Bottle opener

A corkscrew and wine bottle technology, applied in the field of corkscrews, can solve the problems of laborious, dangerous, and difficult for women to pull out cork stoppers, and achieve the advantages of simplifying the operation of inflating and removing corks, low manufacturing cost, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

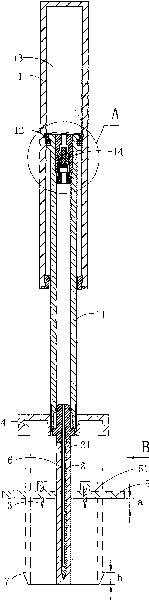

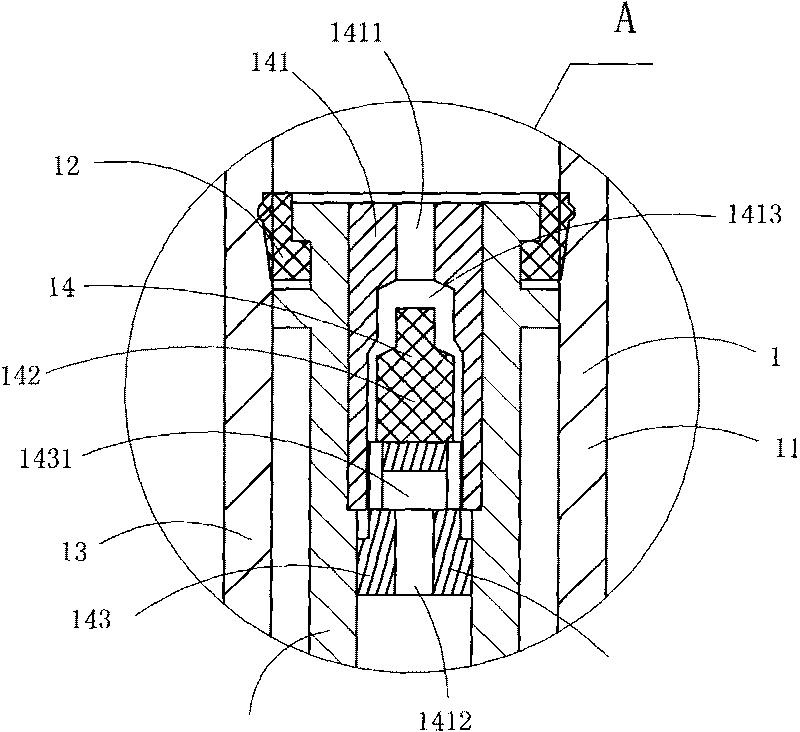

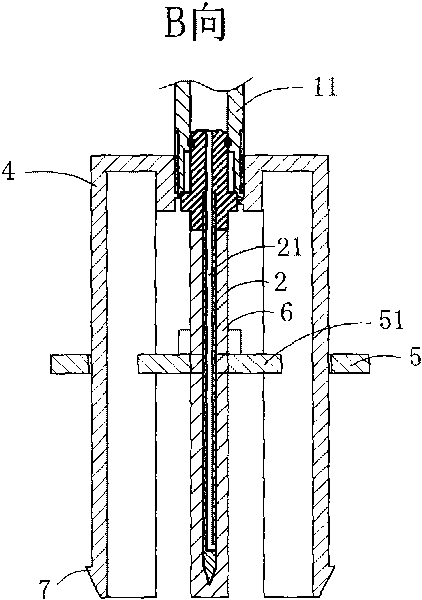

[0038] Figure 1 to Figure 8 A first embodiment of the invention is shown in which, figure 1 It is a half-sectional view of the first structure of the present invention; figure 2 for figure 1 Partial enlarged schematic diagram of A; image 3 for figure 1 A schematic diagram of a partial half-section structure of the bottle opener shown when viewed from the angle B; Figure 4 for figure 1A schematic diagram of a three-dimensional structure in which the push plate is sleeved on the bottle mask in the shown bottle opener; Figure 5 for figure 1 A schematic diagram of a three-dimensional structure of the bottle mask in the bottle opener shown; Image 6 for figure 1 A schematic diagram of a three-dimensional structure of the push plate in the bottle opener shown; Figure 7 for Image 6 The schematic diagram of the three-dimensional structure of the push plate when viewed from another angle; Figure 8 for Image 6 The push plate shown is a cross-sectional view along the...

Embodiment 2

[0055] Figure 9 It is a half-sectional view of the second structure of the present invention, showing the second specific implementation manner of the present invention.

[0056] This embodiment is a bottle opener, which is basically the same as Embodiment 1, except that the present embodiment is no longer provided with a push plate 5, and the cutting knife 3 directly protrudes from the top side wall of the bottle mouth mask 4. on the bottom wall.

[0057] When this embodiment is in use, after putting the bottle mask on the mouth of the wine bottle, press firmly, the cutter will still pierce the packaging film at the mouth of the wine bottle, go deep into the cork, and then rotate the bottle mask to drive the cutting knife. The knife rotates, so that the cutting knife cuts and opens the packaging film wrapped at the mouth of the wine bottle during the rotation.

Embodiment 3

[0059] Figure 10 It is a half-sectional view of the third structure of the present invention, showing the third specific implementation manner of the present invention.

[0060] This embodiment is a bottle opener, which is basically the same as that of Embodiment 1, except that the present embodiment does not set the bottle mask 4 and the push plate 5, and the cutter 3 is directly arranged on the top of the outer cylinder 13 in the inflator 1 , and the periphery of the cutter 3 is also provided with an annular baffle 9 for preventing the cutter 3 from being exposed.

[0061] When this embodiment is in use, first press the end with the cutter on the mouth of the wine bottle, the cutter will still pierce the packaging film at the mouth of the wine bottle, go deep into the cork, and then rotate the bottle mask to drive the cutter to rotate , so that the cutter cuts and opens the packaging film wrapped at the mouth of the wine bottle during the rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com