Counter-flow heat exchange core body for fresh air ventilator

A technology of counter-flow heat exchange and fresh air ventilator, which is applied in the direction of heat exchanger, heat exchanger type, heat exchanger shell, etc., can solve the problem that the effect of cross-flow heat exchange is not as good as that of counter-flow, restricting the development of fresh air ventilator and Popularization, increase in resistance pressure drop, etc., achieve the effect of reducing weight and cost, simple structure, and reducing resistance pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is further described:

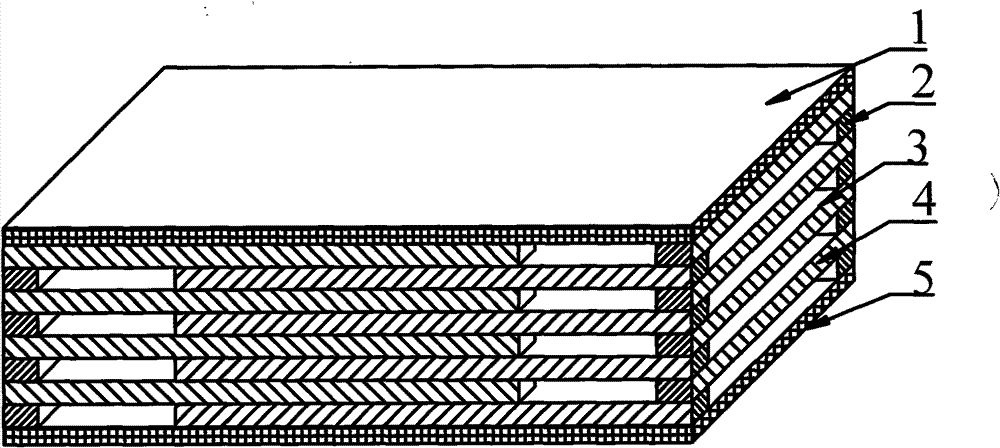

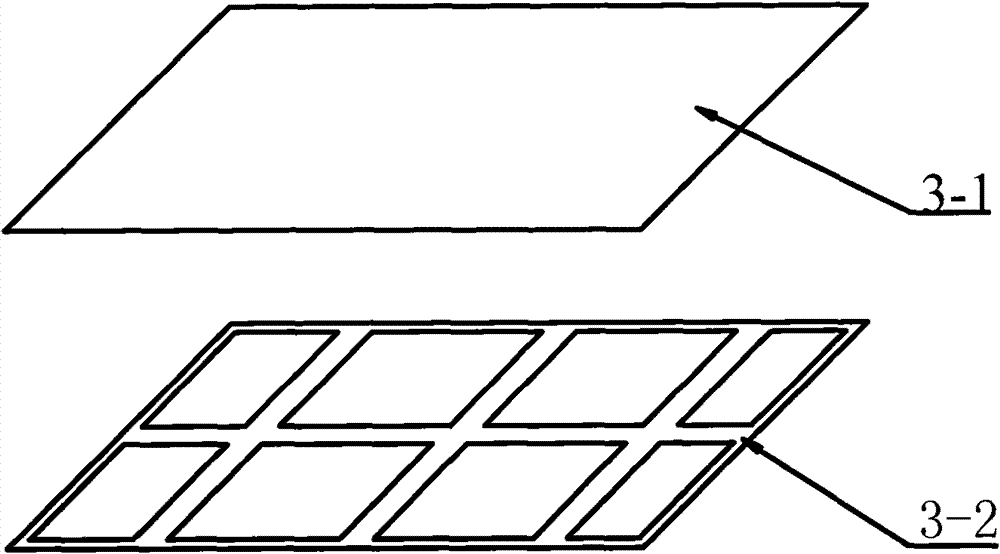

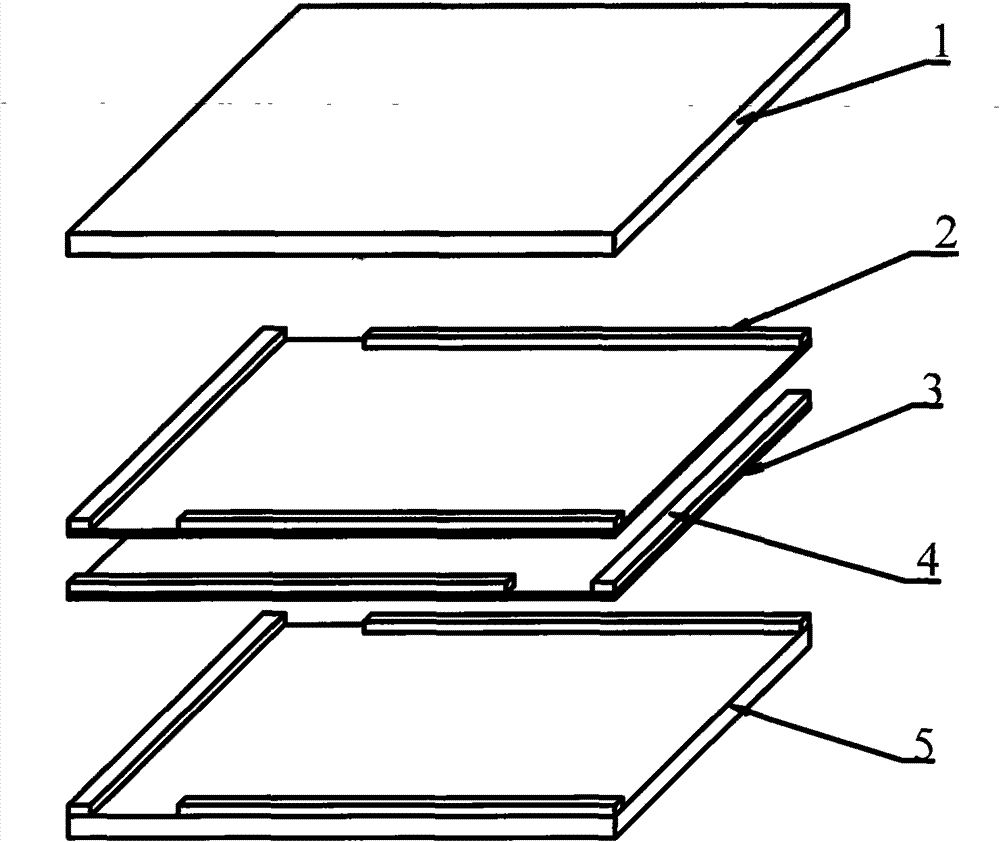

[0028] A counter-flow heat exchange core body for a fresh air ventilator, which is composed of a top plate 1, a bottom plate 5 and 2-500 heat exchange units of the same shape. The heat exchange unit is composed of a heat exchange diaphragm 3, an end seal 4 and two The root and side seals are composed of 2. The end seal is arranged on the upper surface of one end of the heat exchange diaphragm, and one end of the side seal is flush with the other end of the heat exchange diaphragm and is arranged on the upper surface of the side of the heat exchange diaphragm. The length of the seal is 9 / 10-1 / 2 of the side length of the heat exchange membrane. The heat exchange membrane is composed of a full heat exchange paper 3-1 and a support frame with holes 3-2. The adjacent heat exchange units Stacked at 180 degrees and fixedly connected, the top plate is fixedly set above the uppermost he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com