Flat knitting machine for knitting cylindrical knitted fabric and method of knitting cylindrical knitted fabric

A technology for knitted fabrics and tubular shapes, which is applied in the field of flat knitting machines for knitting tubular knitted fabrics and the field of knitting tubular knitted fabrics. It can solve the problems of easy penetration of material liquid into the interior and uneven thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

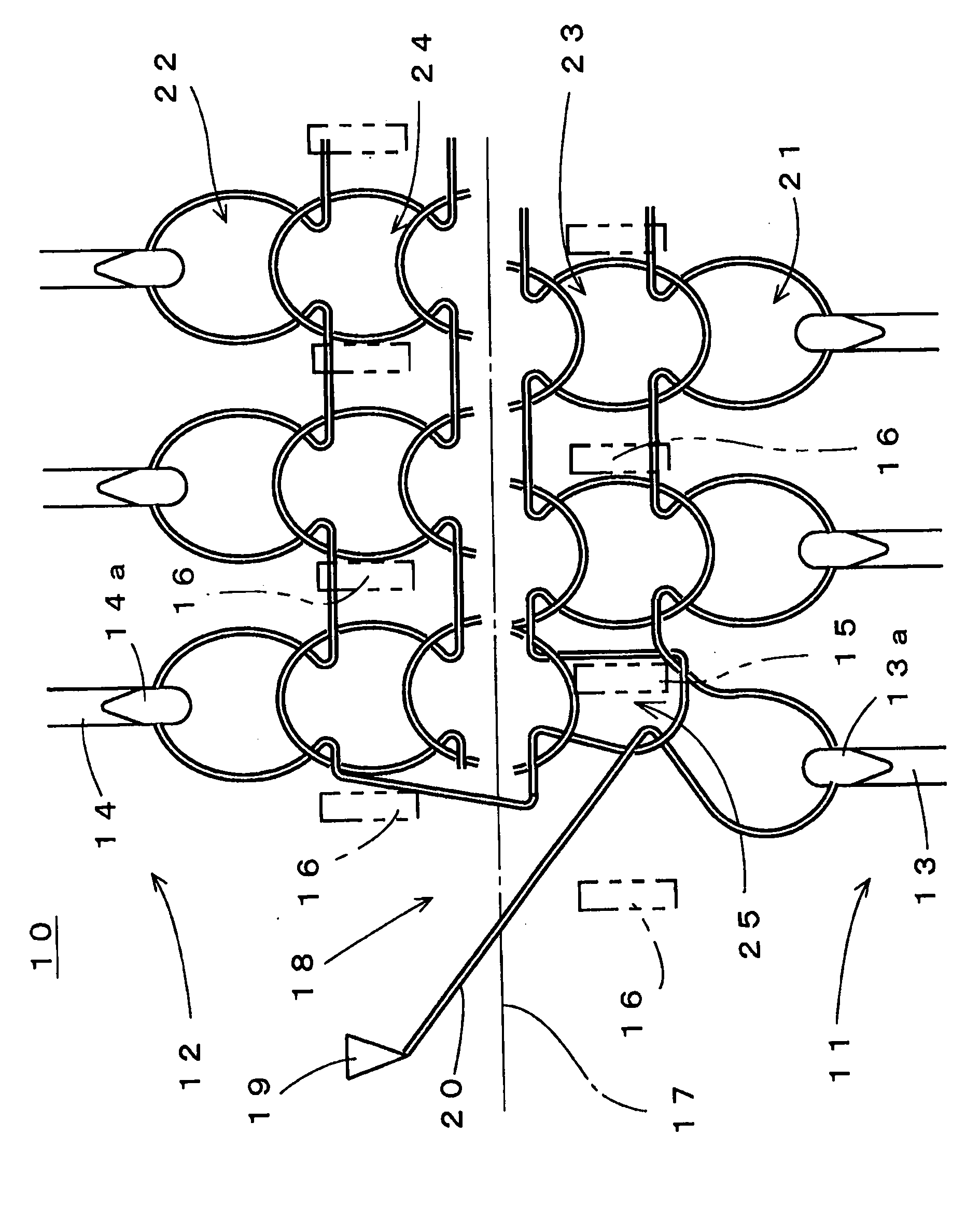

[0048] figure 1 The principal parts of the configuration of the flat knitting machine 10 according to one embodiment of the present invention are schematically shown. The flat knitting machine 10 has a front needle bed 11 and a rear needle bed 12 . On the front needle bed 11 and the rear needle bed 12, a plurality of knitting needles 13, 14 are arranged in line, respectively. At the tip of each knitting needle 13, 14, hooks 13a, 14a are provided. The knitting needles 13 of the front needle bed 11 and the knitting needles 14 of the rear needle bed 12 are arranged so that the positions where they meet are shifted. Tubular knitted fabrics are woven by feeding yarns in such a way that the knitting yarns go around in a certain direction. For example, in the case of knitting a tubular knitted fabric by feeding yarn in the clockwise direction, feed the yarn from right to left in the figure to the knitting needles 13 of the front needle bed 11 and feed the yarn to the knitting nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com