Pressure control valve

A technology of pressure regulation and valve body, applied in the field of pressure regulating valve, can solve the problems of increased oil consumption, complex structure, difficult manufacture, etc., and achieve the effect of reducing the number of parts, saving costs, and improving the reliability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

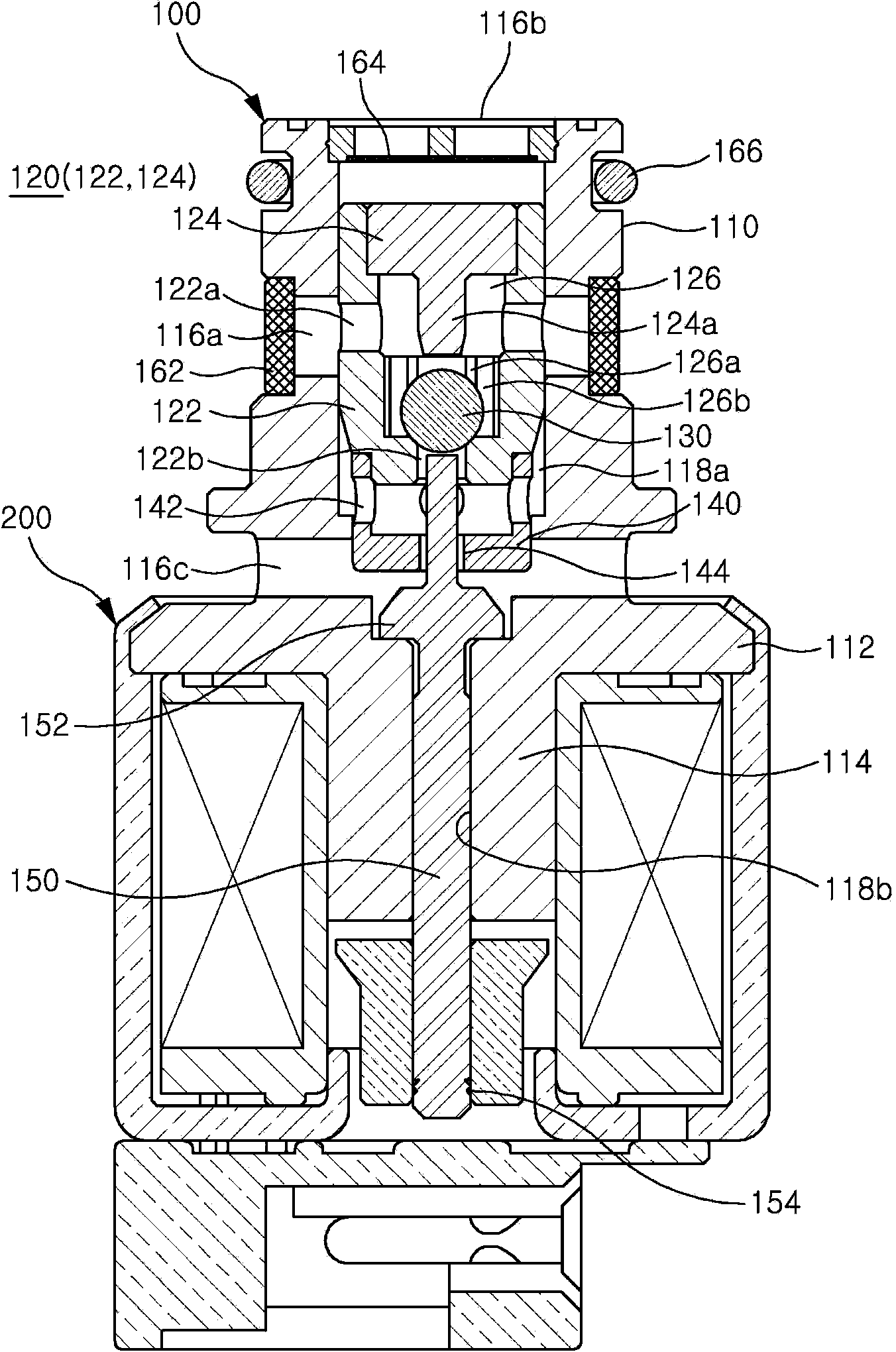

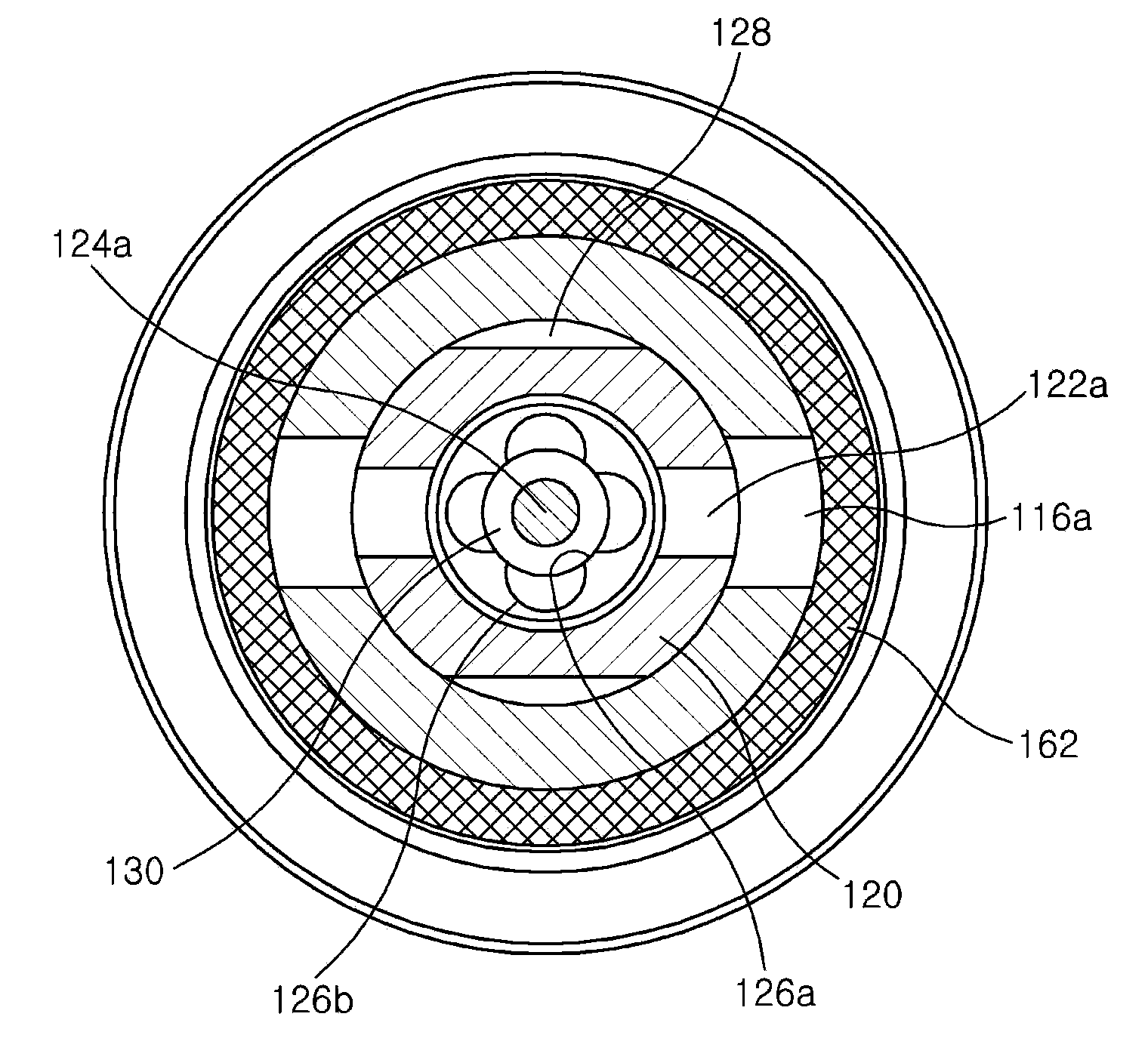

[0021] Embodiments according to the present invention will be described in detail with reference to the drawings. Hereinafter, when describing an embodiment according to the present invention and assigning reference numerals to constituent elements in each drawing, even if they appear in different drawings, the same constituent elements are assigned the same numerals as much as possible.

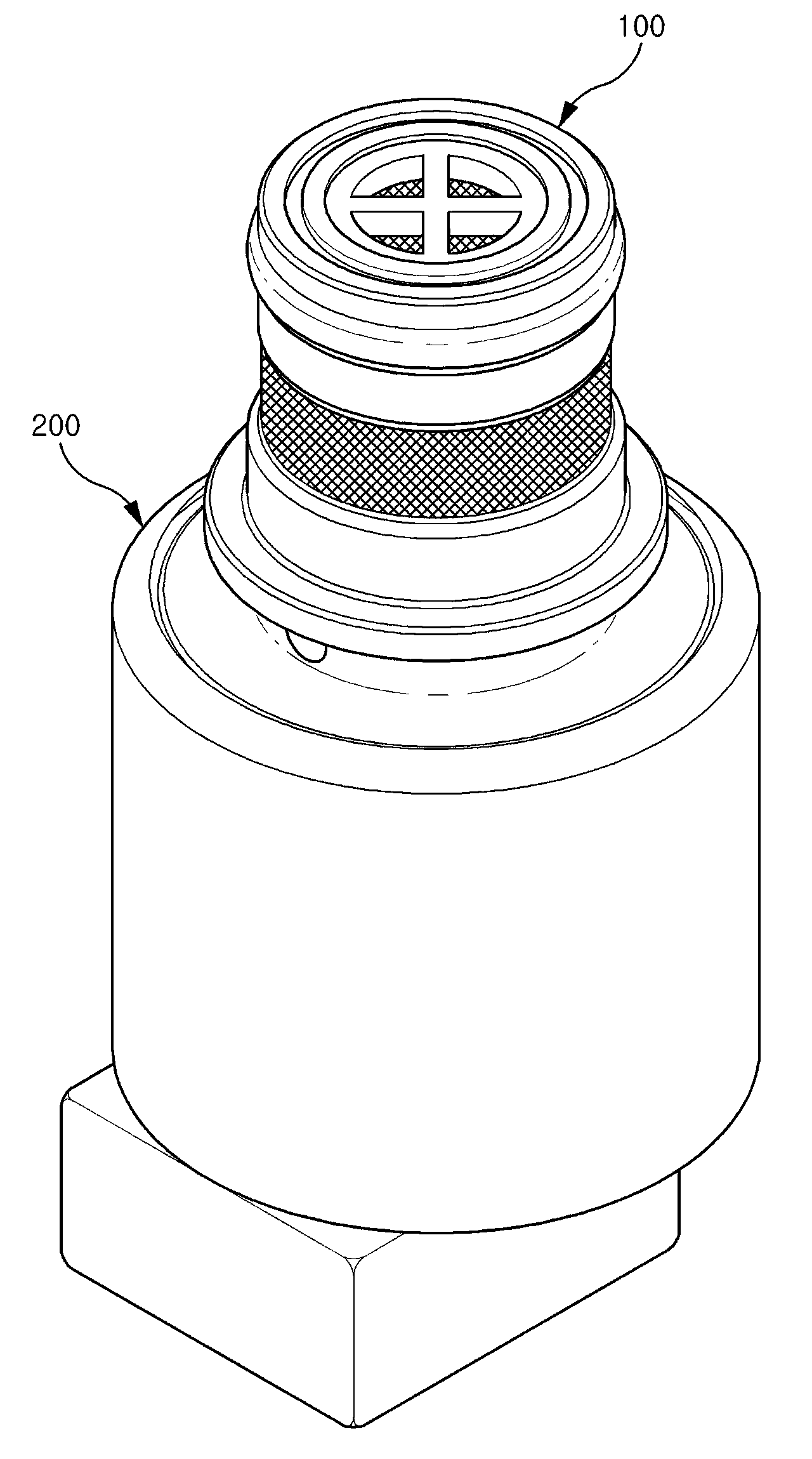

[0022] figure 1 It is an oblique view of a pressure regulating valve according to an embodiment of the present invention.

[0023] Such as figure 1 As shown, according to the pressure regulating valve of this embodiment, the valve portion 100 supplied to the clutch side by applying a certain regulation pressure to the fluid supplied from the outside and adjusting the opening amount of the valve portion 100 according to the value of the current applied from the outside Thus, the electromagnetic part 200 for adjusting the adjustment pressure is constituted.

[0024] refer to Figure 2 to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com