Hinge type large-tonnage anchor device

An anchoring device and large-tonnage technology, applied in sheet pile walls, excavation, construction, etc., can solve the problems of increasing the cost of underground obstacles, wasting materials, and inconvenient construction of underground structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

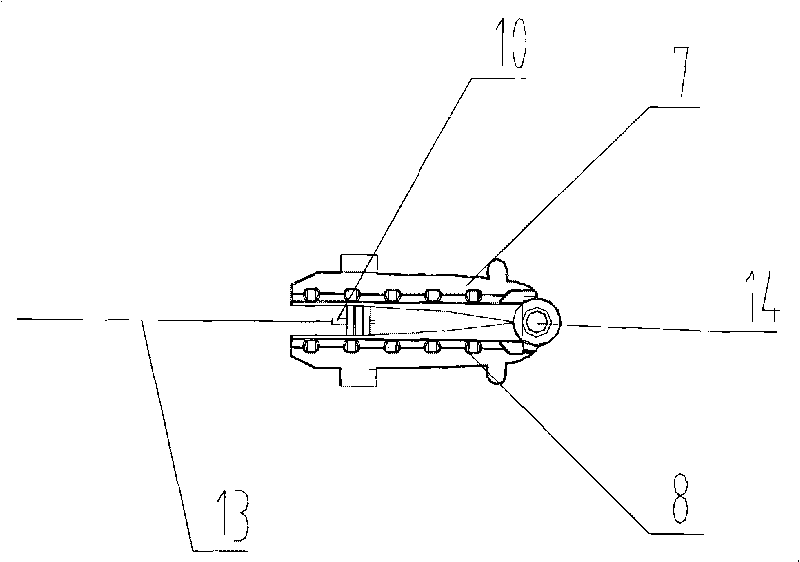

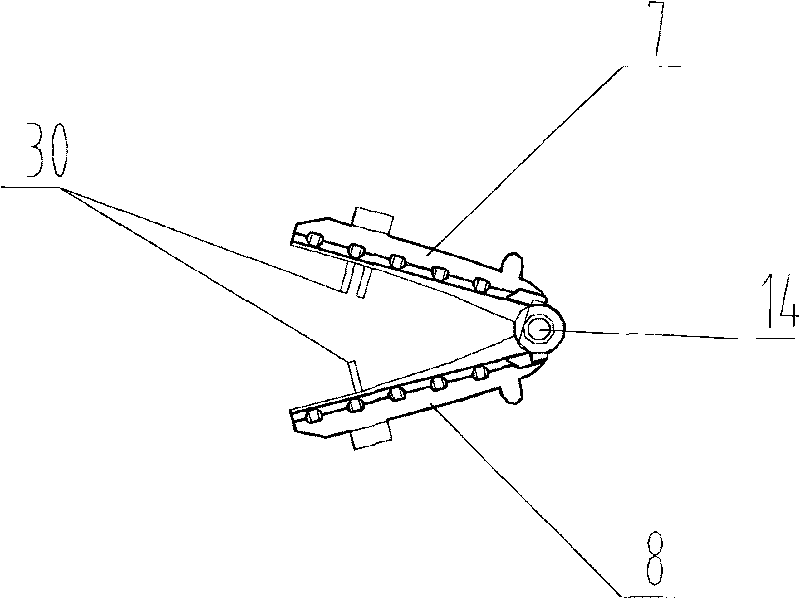

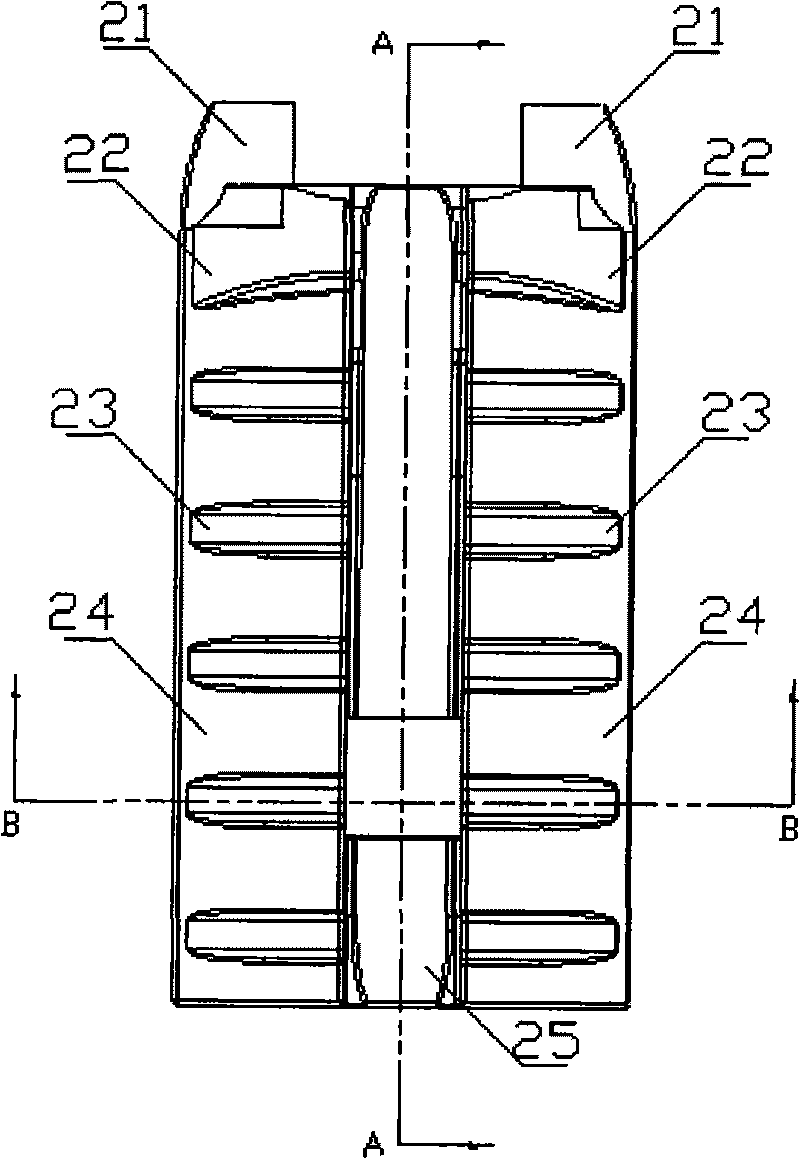

[0024] as attached Figure 1-6 A hinge-type large-tonnage anchoring device of the present invention shown includes a hinge-type large-tonnage anchoring device A7, a hinge-type large-tonnage anchoring device B8; the hinge-type large-tonnage anchoring device A7, hinge The central position of the outer surface of the large-tonnage anchoring device B8 is provided with a vertical rib 28. The vertical rib 28 is provided with a limit ring 29; the limit ring 29 is provided with a limit hole 25; the hinge type The ends of the large-tonnage anchoring device A7 and the hinge-type large-tonnage anchoring device B8 are provided with a hinge 21, and the hinge is provided with a hinge hole 26, and the spare pin 14 is inserted into the hinge hole 26 to realize the hinge-type large-tonnage anchoring The hinge connection of the device A7 and the hinge-type large-tonnage anchoring device B8 enables them to rotate relative to each other around the zero-matching bolt; All are provided with a lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com