Robot for cleaning inner wall of barrel

A robot and gun barrel technology, applied in the field of mechanical devices, can solve the problems of complicated installation, inability to achieve positioning and scrubbing of residues on the inner wall of the gun barrel, etc., and achieves the effects of strong adaptability, stable and reliable scrubbing effect, and meeting the requirements of battlefield use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

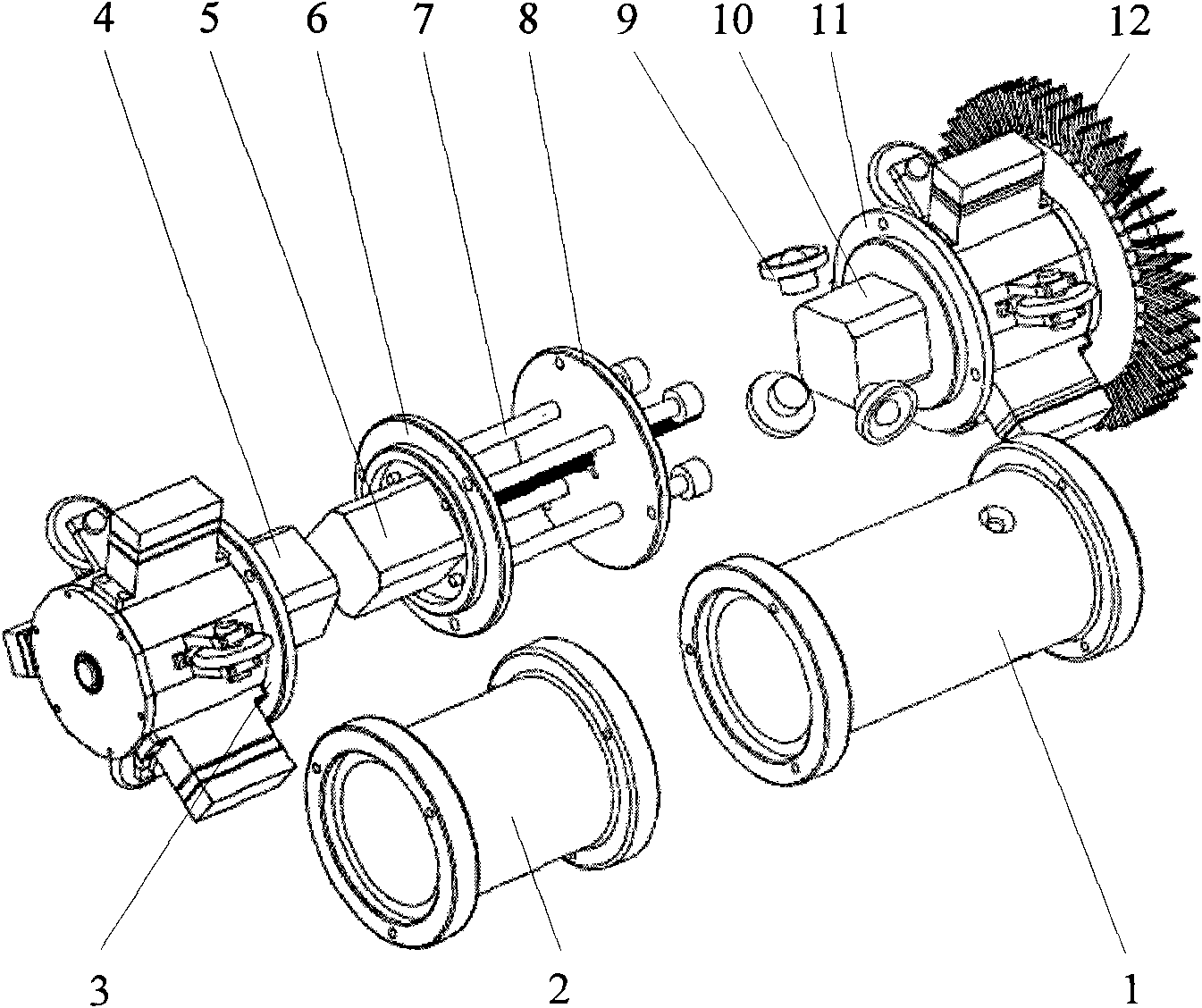

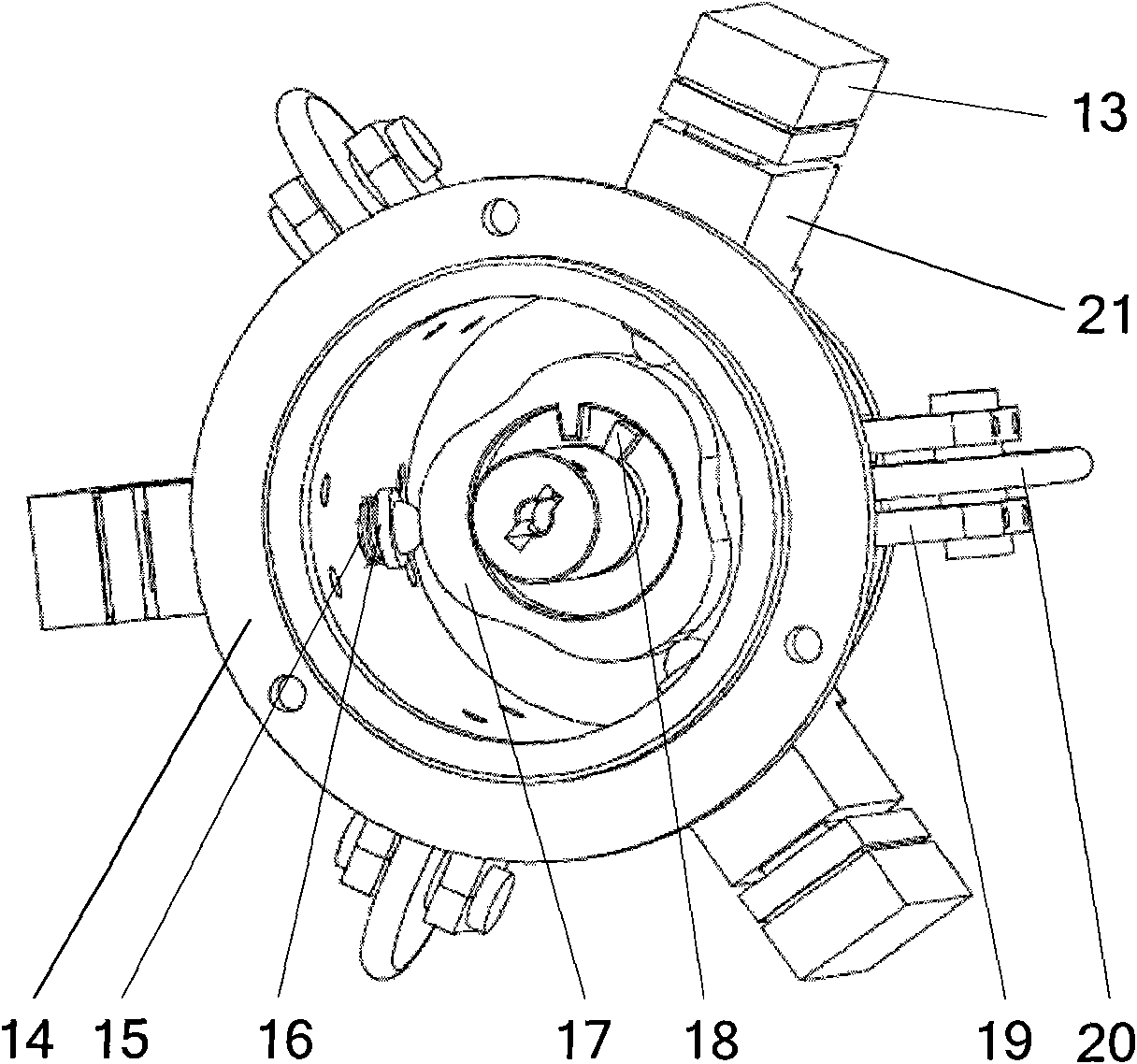

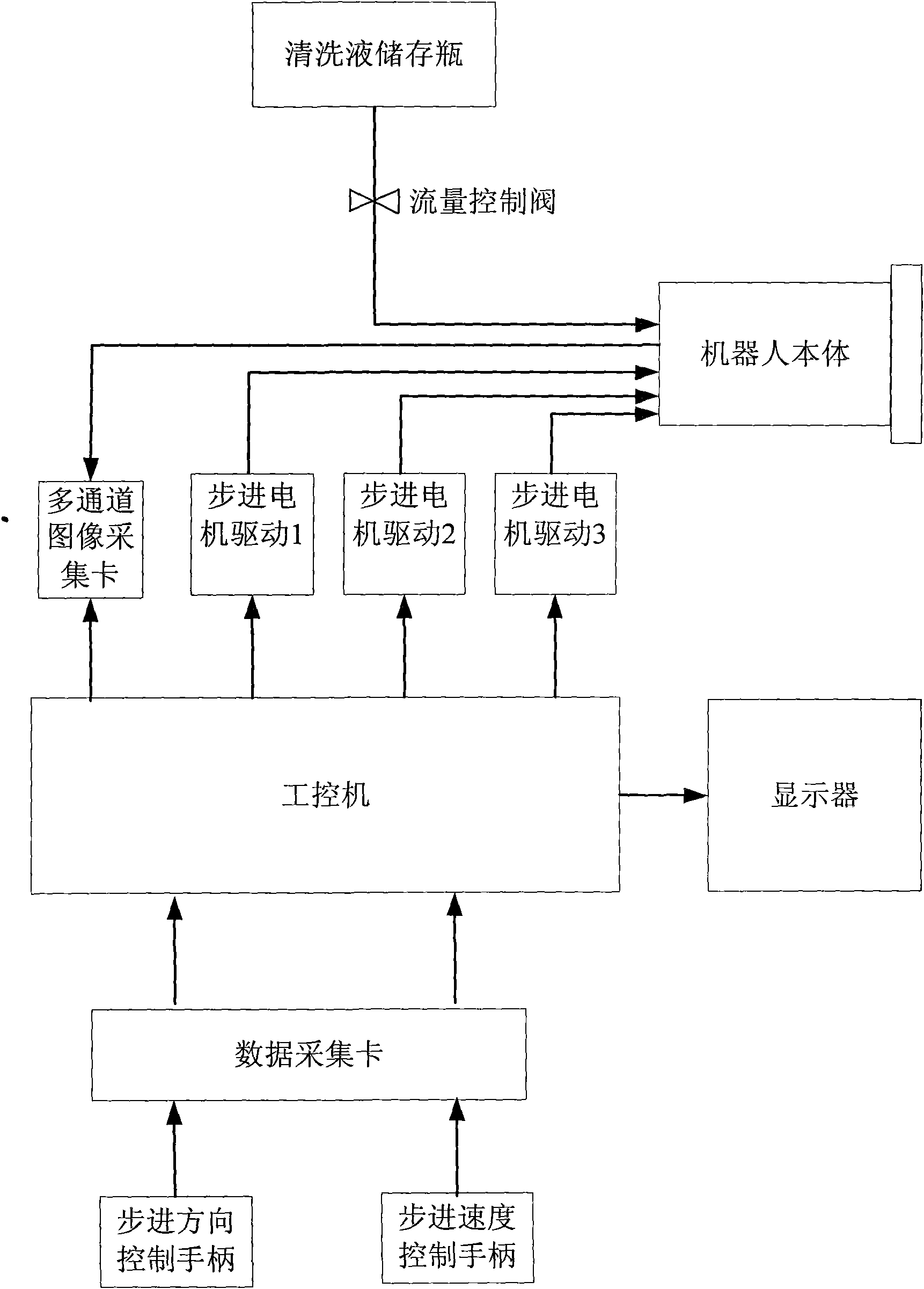

[0011] to combine figure 1 , the gun barrel inner wall scrubbing robot of the present invention includes a cleaning module and a driving module, and the two modules realize relative telescopic movement through a threaded transmission mechanism. Drive mechanism 11, cleaning brush 12, wherein the cleaning brush 12 is installed on the output shaft of the front compound drive mechanism 11, the front compound drive mechanism 11 is connected with the sliding plate 8 processed with the central internal thread hole through the front shell 1, and the front step The motor 10 is arranged in the front shell 1 and is used to drive the front composite drive mechanism 11; the drive module includes the rear shell 2, the rear composite drive mechanism 3, the rear stepping motor 4, the stepping motor 5 for moving, the motor fixing plate 6, and the guide rod 7, wherein the rear composite drive mechanism 3 is connected with the motor fixing plate 6 through the rear housing 2, the rear stepping mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com