Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, rolling resistance optimization, etc. It can solve the problems of radio wave obstacles, increased tire resistance, and high electrical insulation, so as to prevent static electricity accumulation and ensure electrical conductivity. , The effect of improving low rolling resistance performance and high-speed durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

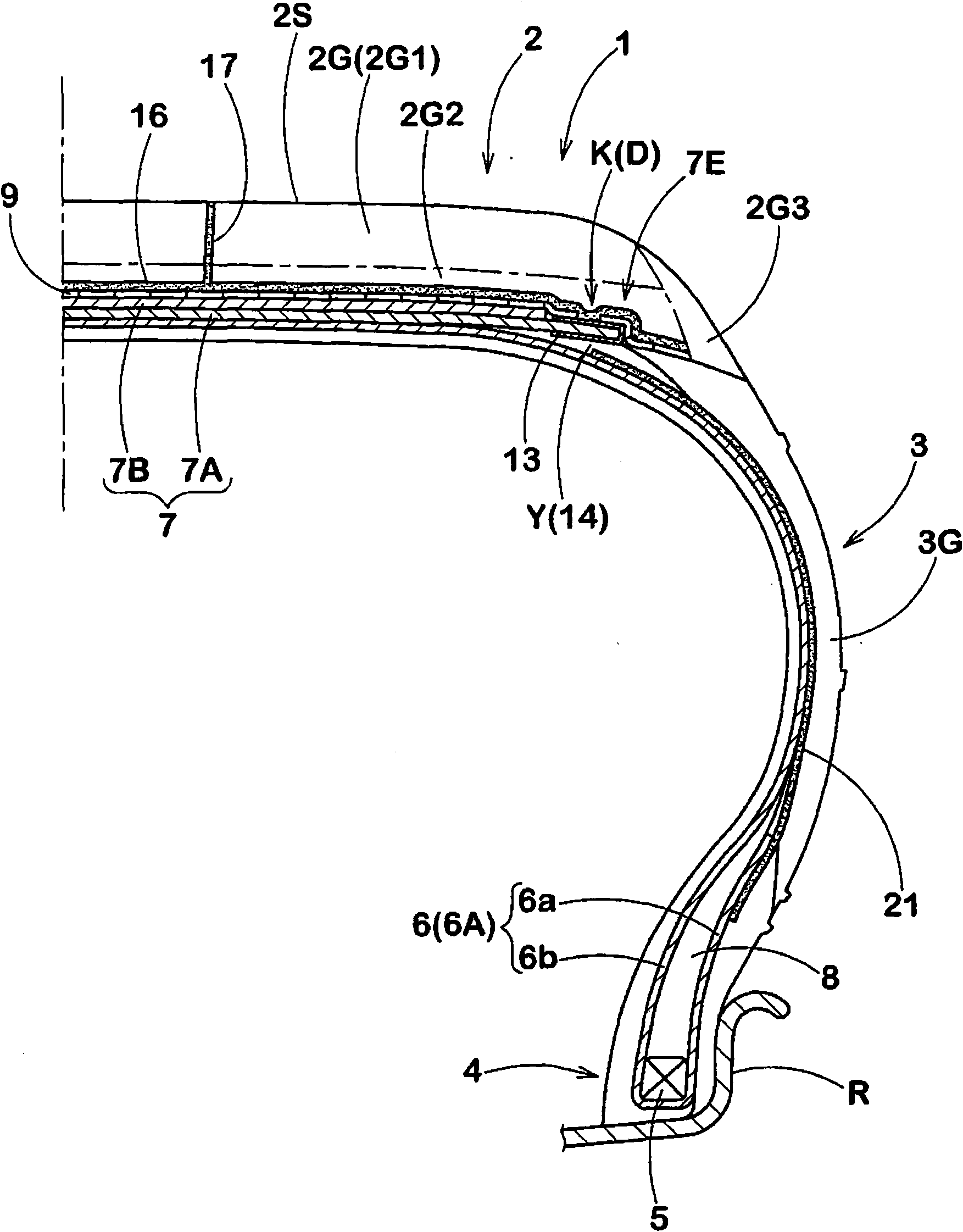

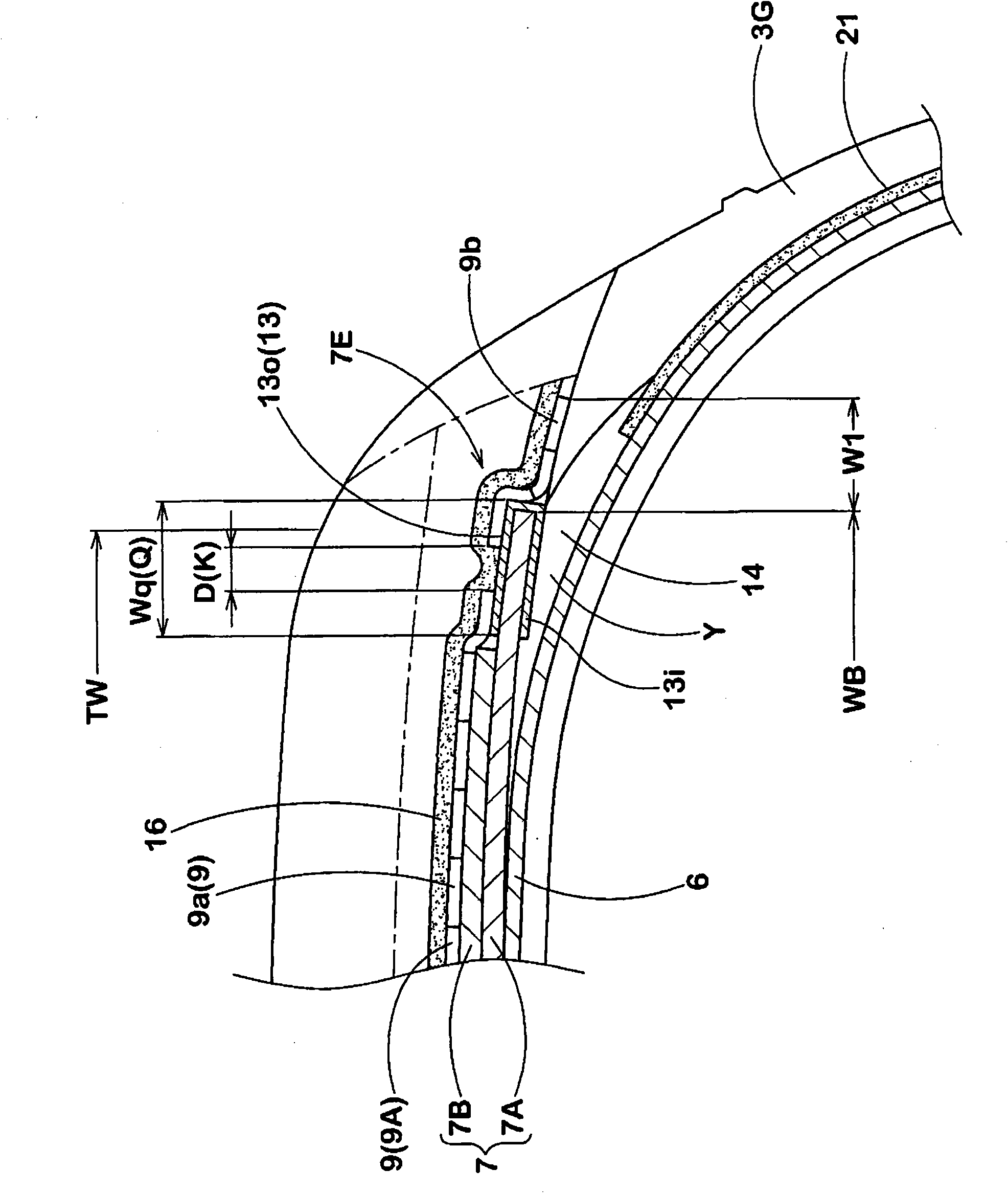

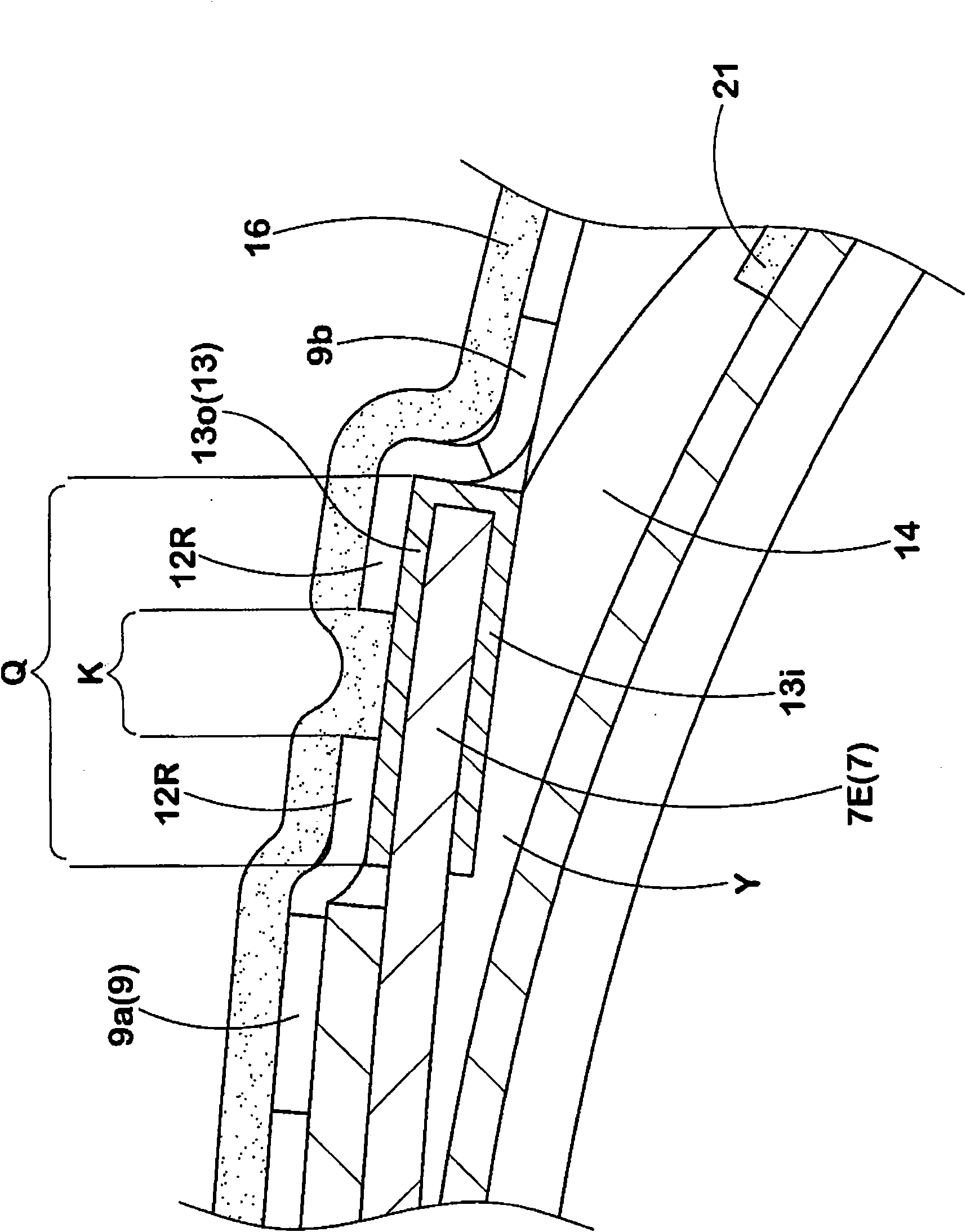

[0061] Prototype has figure 1 The basic structure of the pneumatic tire (model 195 / 65R15), the high-speed durability and resistance of each test tire were measured, and the results are shown in Table 1. In addition, the structures of the tread ends of Comparative Example 1 and Comparative Example 2 are shown in FIGS. 8(A) and (B). Except for the specifications listed in the table, the other specifications are actually the same.

[0062] In addition, only the terminal part, tread base rubber, end outer cover rubber, buffer rubber, lap joint rubber and inner conductive rubber layer use a volume intrinsic resistance of less than 1×10 5 Conductive rubber material of Ωcm, other rubber materials use a volume intrinsic resistance of 1.0×10 8 Insulating rubber material above Ωcm.

[0063] The tape width Ws of the tape tape was 10.0 mm, and the width Wq of the overlapping area Q of the end cover tape was 25.0 mm.

[0064]

[0065] use as Figure 7 Shown, contains and is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com