Control system of grain filler device

A control system, grain technology, applied in electrical program control, program control in sequence/logic controllers, food preparation, etc. Service life and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

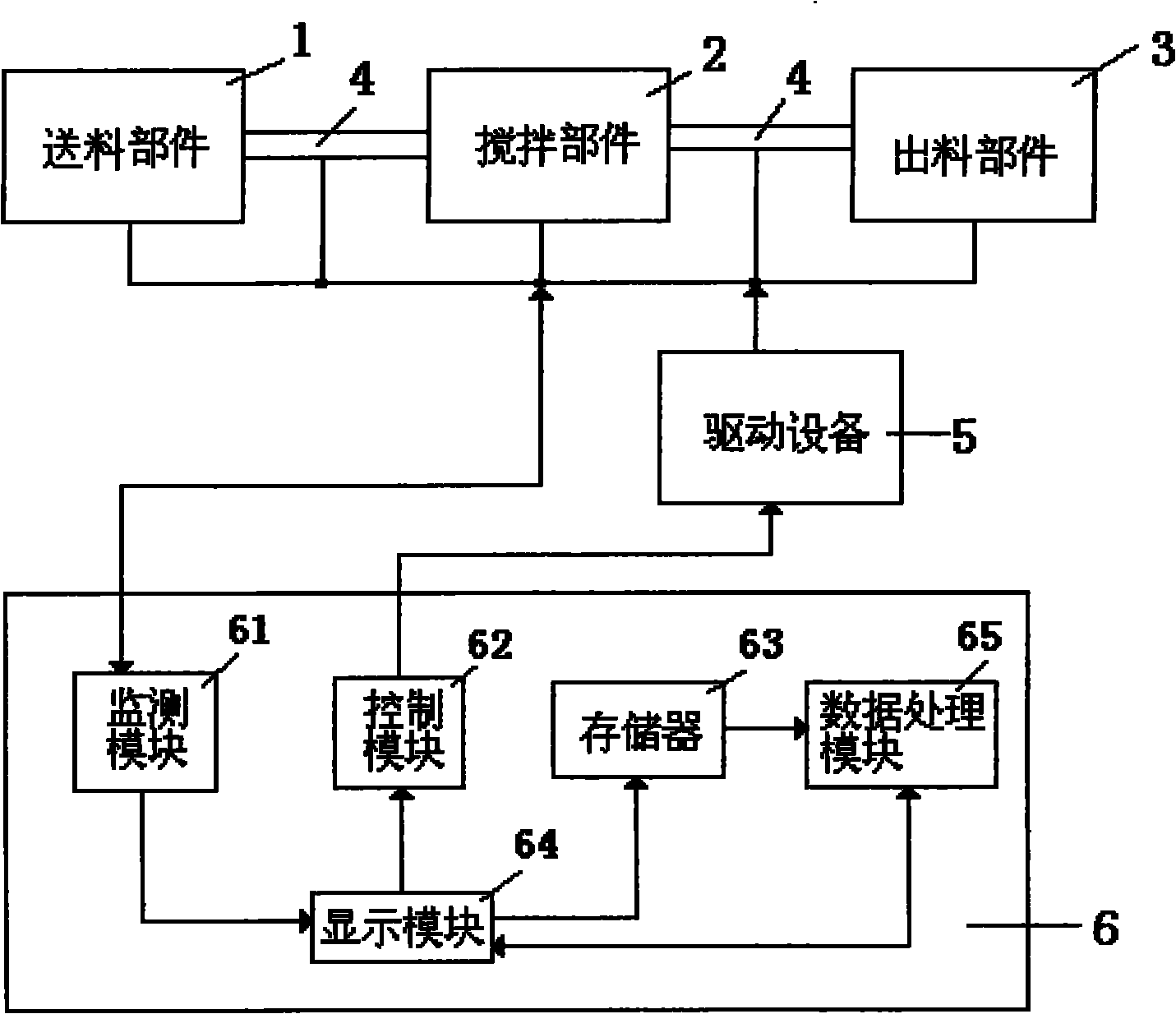

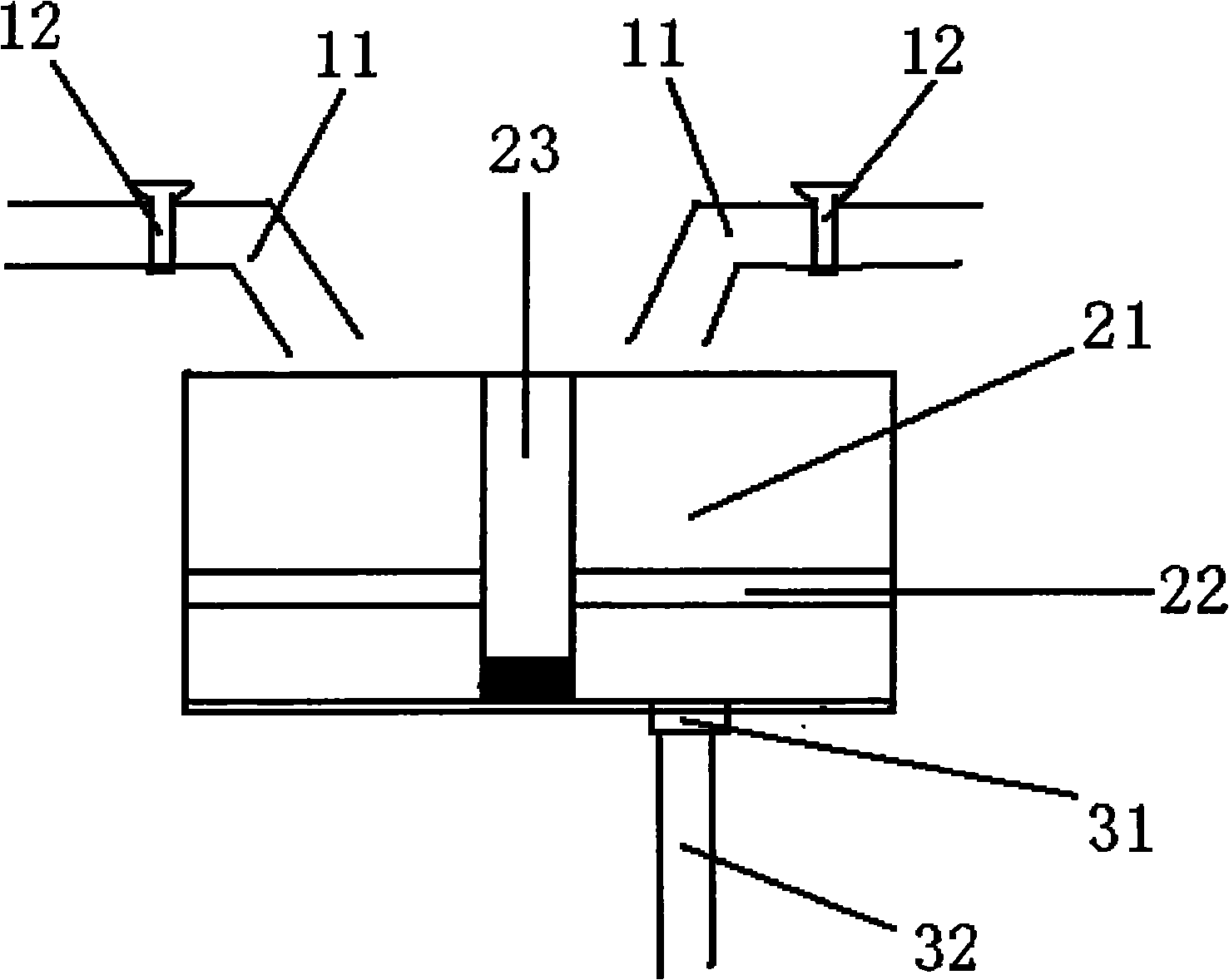

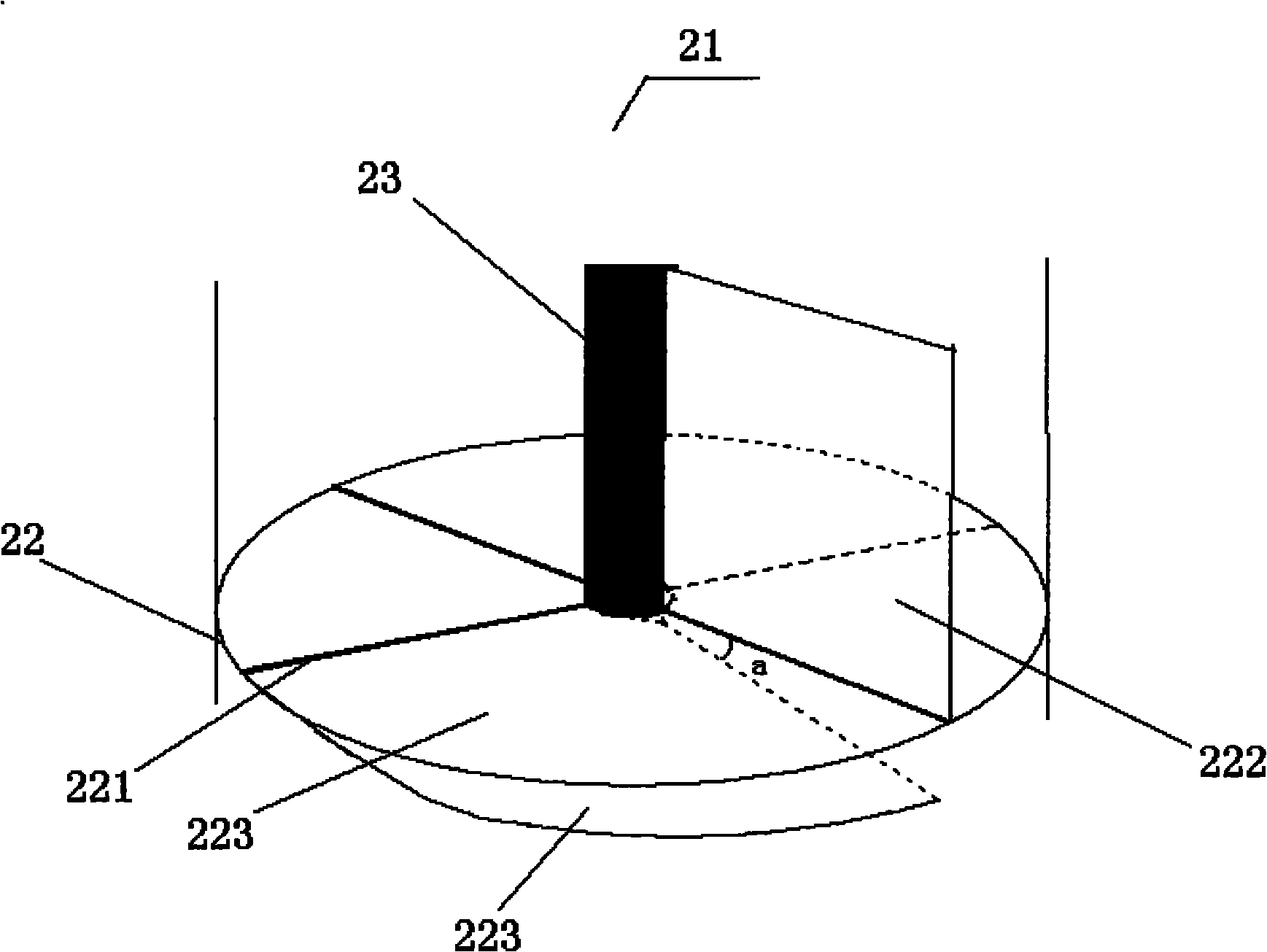

[0020] see figure 1 , a control system of a complete set of grain crushing device, including a material selection component 1, a stirring component 2, a discharge component 3, a sealed conveying channel 4, a driving device 5 and a central server 6.

[0021] The material selection part 1, the stirring part 2 and the discharge part 3 are arranged in sequence, and the parts are connected by a sealed delivery channel 4, and the material selection part 1, the stirring part 2 and the discharge part 3 are respectively connected with the driving equipment 5, The central server 6 is connected; the sealed conveying channel 4 is connected to the driving device 5 , and the driving device 5 is connected to the central server 6 .

[0022] The central server 6 includes a monitoring module 61 , a control module 62 , a memory 63 , a display module 64 and a data processing module 65 .

[0023] The monitoring module 61 is connected with the display module 64 to transmit the operating conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com