Knurling aluminium foil paper for cigarette, knurling device and production method thereof

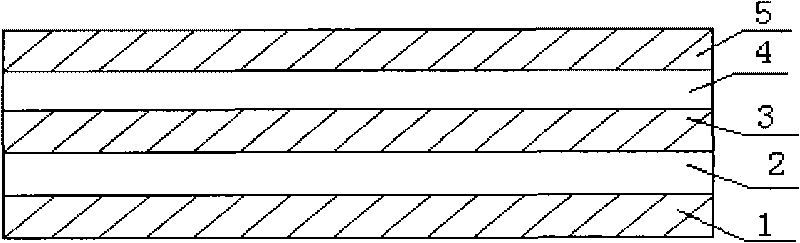

A technology of aluminum foil paper and embossing, which is applied in the direction of specific visual effect coating, machining/deformation, etc., which can solve the problems of unsightly appearance, blurred patterns of embossed aluminum foil paper, reducing the embossing effect and anti-counterfeiting effect of embossed aluminum foil paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

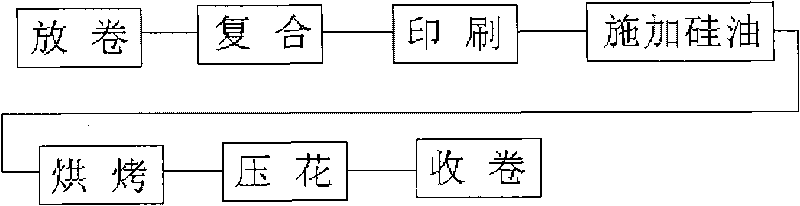

[0025] a. The backing paper and aluminum foil paper are unrolled, and the unwinding tension is controlled at 6N; the unwinding machine speed is controlled at 85m / min;

[0026] b. Sizing and compounding, the amount of sizing is 2.0g / m 2 , composite pressure 0.2MPa;

[0027] c. Printing;

[0028] d. Silicone oil is applied on the surface of aluminum foil;

[0029] e. Baking, the temperature of the upper box is controlled at 100°C, and the temperature of the lower box is controlled at 180°C;

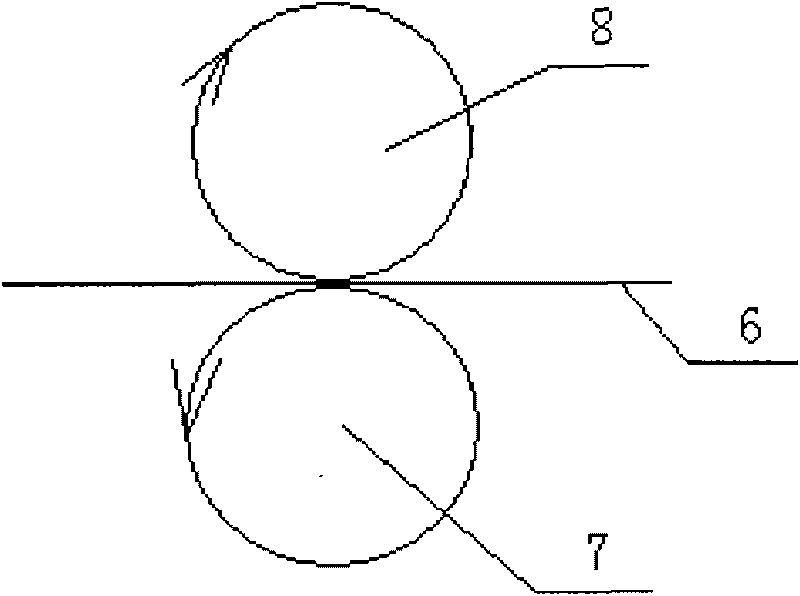

[0030] f. Embossing;

[0031] g. Rewinding, the winding tension is controlled at 5N, and the speed of the winding machine is synchronized with that of the unwinding machine.

Embodiment 2

[0033] a. The backing paper and aluminum foil paper are unrolled, and the unwinding tension is controlled at 15N; the unwinding machine speed is controlled at 90m / min;

[0034] b. Sizing and compounding, the amount of sizing is 3.0g / m 2 , composite pressure 0.4MPa;

[0035] c. Printing;

[0036] d. Silicone oil is applied on the surface of aluminum foil;

[0037] e. Baking, the temperature of the upper box is controlled at 150°C, and the temperature of the lower box is controlled at 200°C;

[0038] f. Embossing;

[0039] g. Rewinding, the winding tension is controlled at 6N, and the speed of the winding machine is synchronized with the speed of the unwinding machine.

Embodiment 3

[0041] a. The backing paper and aluminum foil paper are unrolled, and the unwinding tension is controlled at 10N; the unwinding machine speed is controlled at 88m / min;

[0042] b. Sizing and compounding, the amount of sizing is 2.5g / m 2 , composite pressure 0.3MPa;

[0043] c. Printing;

[0044] d. Silicone oil is applied on the surface of aluminum foil;

[0045] e. Baking, the temperature of the upper box is controlled at 130°C, and the temperature of the lower box is controlled at 190°C;

[0046] f. Embossing;

[0047] g. Rewinding, the winding tension is controlled at 6N, and the speed of the winding machine is synchronized with the speed of the unwinding machine.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap