Method for reducing station service power consumption rate of thermal power generating units

A technology of thermal power generation unit and plant power consumption rate, which is applied in data processing applications, instruments, calculations, etc., can solve problems such as reducing the power consumption rate of thermal power generating units in the factory, save troubleshooting time, avoid the number of on-site maintenance, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

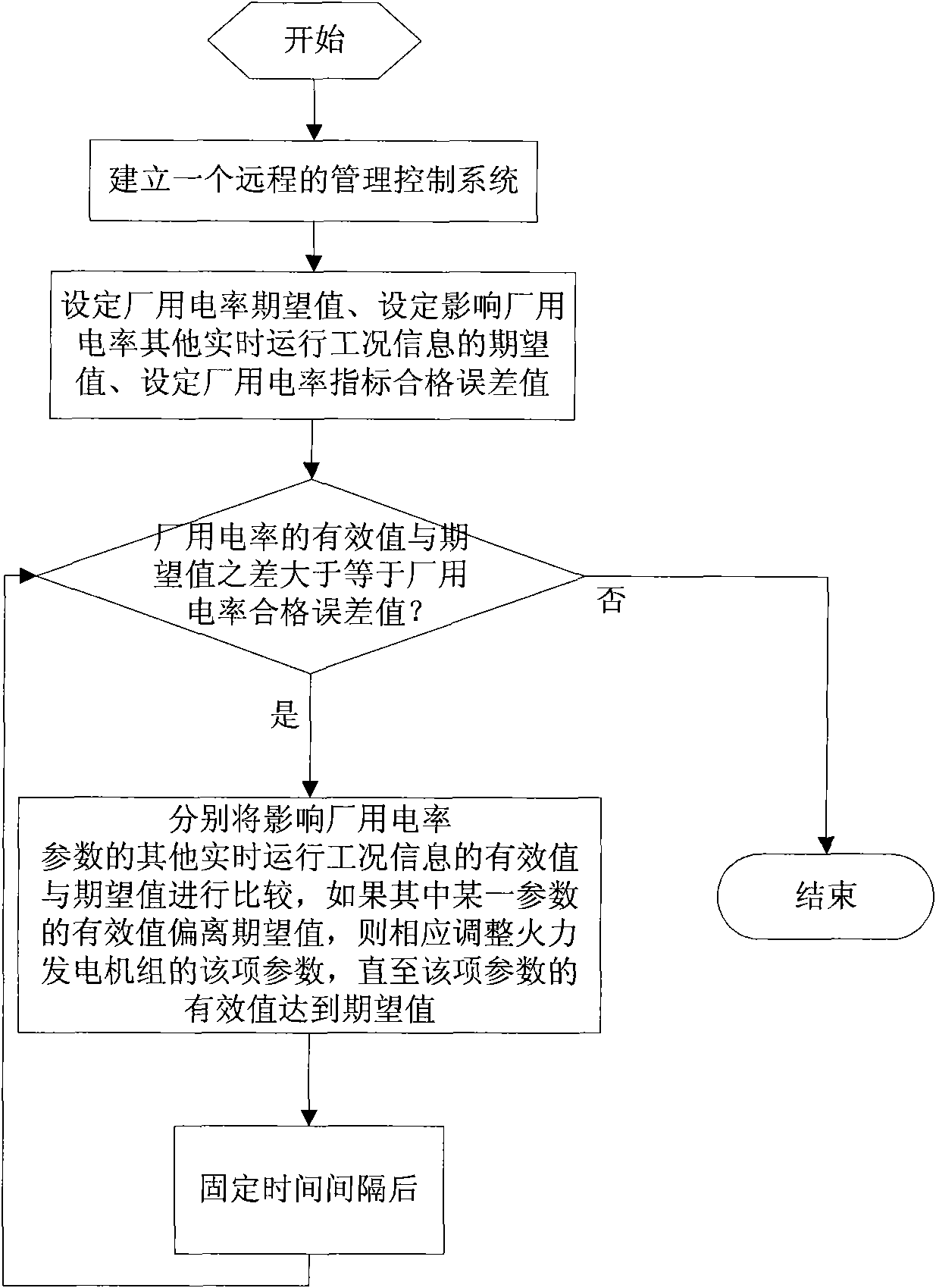

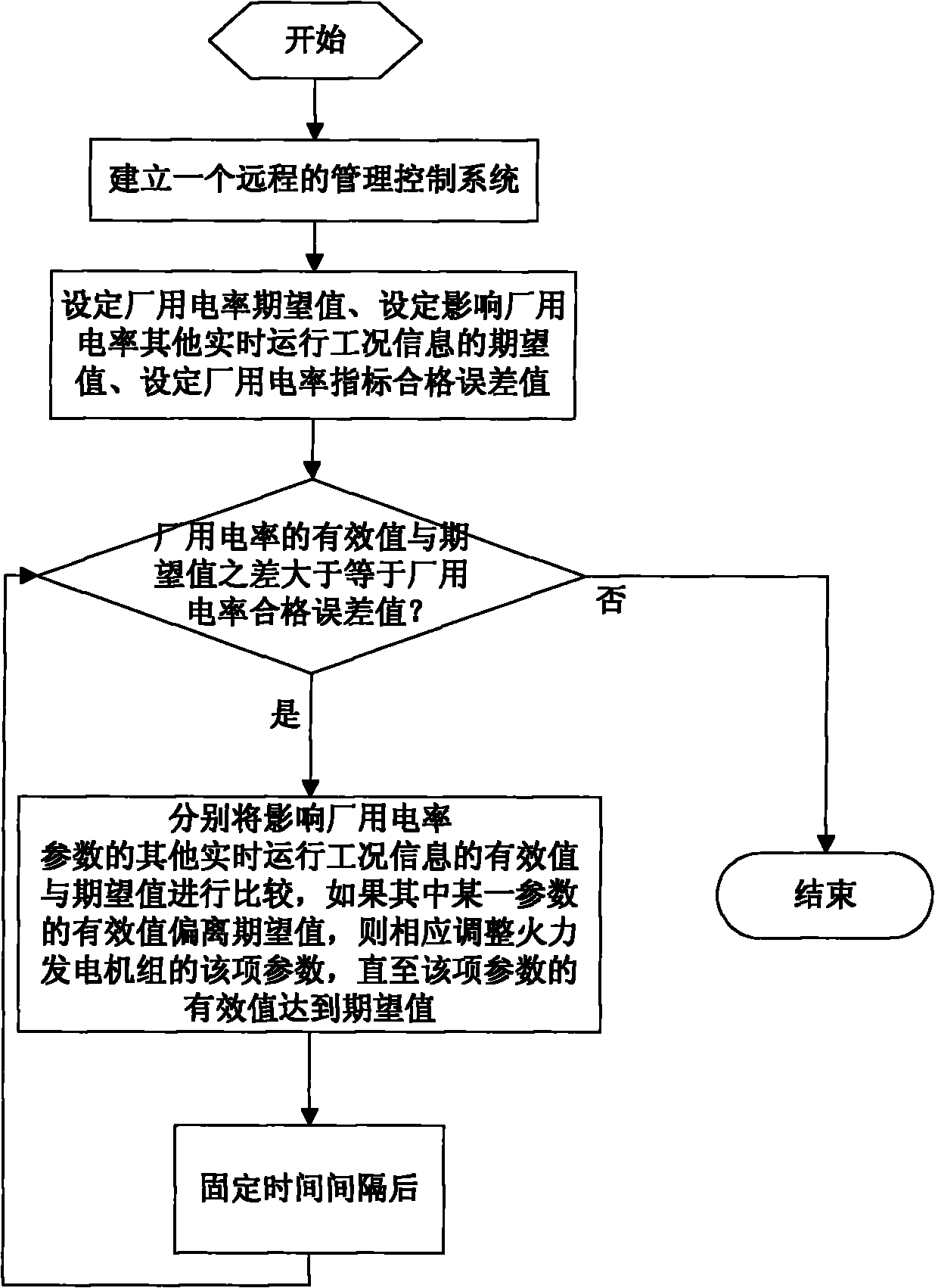

[0029] The invention provides a method for reducing the power consumption rate of thermal power generating units, see figure 2 As shown, it includes the following steps:

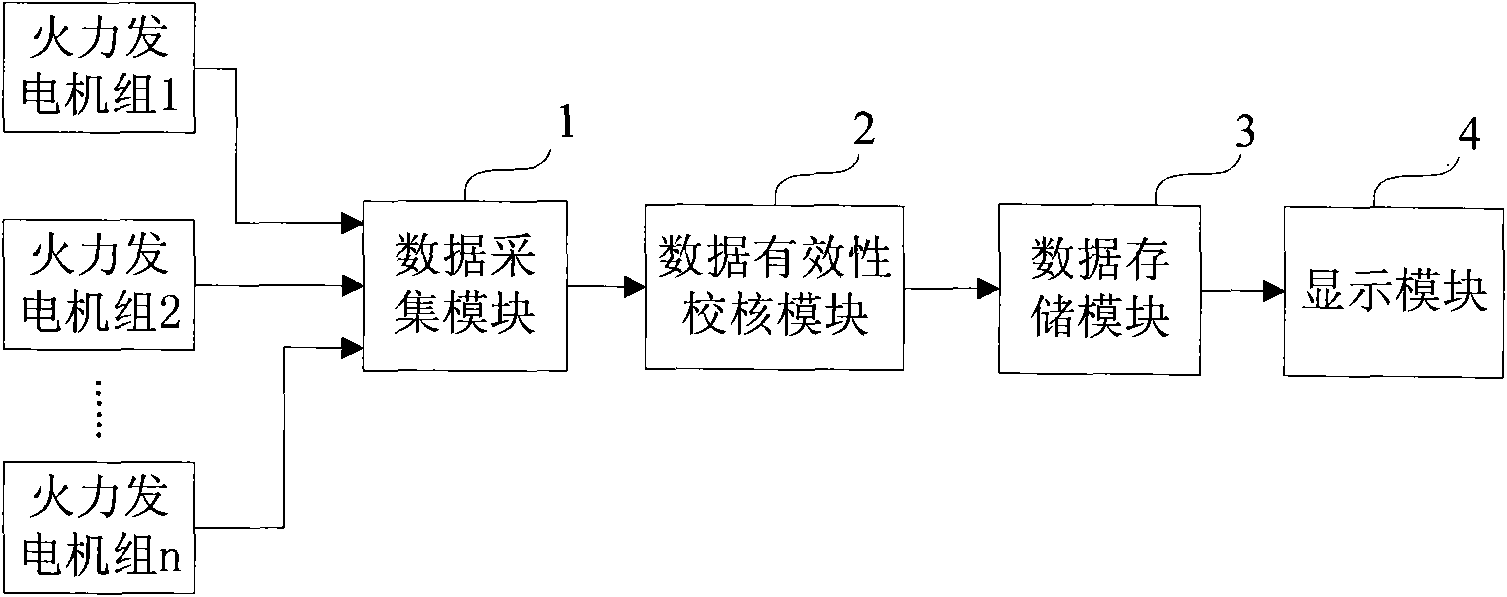

[0030] Step 1: Establish a remote management and control system, see figure 1 As shown, the management control system includes

[0031] The data collection module 1 can at least be used to collect the original value of the power consumption rate of thermal power generating units on the power generation site and other real-time operating condition information that can affect the parameters of the power consumption rate; the data collection module 1 can simultaneously collect multiple thermal power The utility power consumption rate of the generator set and other real-time operating condition information that can affect the utility power consumption rate parameters;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com