Hydraulic pump control device for building machine

A technology for control devices and construction machinery, applied in pump control, fluid pressure actuation devices, construction, etc., can solve problems such as discomfort, reduce fuel efficiency, noise, etc., and achieve improved fuel efficiency, improved operability, and improved operability and fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a hydraulic pump control device for a construction machine according to an embodiment of the present invention will be described.

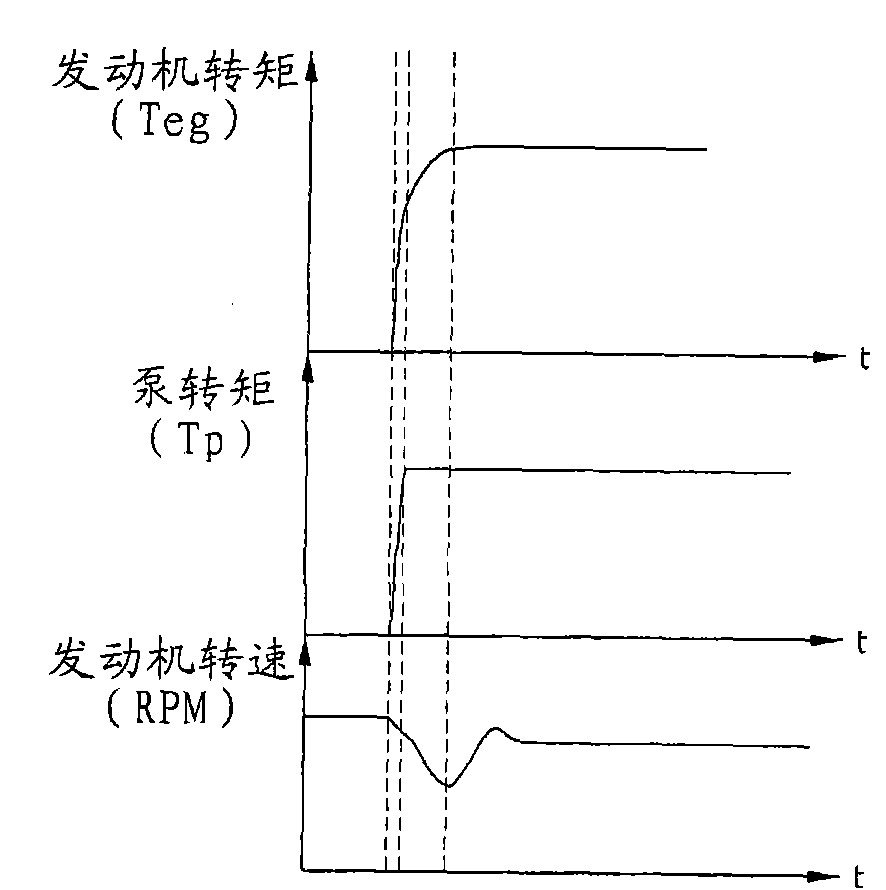

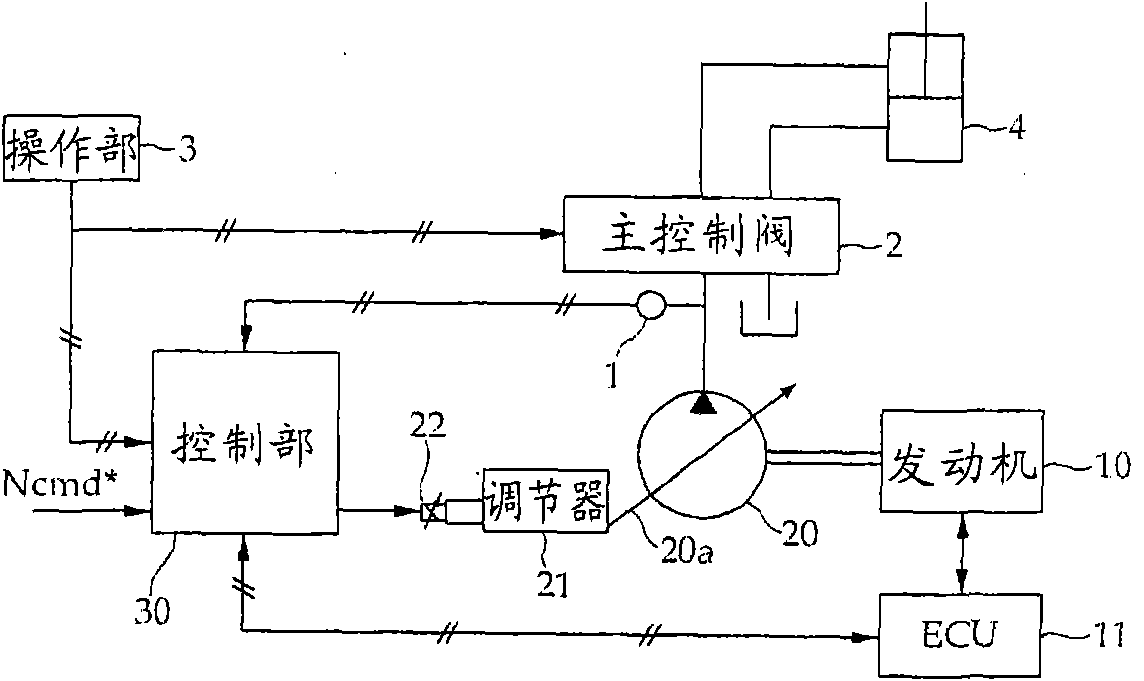

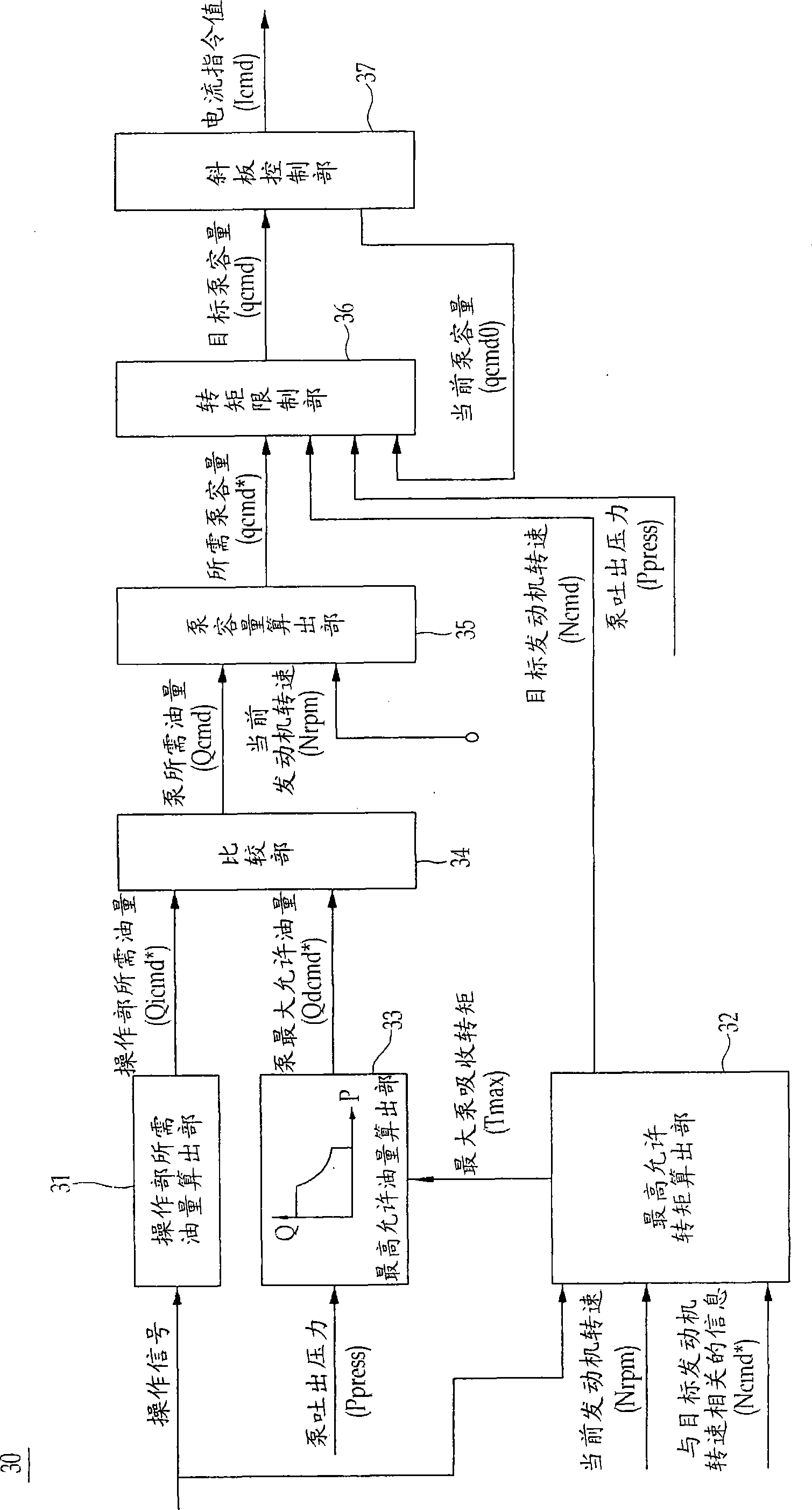

[0035] refer to figure 2 A hydraulic pump control device for a construction machine according to an embodiment of the present invention includes a control unit 30 for controlling the torque increase rate of the hydraulic pump 20 so as to correspond to the torque increase rate of the engine 10 .

[0036] Since the hydraulic pump 20 is connected to the engine 10 , the torque of the hydraulic pump 20 directly acts on the engine 10 as a load. Therefore, if the torque of the hydraulic pump 20 is too large, the rotation speed of the engine 10 may decrease, and the driving of the engine 10 may be stopped.

[0037] The above hydraulic pump 20 is provided with a swash plate 20a, and the discharge amount of oil can be changed according to the inclination angle of the swash plate 20a. Therefore, when the discharge pressure of the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com