Add 3g of EDTA to the solution and stir thoroughly to obtain a Pt-Sn impregnation solution.

[0048] Weigh 50g spherical γ-Al 2 o 3 The carrier was placed in a rotary evaporator and vacuumed for 60 min. The impregnating solution was sucked into the rotary evaporator, the vacuum pump was turned off, and the impregnation was carried out at room temperature and pressure for 7 hours.

[0049] Then, the temperature of the water bath was raised to 85° C., the catalyst was vacuum-dried, then transferred into a beaker, and dried in an oven at 110° C. for 10 hours. Then the catalyst was moved to a muffle furnace and calcined at 520°C for 3 hours. The above-mentioned catalyst is then impregnated with an aqueous solution of gallium nitrate, dried and calcined to obtain the final ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com