Drying control method for water-saving washing machine to realize just-in-time (JIT) stop after drying clothes

A drying control and washing machine technology, applied in the field of washing machines, can solve the problems of large consumption of cooling water, low heat exchange efficiency, inability to distinguish whether clothes are dry or not, and achieve the effects of improving condensation efficiency and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

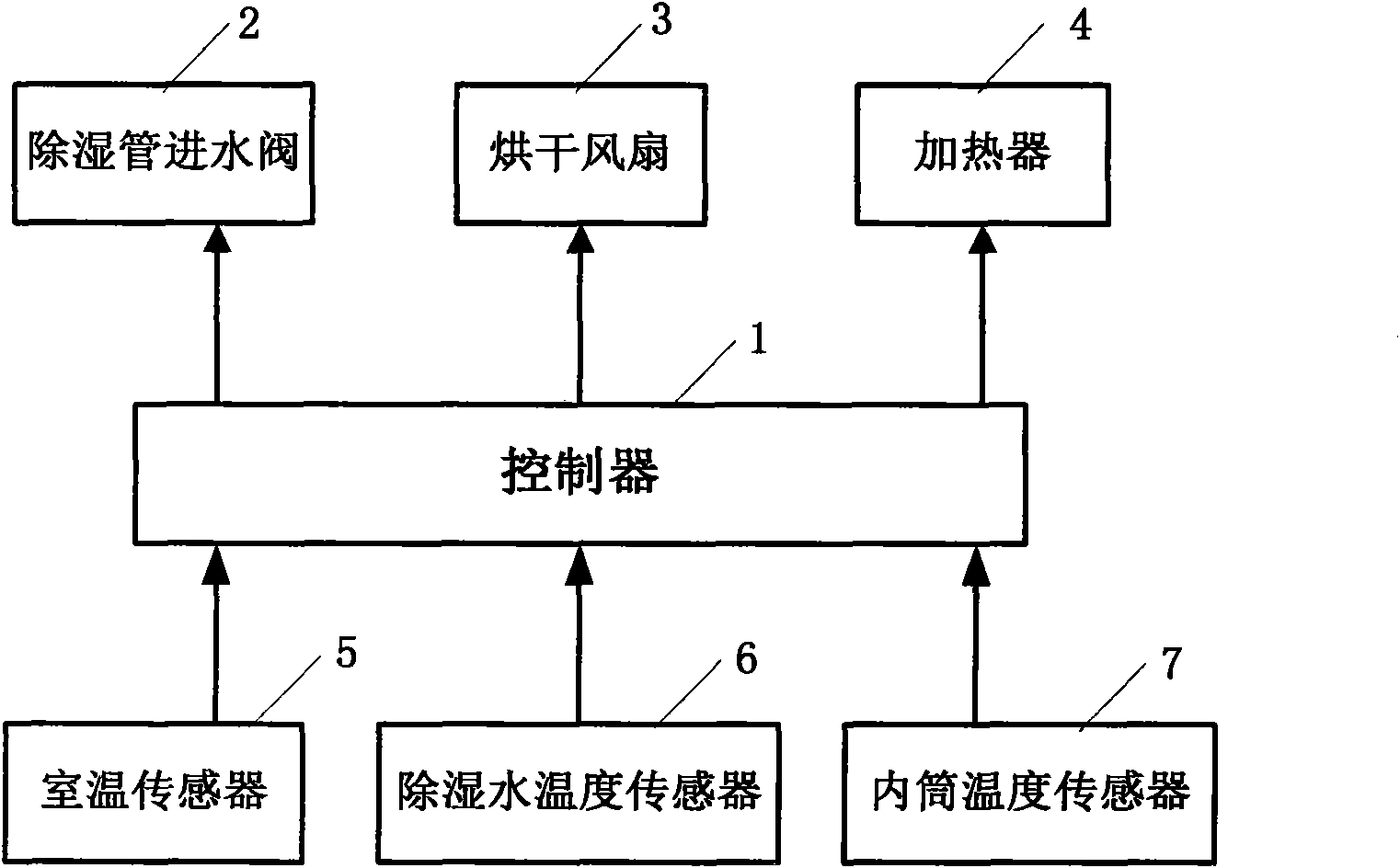

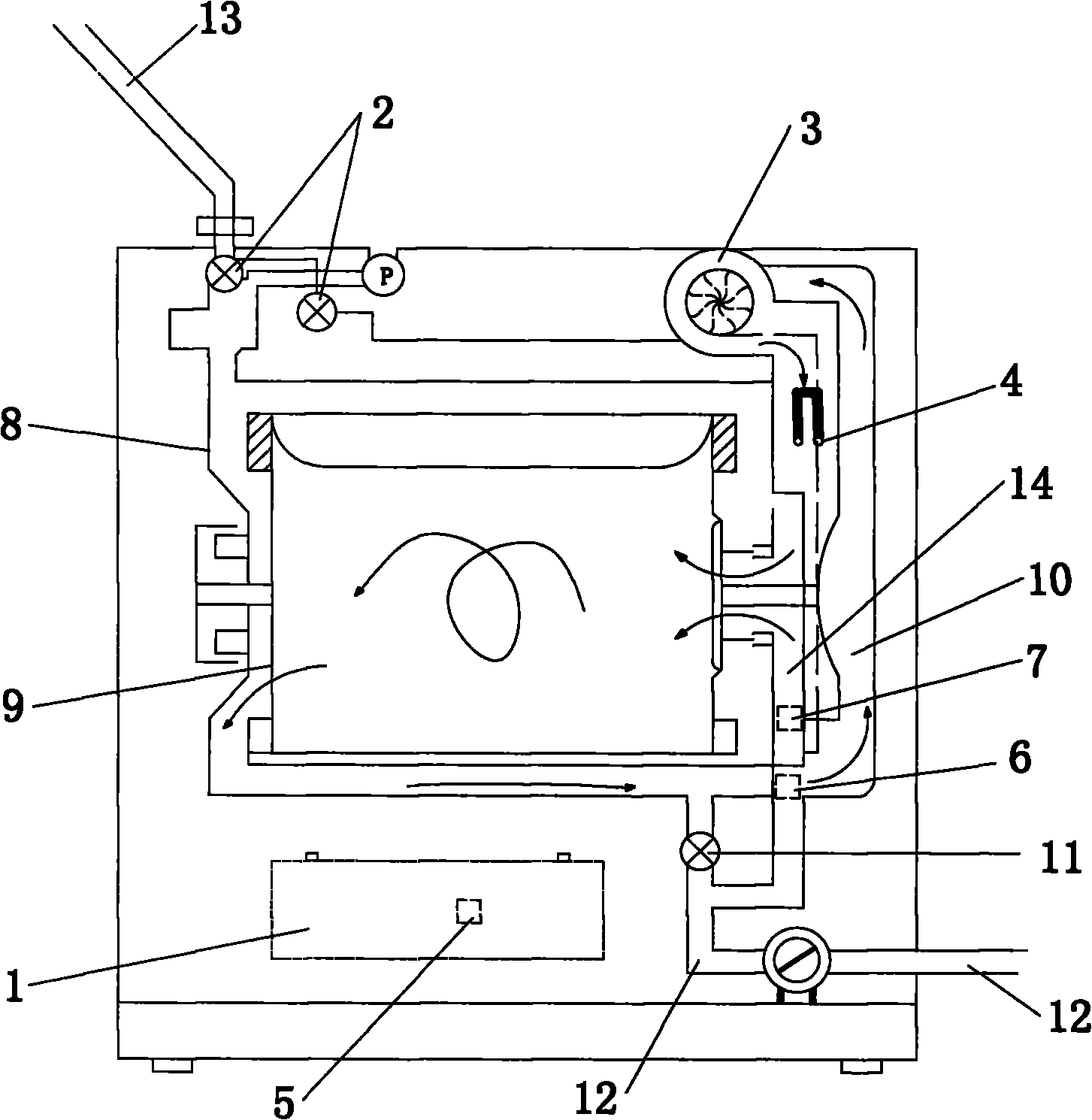

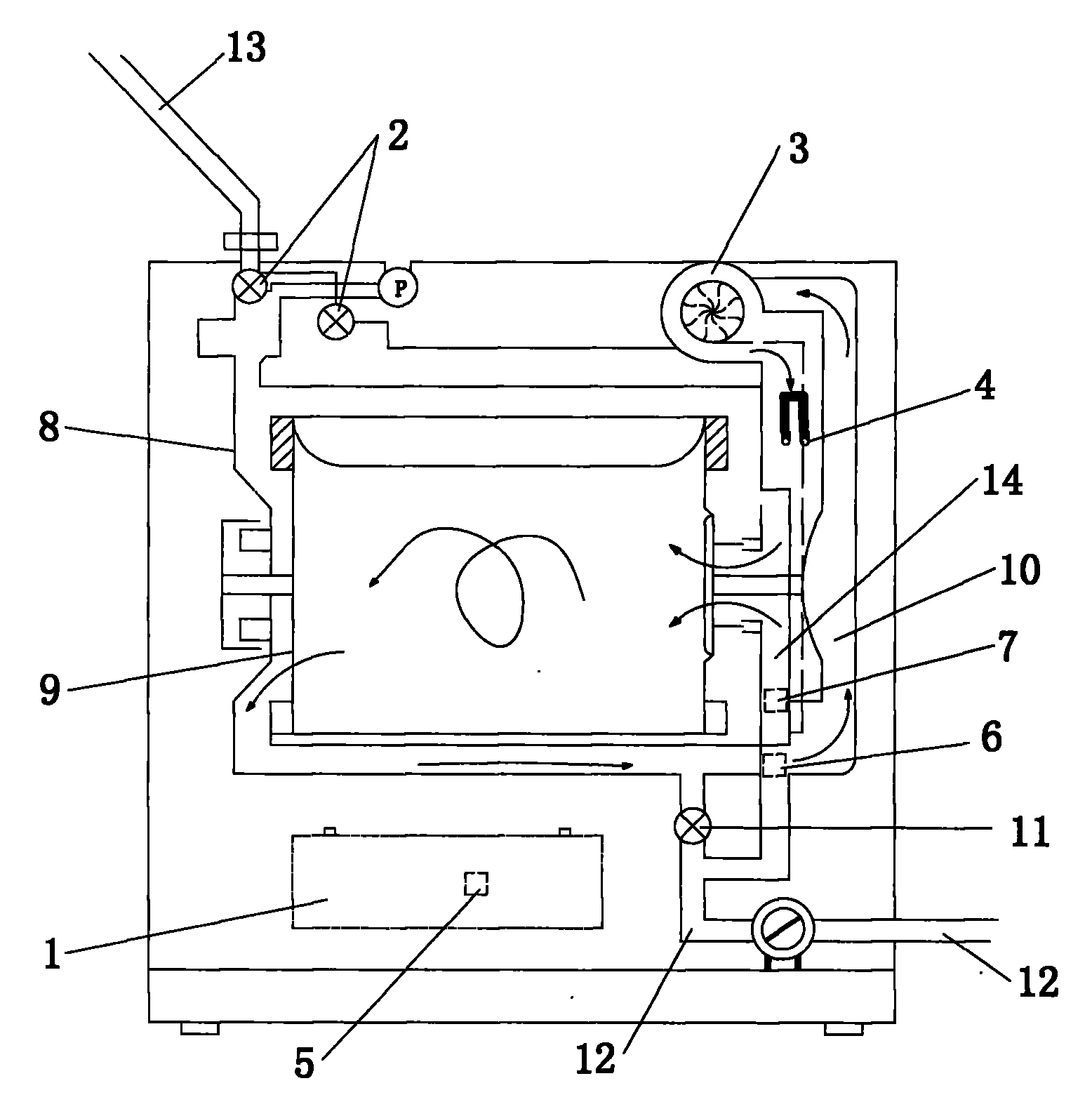

[0020] Such as figure 1 and figure 2 As shown, a drying control method of a water-saving washing machine that stops immediately after drying comprises the following steps: first, when starting to dry, the heater 4 and the drying fan 3 work simultaneously, and the inner cylinder temperature sensor 7 pairs The temperature of the hot steam in the washing machine inner cylinder 9 is detected to determine whether the temperature is lower than the set first opening temperature, if the judgment result is yes, then close the dehumidification pipe inlet valve 2, otherwise, open the dehumidification pipe inlet valve 2; Second, the dehumidification water in the dehumidification pipe 10 exchanges heat with the hot steam in the inner cylinder 9, and it is judged whether the temperature of the hot steam in the inner cylinder 9 is lower than the set second opening temperature, and if the judgment result is yes, the dehumidification is turned off Pipe water inlet valve 2, otherwise return t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com