Automatic bending machine for inflating valve

A valve and automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unstable processing quality, unsafety, large pin shaft force, etc., and achieve stable and reliable product quality and high degree of automation , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

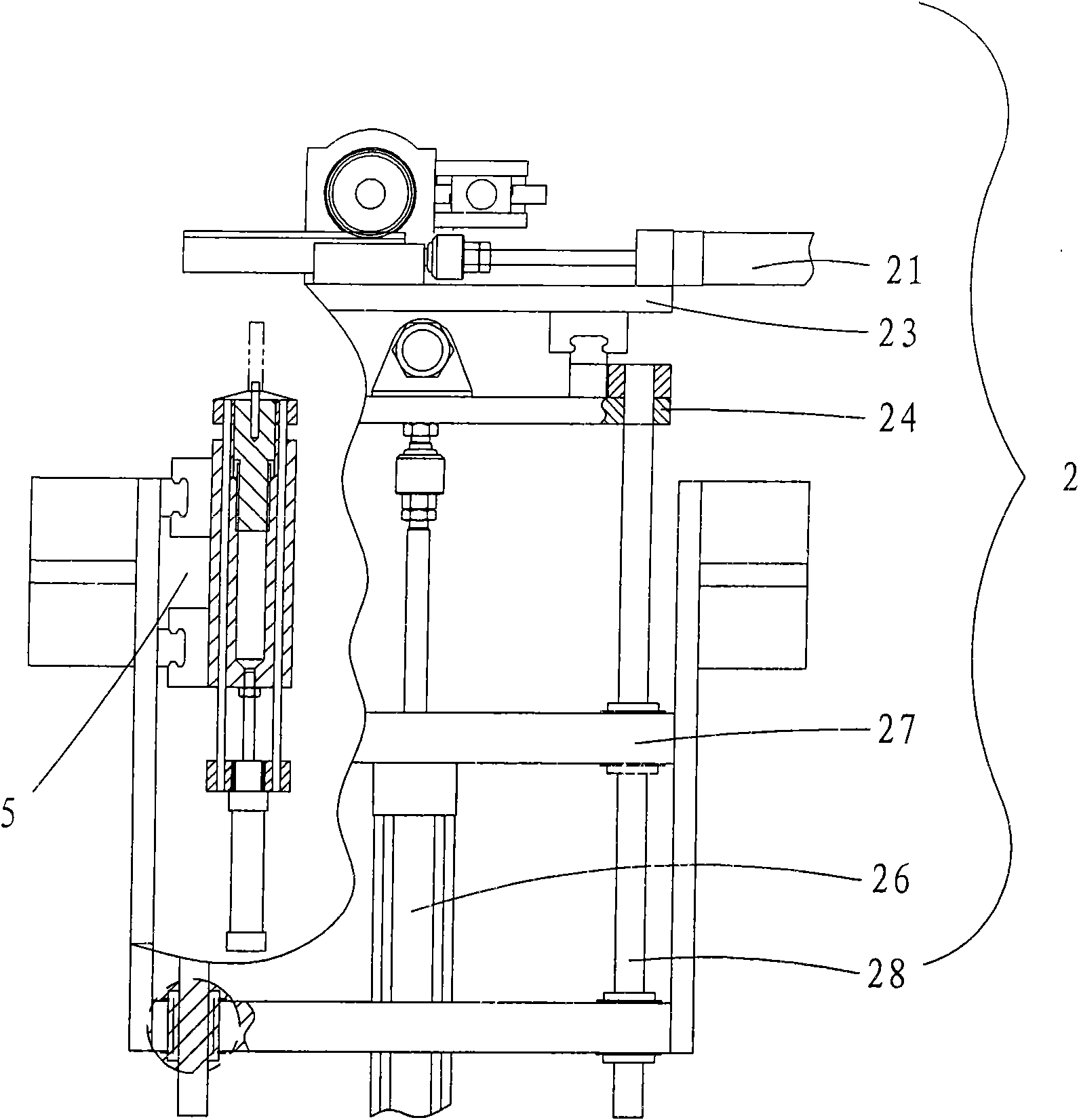

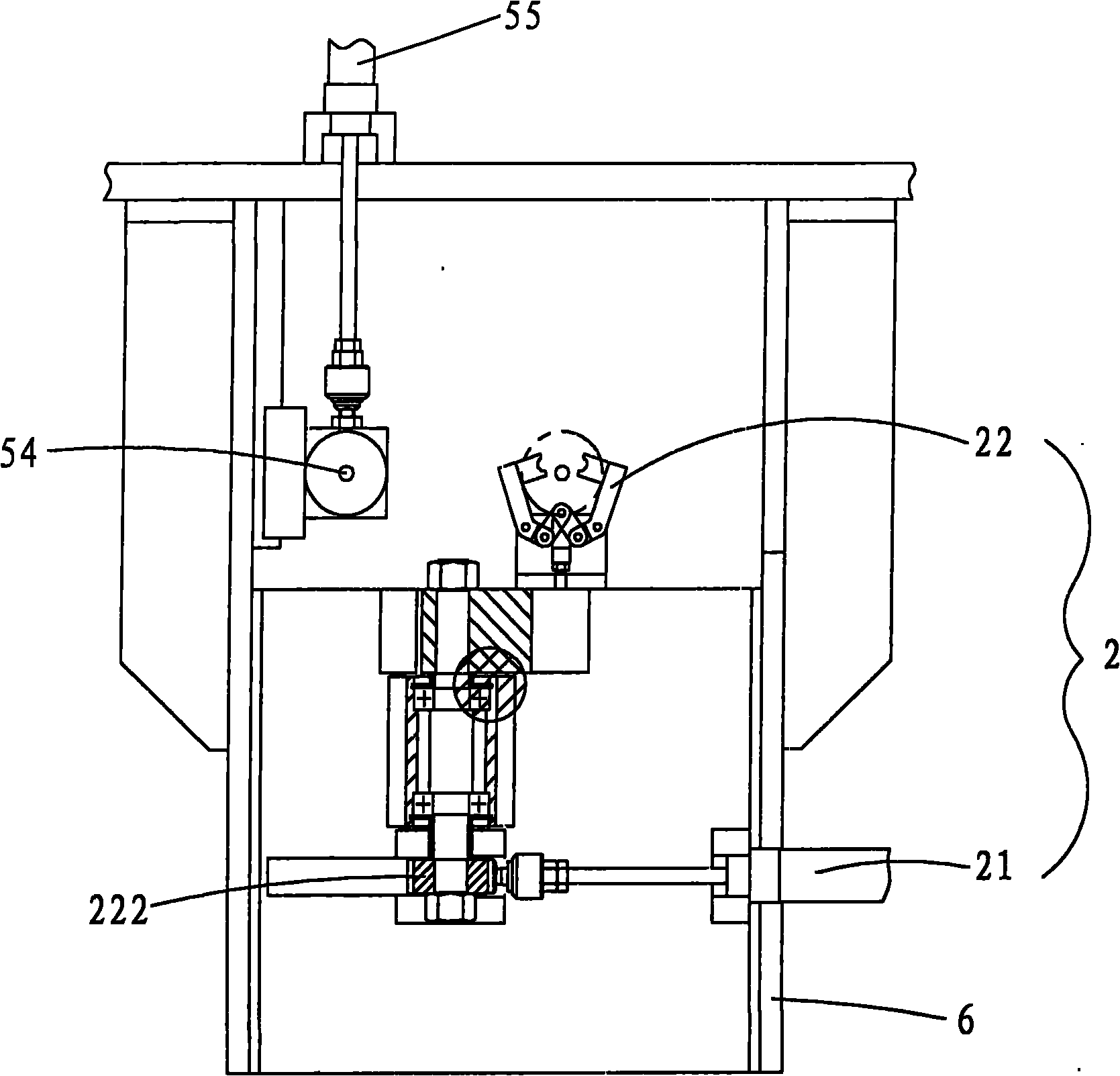

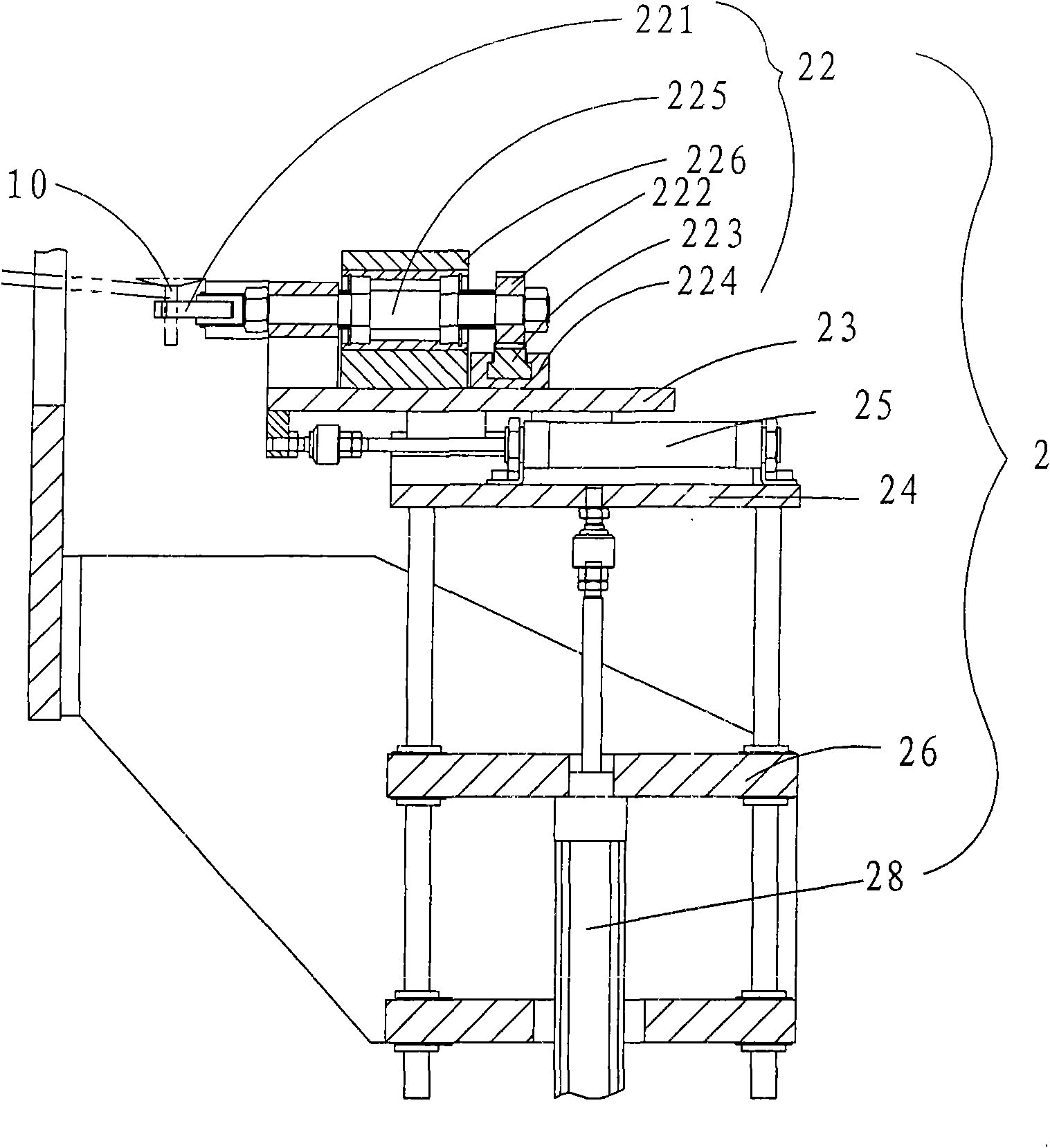

[0021] Such as figure 1 refer to figure 2 , image 3 As shown, the present invention is an automatic valve bending machine, which is mainly composed of a feeding tray 1, a feeding mechanism 2, a clamping and positioning mechanism 3, a bending mechanism 4, a material returning mechanism 5 and a frame 6.

[0022] The feeding mechanism 2 is installed on the frame 6 and the pneumatic finger 221 on it is located below the feeding tray 1; the clamping positioning mechanism 3 is installed on the frame 6 and the clamps 33 on it are aligned The feeding block 54 of the material return mechanism is so as to clamp the workpiece; the described material return mechanism 5 is installed on the frame 6 and the feeding block 54 on it is located at the end point of the running track line of the pneumatic finger 221 of the feeding mechanism 2, so as to accommodate Valve 10.

[0023] Described feeding mechanism 2 comprises clamping cylinder 21, clamping mechanism 22, front and rear sliding pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com