A shift register circuit having threshold voltage compensation

A shift register and threshold voltage technology, applied in static memory, digital memory information, instruments, etc., can solve problems such as transistor performance degradation and limited circuit life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

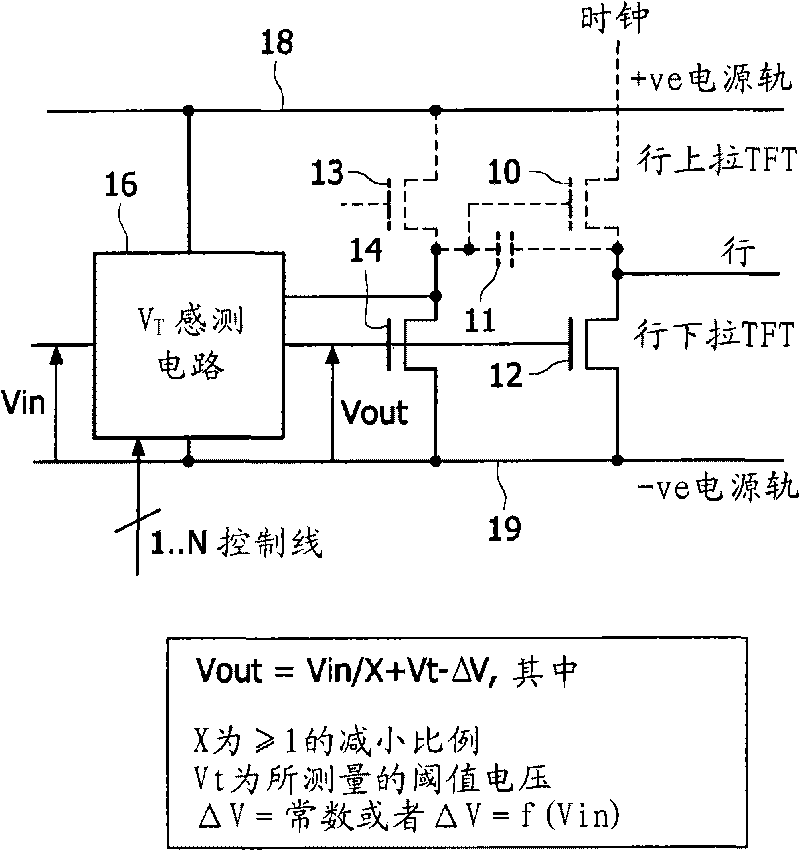

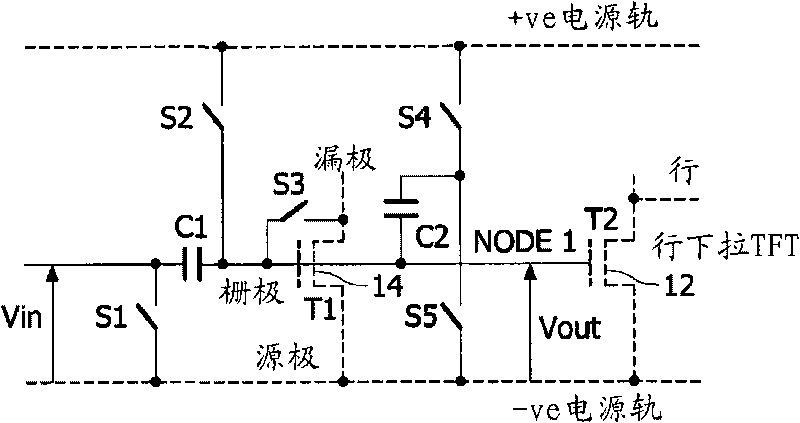

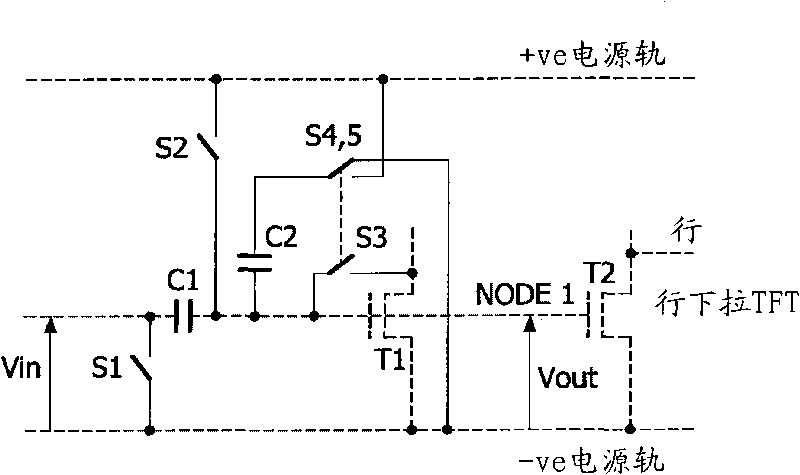

[0060] figure 1 A first simplified example of the inventive circuit is shown to illustrate the principles of the invention.

[0061] The present invention provides sensing of the threshold voltage of the most critical transistor or transistors in the circuit. The row driver circuit has: a row pull-up transistor 10, which is turned on to provide a row pulse on the row from the clocked power supply line "CLOCK"; and a row pull-down transistor 12, which is used on the remaining Time keeps the row at a low negative power rail voltage. Row pull-down transistor 12 operates at a high duty cycle and therefore suffers from the greatest drift.

[0062] In one example, the present invention provides threshold voltage sensing of the row pull-down transistor 12 . The sensing circuit may use thin film transistors (TFTs) of the row driver circuit, or it may use dedicated TFTs designed to match the characteristics of the TFT being compensated.

[0063] figure 1 Transistor 14 for replicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com