Explosion proof aluminous shell stamping forming die of capacitor

A technology of stamping forming and capacitors, which is applied in the field of stamping process equipment manufacturing to achieve the effect of avoiding waste and solving the accuracy and error of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

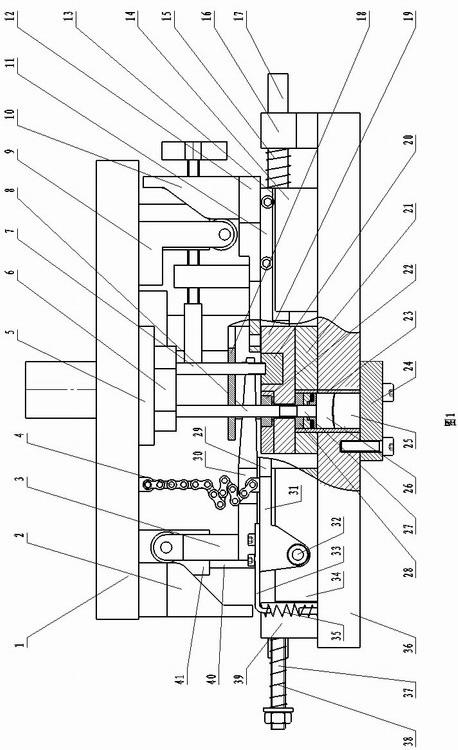

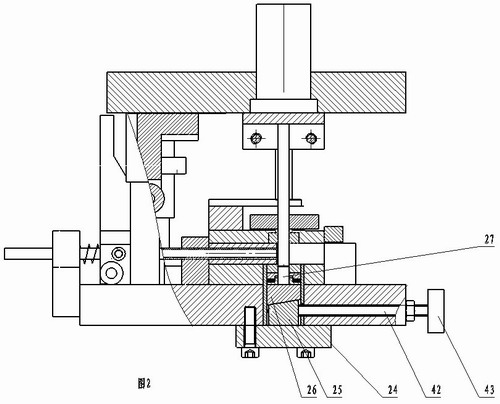

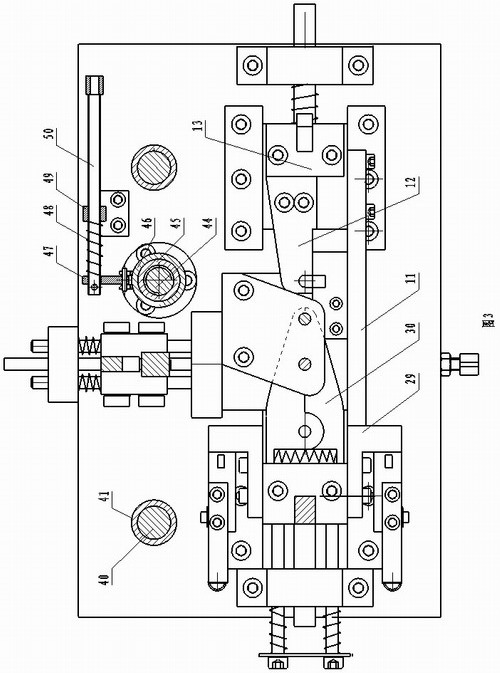

[0013] Below in conjunction with accompanying drawing example the present invention is described in further detail: figure 1 The stamping mold for explosion-proof aluminum shell of the capacitor shown has an upper template 1 and a lower template 36 for connecting with the stamping machine tool, a guide sleeve 41 is installed under the upper template 1, and a guide column 40 is installed above the lower template 36 , the guide column 40 is inserted into the guide sleeve 41, and there are two sets of connection components between the guide column and the guide sleeve. These two sets of guide columns and guide sleeves ensure the precise correspondence between the positions of the upper formwork and the lower formwork in the horizontal direction (Such as image 3 shown).

[0014] The following of the upper template 1 is equipped with a stretching punch 7 and a press punch 8 through the mounting plate 6 and the backing plate 5, and the upper template 36 is equipped with a stretchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com