Method for lifting, hanging and installing frames of anti-vibration device for buildings

An installation method and shock absorber technology, which are applied to the processing of building materials, building components, and earthquake resistance, can solve problems such as complex structures and difficulty in meeting construction requirements, and achieve large hanging body quality, satisfactory installation effects, and easy installation high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for jacking up and hanging a shock absorber frame for a high-rise building, including installing a counterweight support, installing a frame, connecting a frame, hanging a frame, hanging a counterweight, removing a counterweight support, installing a counterweight, and installing a central Mandrel, the specific steps are:

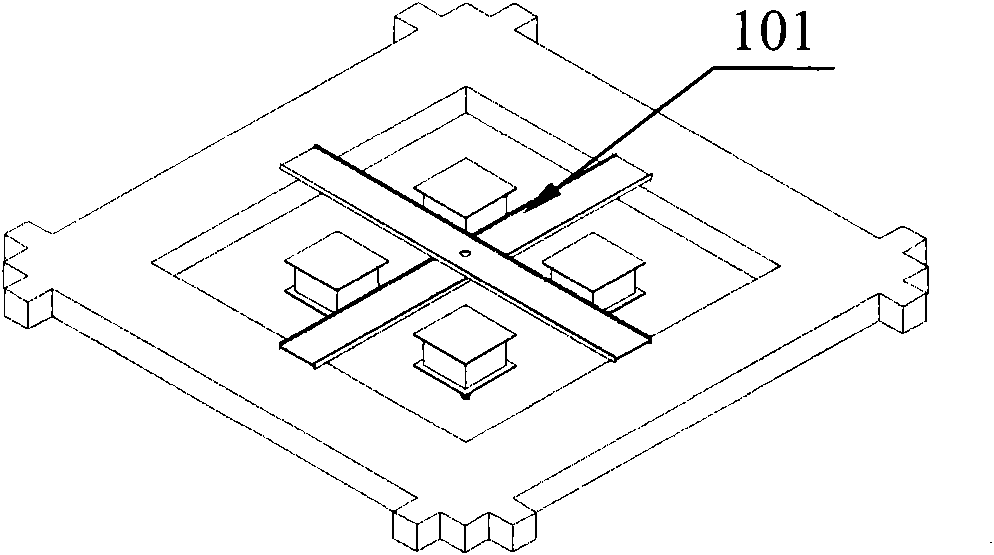

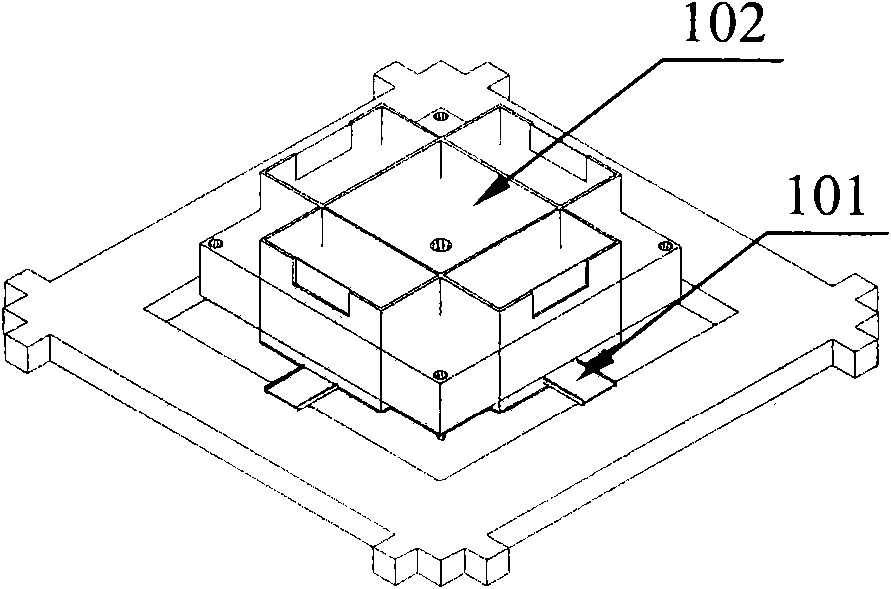

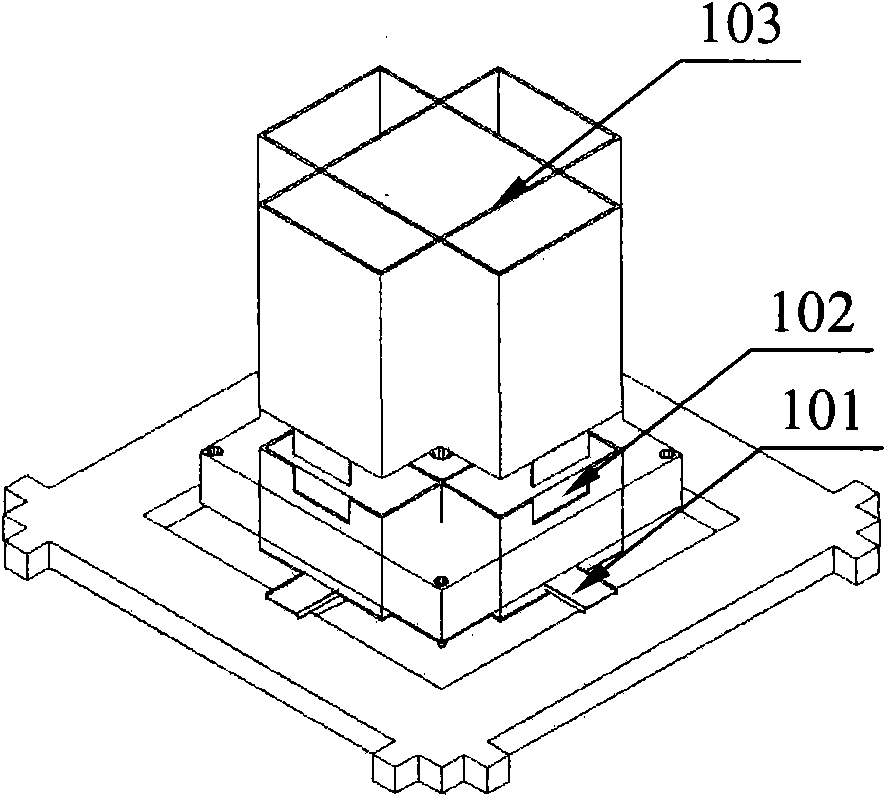

[0032] Installing the counterweight body support includes installing the counterweight body support 101, installing the counterweight body base 102 and installing the counterweight frame 103; the steps are: first four counterweight body supports 101 are installed on the foundation, such as figure 1 shown; then the counterweight base 102 is bolted and fastened to the four counterweight supports to form an integrated support body, as figure 2 Shown; Then the counterweight frame 103 is installed together with the lower part of the installed support body with bolts, and fastened, as image 3 As shown; the upper part of the support body has a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com