Scroll compressor

A technology for scroll compressors and compressor housings, which is applied to rotary piston machinery, rotary piston pumps, mechanical equipment, etc., and can solve the problems of increased axial clearance, increased vibration, and unstable movement of the cross ring. problems, to avoid leakage, reduce the effect of starting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

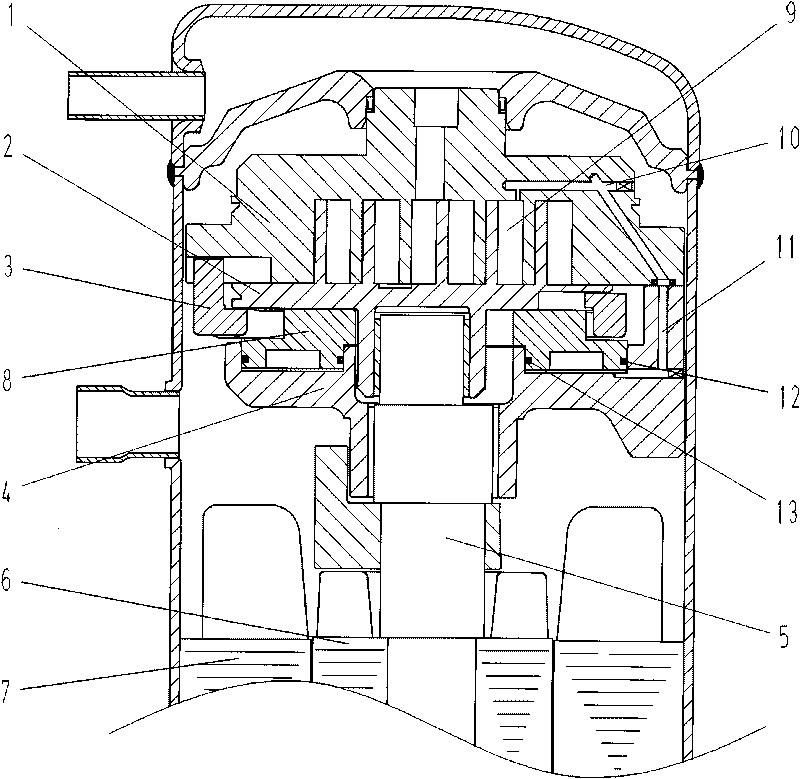

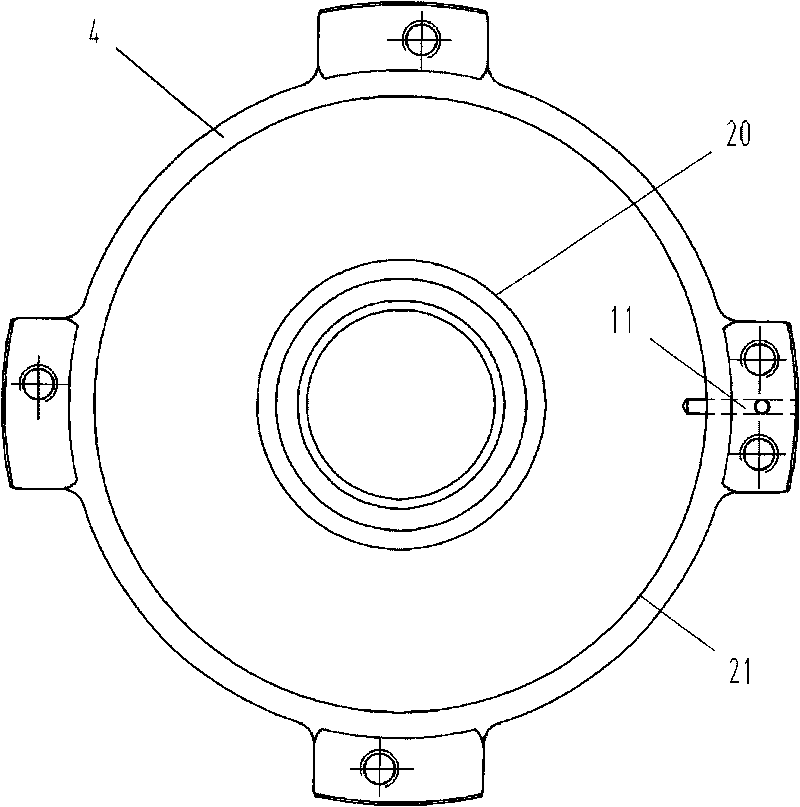

[0025] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings. Such as figure 1 As shown, the scroll compressor mainly includes a fixed scroll 1 , a movable scroll 2 , an Oldham ring 3 , an upper support 4 , a crankshaft 5 , a motor rotor 6 , and a motor stator 7 . The fixed scroll 1 and the movable scroll 2 cooperate to form a plurality of compression chambers 9, and the cross ring 3 is arranged on the back side of the movable scroll 2 to cooperate with the fixed scroll 1 and the movable scroll 2, so that the movable scroll 2 can only be opposite to each other. The fixed scroll 1 moves in translation, the crankshaft 5 is driven by the motor stator 7 through the motor rotor 6, and the crankshaft 5 drives the movable scroll 2 to move along the orbital plane, thereby completing the suction, compression and exhaust process of the compressed working medium.

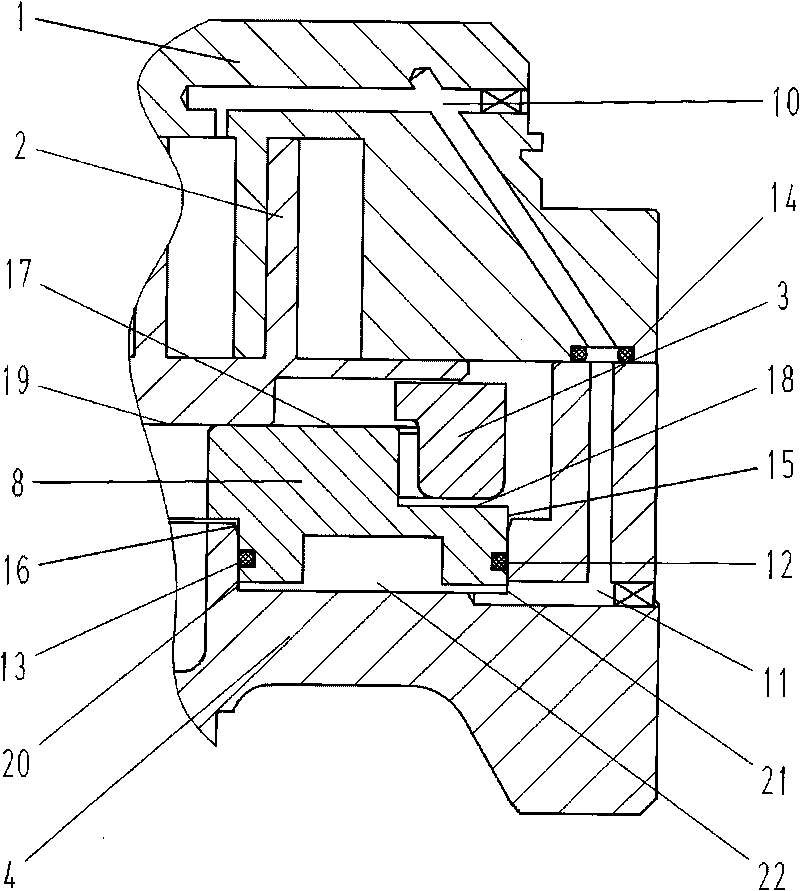

[0026] Such as figure 2 As shown, a floating disc 8 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com