Anti-electrostatic crane tube telescopic oil drain device

An oil discharge device and anti-static technology, which can be used in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., and can solve problems such as economic loss and personal injury, safety hazards of crane oil discharge pipelines, and easy generation of static electricity. , to achieve significant economic and social benefits, avoid economic losses and personal injury accidents, prevent burning and explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

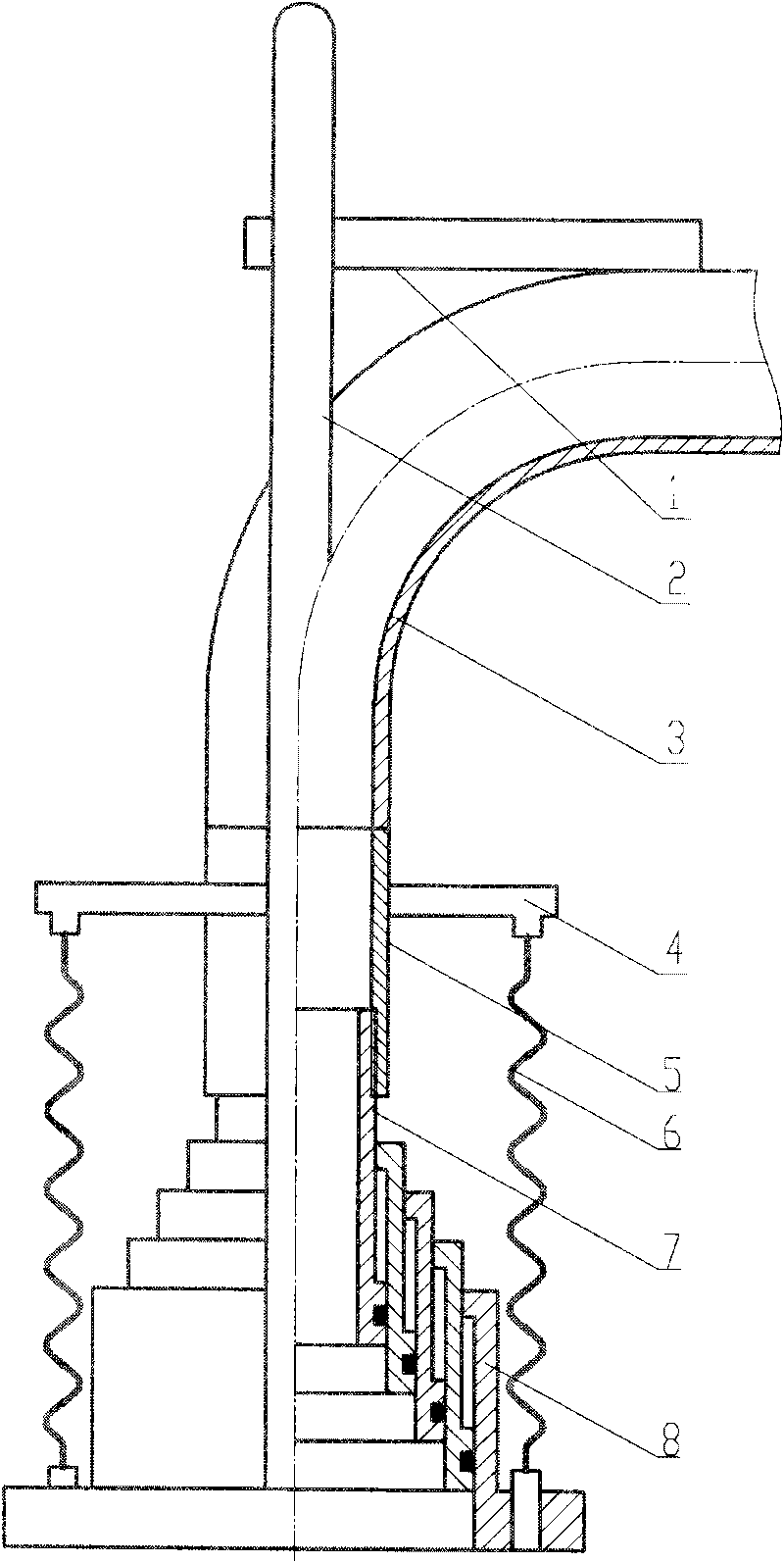

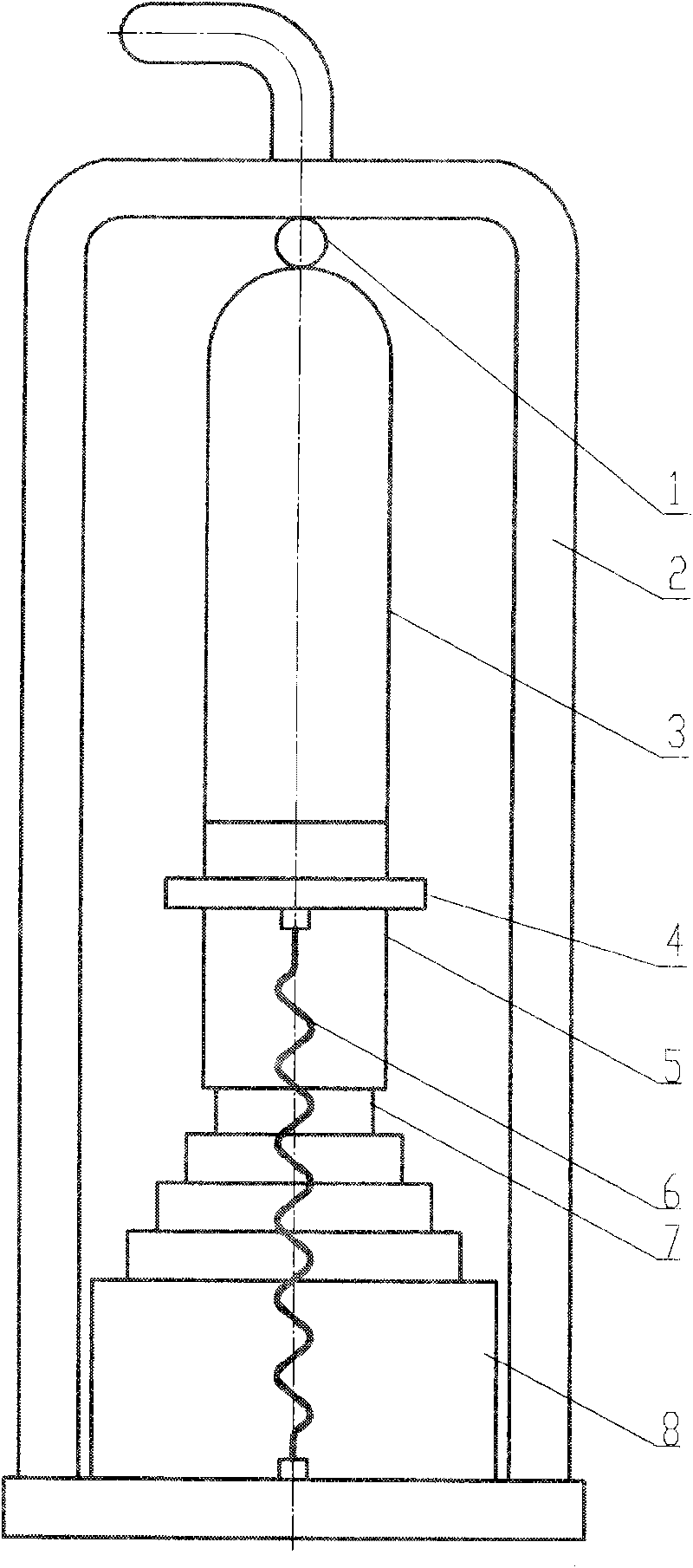

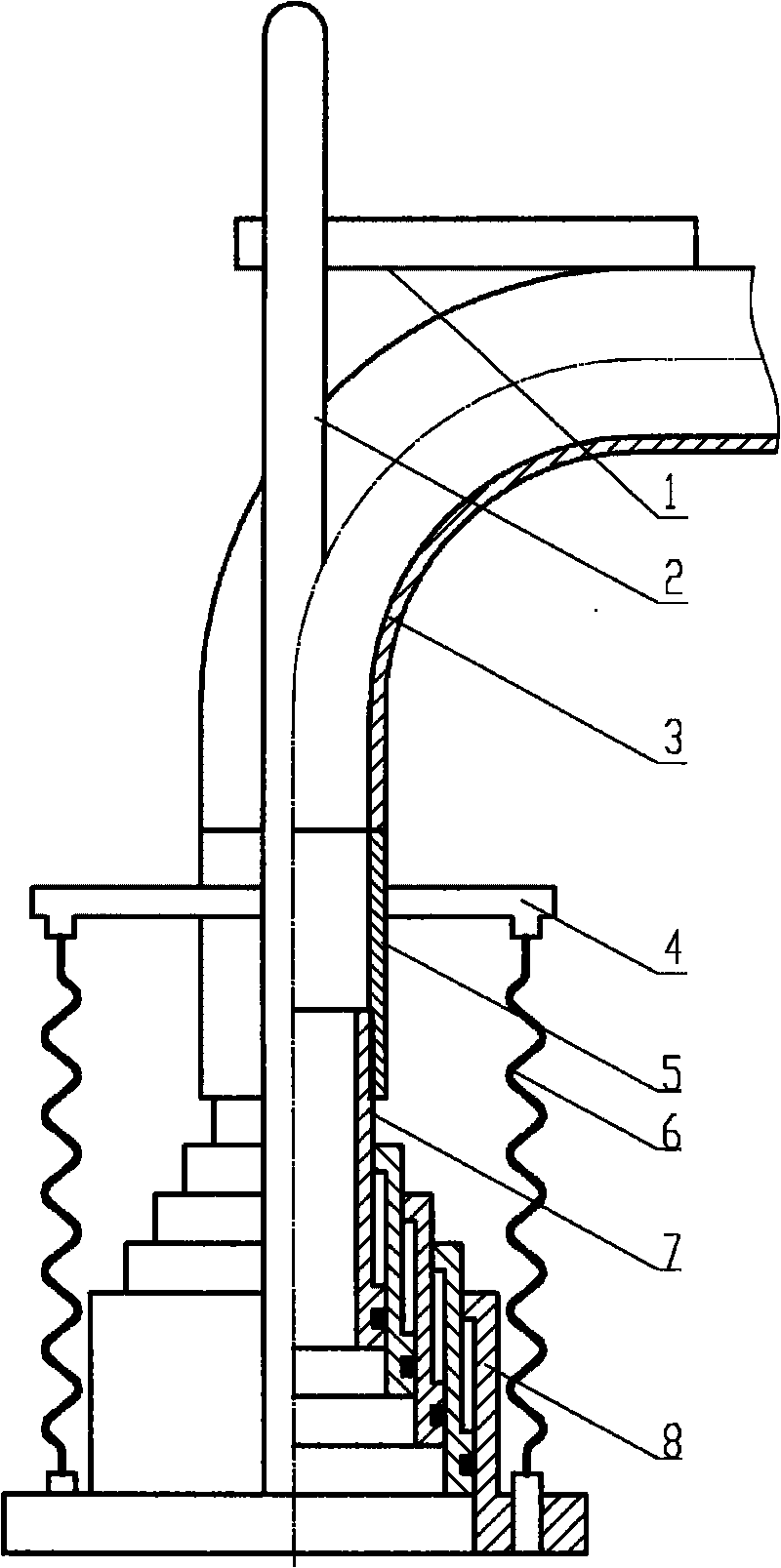

[0008] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0009] As can be seen from the figure, the embodiment of the present invention is composed of a hanging rod 1, a bracket 2, a crane tube 3, a spring frame 4, a connecting pipe 5, a spring 6, a fixed pipe 7, and a telescopic sleeve 8. The material of the telescopic sleeve 8 is nylon. The tube 5 is welded to the lower end of the crane tube 3, the fixed tube 7 is threadedly connected with the connecting tube 5, the lower end of the fixed tube 7 has a shoulder, and the telescopic sleeve 8 is composed of multi-stage mutual fittings, and the lower end of each telescopic sleeve 8 is provided with a shoulder, which is suspended from each other At the shoulder, the first-stage telescopic sleeve 8 is set outside the fixed pipe 7, and is suspended from the shoulder at the lower end of the fixed pipe 7. The lower end of the spring 6 is hung on the lower side of the lowermost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com