Bearing Assembly

一种轴承装置、轴承圈的技术,应用在轴承装置领域,能够解决轴承磨损加大、轴承非圆形等问题,达到好运转的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

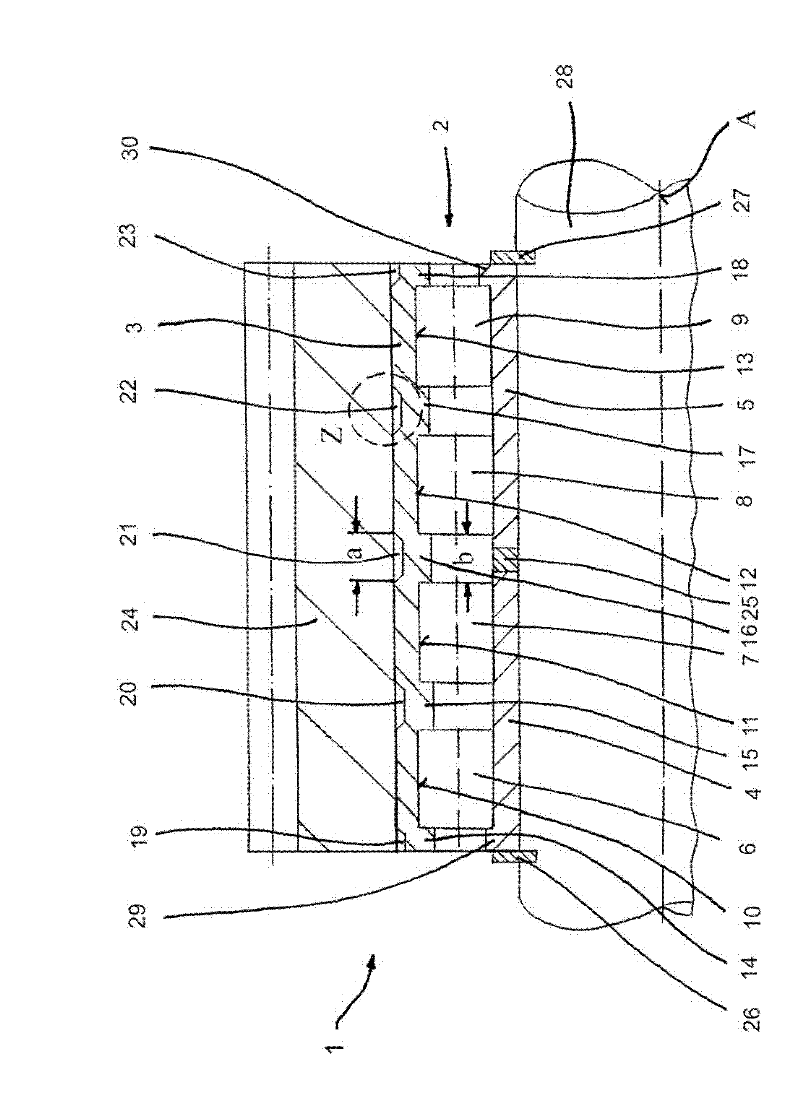

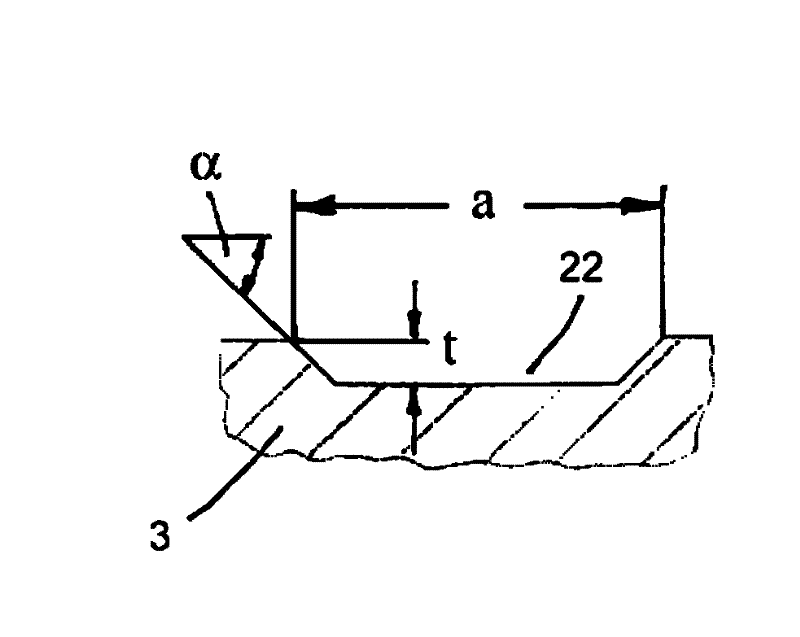

[0022] exist figure 1 The figure schematically shows a bearing arrangement 1 , by means of which a gear 24 of a planetary gear of a wind power plant is supported on a shaft 28 . Since the gear wheel 24 is a helical spur gear, axial forces also arise during operation which must be absorbed by the rolling bearing 2 of the bearing arrangement 1 .

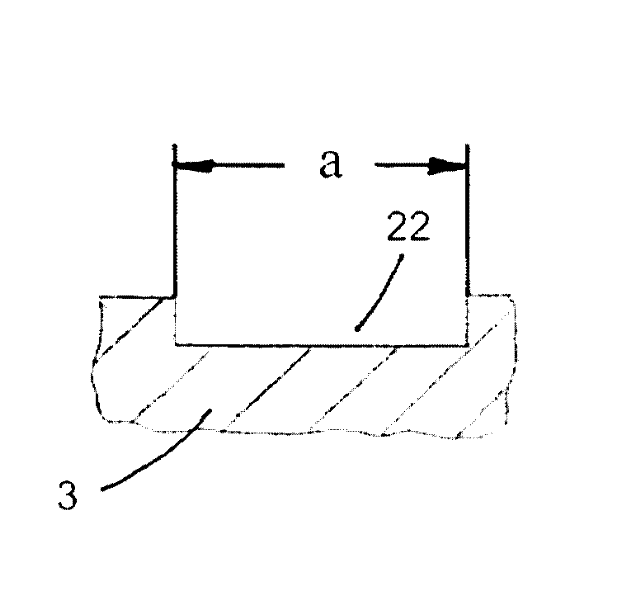

[0023] The rolling bearing 2 is designed as a four-row cylindrical roller bearing. In this case, the outer ring 3 of the bearing is designed in one piece (but this is not mandatory); A radially inwardly extending rib 15 , 16 , 17 is provided between the two raceways. Ribs 14 and 18 are located in the axial end region of outer ring 3 .

[0024] The rolling bearing 2 has two inner rings 4 and 5 with corresponding inner ring raceways. A spacer ring 25 is provided between the two inner rings 4 and 5 . Each of the two inner rings 4 , 5 has ribs 29 and 30 in the region of the axial ends of the rolling bearing 2 . Axial forces can thus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com