Special improved single-rod hanger for cable tray

A technology for cable trays and hangers, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as delay in construction period, inconvenience in construction, and increase in difficulty, and achieve convenient and accurate installation, convenient adjustment, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

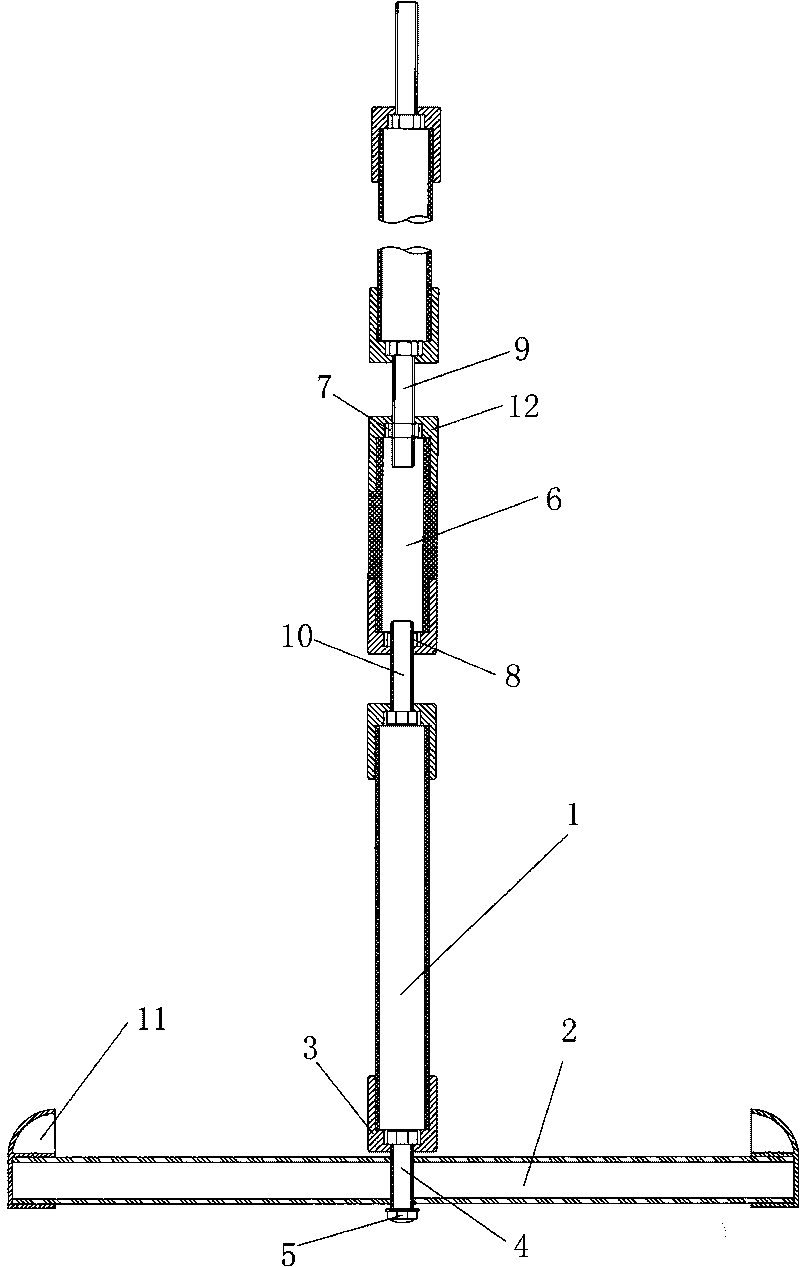

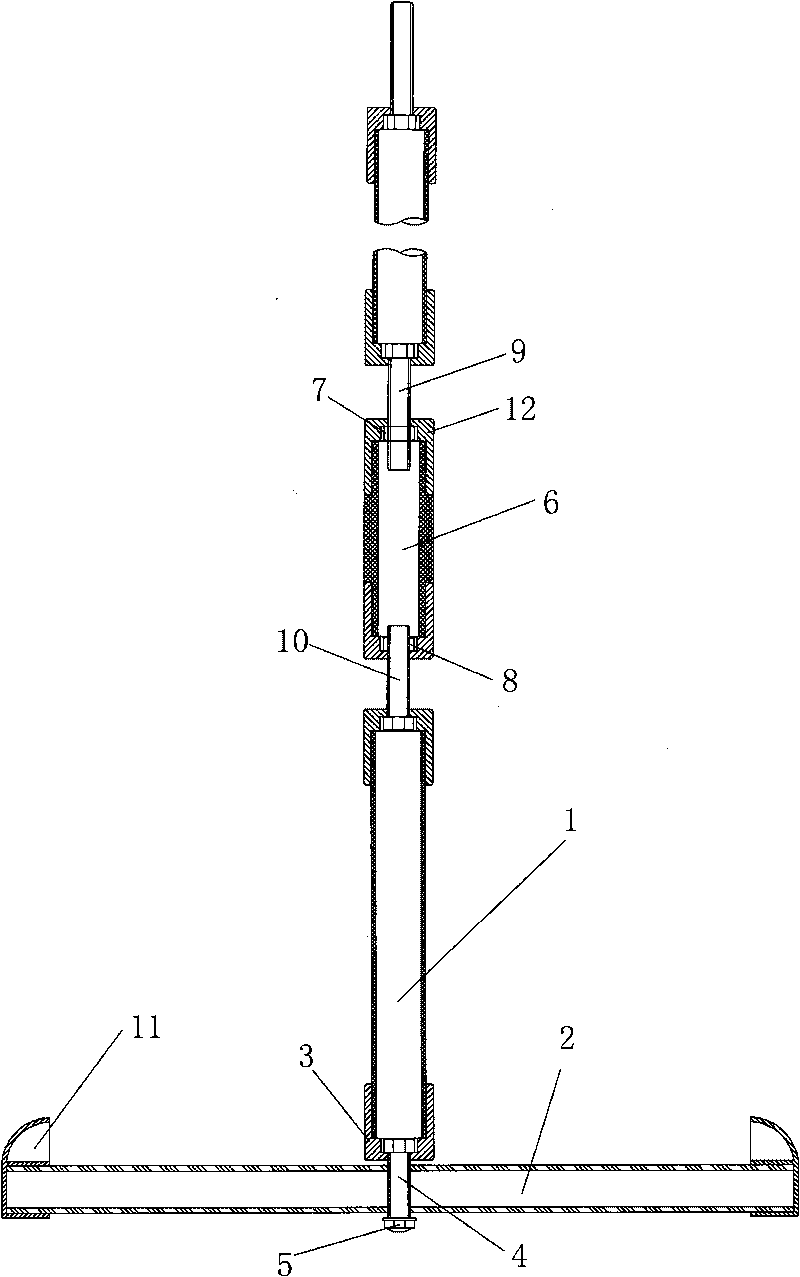

[0013] Embodiment: An improved single-rod hanger dedicated to a cable bridge, including a hanger 1 and a supporting plate 2. Based on the use direction of the hanger, the upper end of the hanger is fixedly connected to the steel beam. The hanger is one, and there is a The hollow first fixing part 3 has a radial baffle plate formed on the bottom of the first fixing part, and a hole is opened on the baffle plate, and the first bolt 4 is inserted in the hole, and the big end of the first bolt stops against the baffle plate, And it is locked with the first fixing part. The first fixing part is fixedly set on the lower end of the boom. In actual installation, the first bolt can be added to the first fixing part first, and glue can be added to connect the first fixing part with the boom. The lower end is glued and assembled into pieces, the middle part of the supporting plate is provided with a perforation, the lower end of the bolt passes through the perforation and passes out of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap